Methods for treating deodorizer distillate

A distillate and distillate technology, applied in the field of distillate processing, can solve the problems of expensive, dangerous mineral acid, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

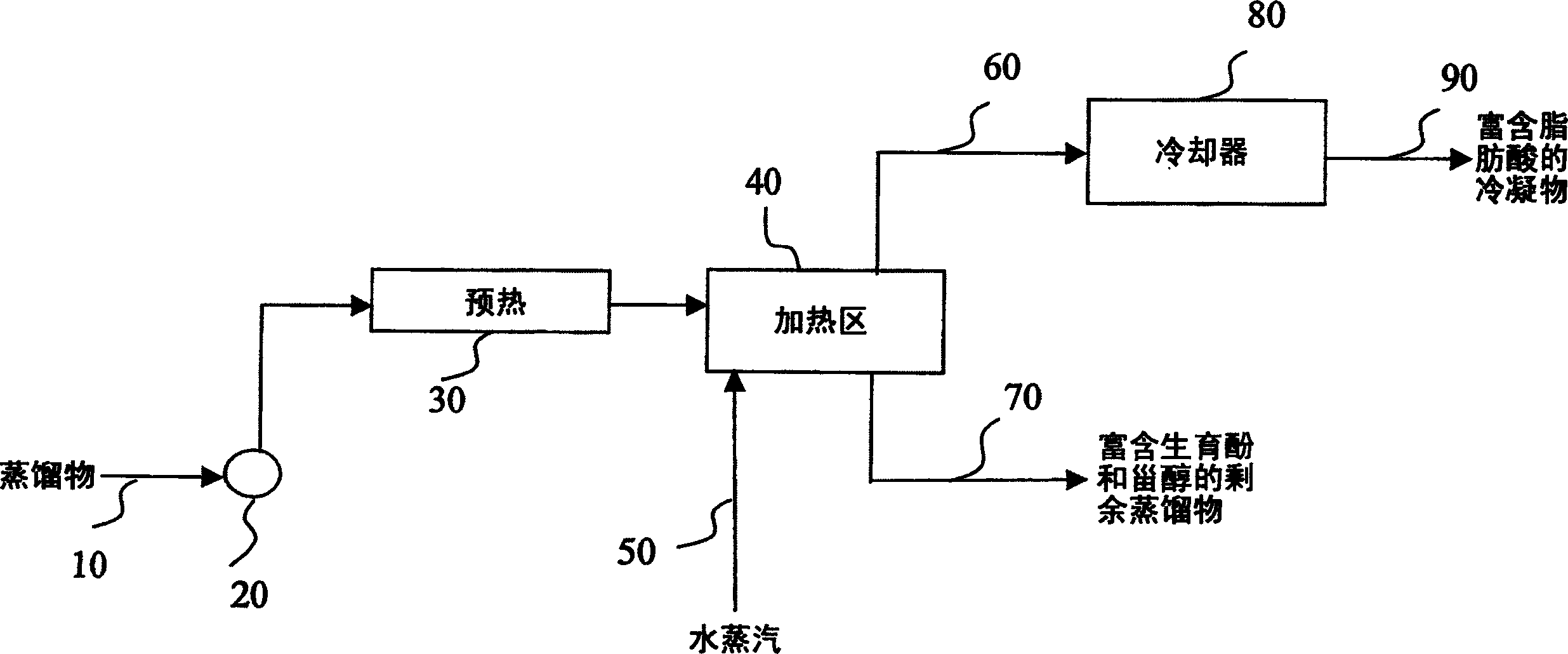

Embodiment 1

[0074] The distillate obtained after deodorizing soybean oil containing about 30.2% by weight free fatty acids, 16.6% by weight tocopherols and 17.6% by weight sterols and having a temperature of about 150°F is introduced into the heating zone at a rate of 60 gallons per hour In the middle, the temperature is raised to 450°F, and the vapor phase and the remainder of the distillate are obtained. The vapor phase was collected and cooled with a condensate production rate of about 20 gallons per hour containing about 75% by weight fatty acids, 5% by weight tocopherols and 2% by weight sterols. The remaining fraction of the distillate was produced at 40 gal / hr and contained about 4.1% by weight fatty acids, 21.5% by weight tocopherols and 20.1% by weight sterols.

