Method for processing recovered wax

A processing method and wax recovery technology, which is applied in the direction of recycling technology, fat material recovery, fat material recovery/refining, etc., can solve problems such as waste, voids in the finished wax model, and recycled wax does not contain, etc., to reduce processing The effect of working hours, improving work efficiency and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

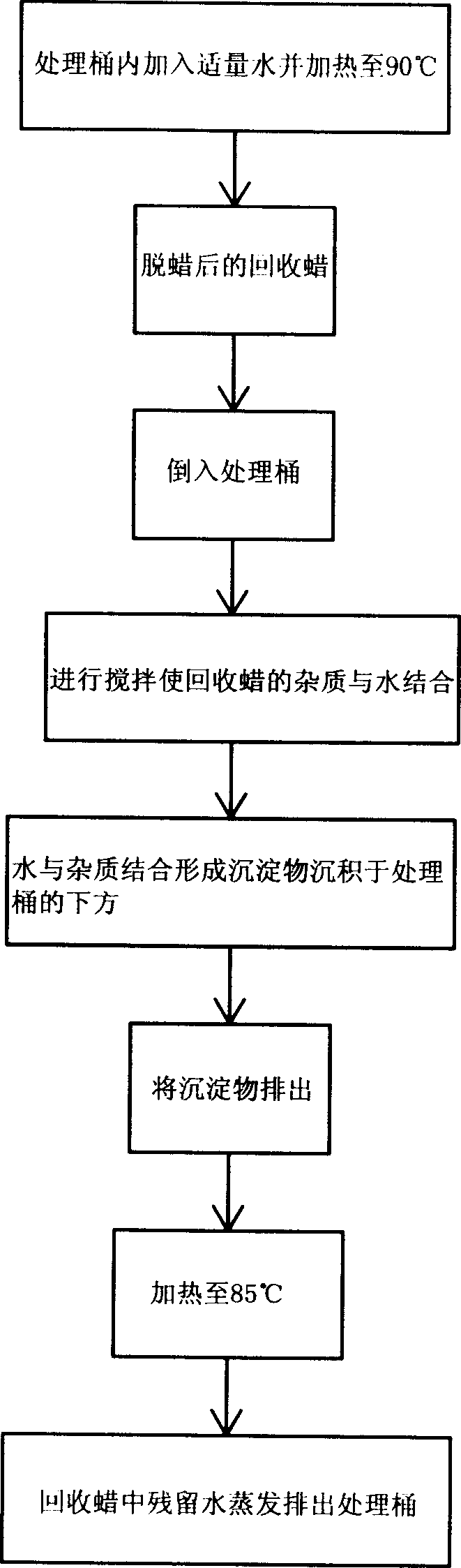