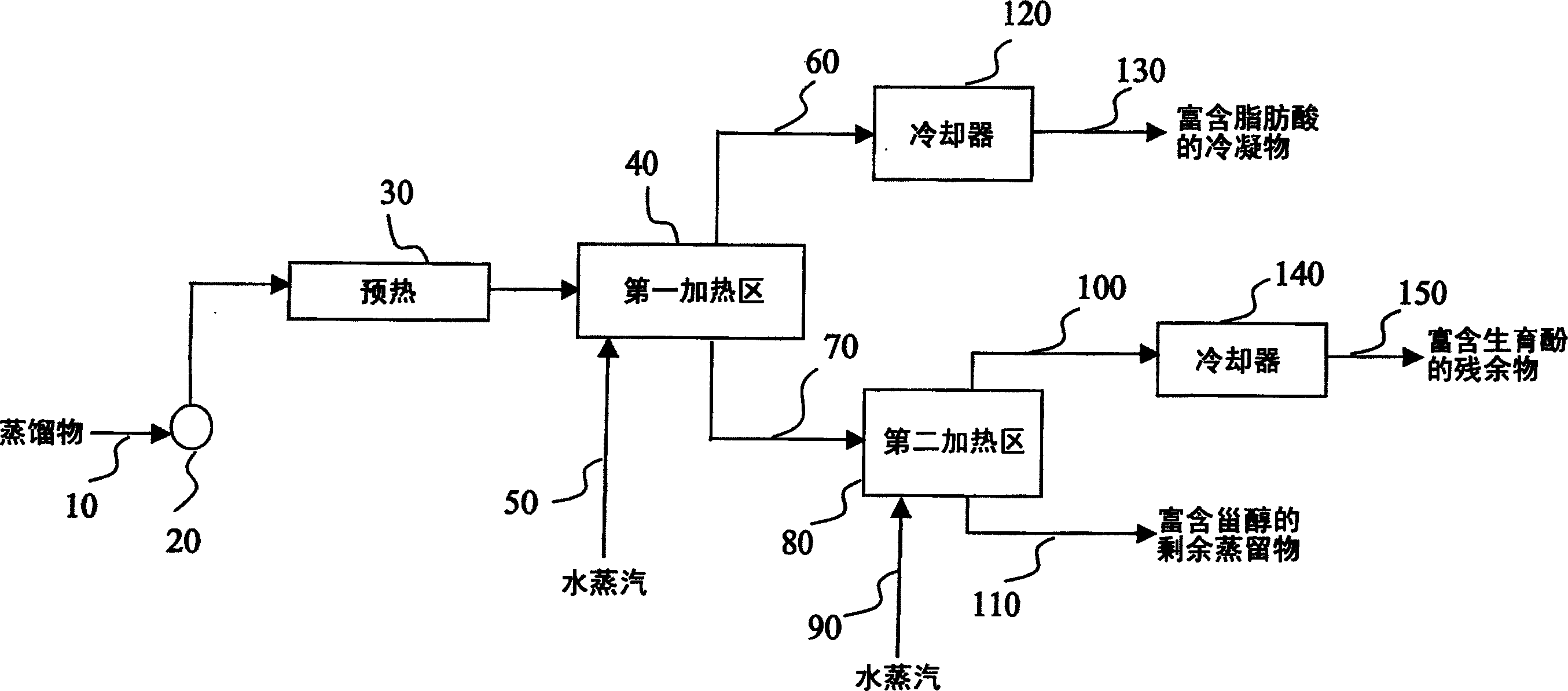

Embodiment 2

[0076] The distillate obtained after deodorizing soybean oil containing about 30.2% by weight free fatty acids, 16.6% by weight tocopherols and 17.6% by weight sterols and having a temperature of about 150°F is introduced into the heating zone at a rate of 60 gallons per hour In the middle, the temperature was raised to 450°F to obtain the vapor phase and the remainder of the distillate. The collected and cooled vapor phase had a condensate generation rate of about 20 gallons per hour and contained about 77.7% by weight fatty acids, 4.9% by weight tocopherols and 1.7% by weight sterols. The remaining fraction of the distillate produced 40 gal / hr and contained about 0.8% by weight fatty acids, 20.7% by weight tocopherols and 17.1% by weight sterols.

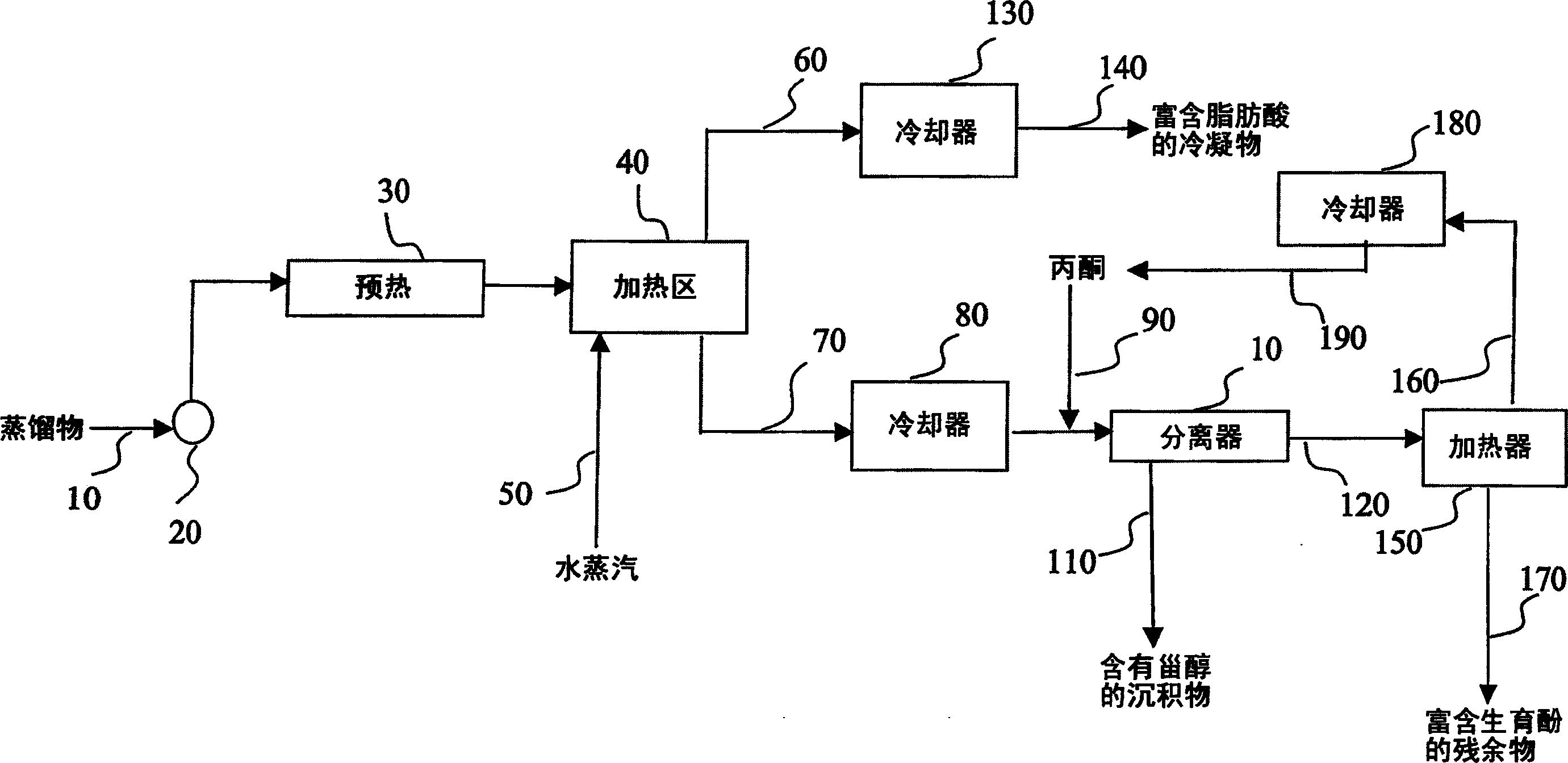

Embodiment 3

[0078] The remainder of the distillate from Example 2 was cooled to ambient temperature, then mixed with acetone in a 1:1 ratio, and the mixture was centrifuged to obtain a sterol-containing sediment and a tocopherol-containing solvent phase. Evaporation of acetone in the solvent phase yields a tocopherol-rich residue. The sterol-containing deposits included about 1.57% by weight fatty acids, 6.29% by weight tocopherols and 76.46% by weight sterols. The tocopherol-rich residue contained 11.31% by weight fatty acids, 42.97% by weight tocopherols and 18.87% by weight sterols.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com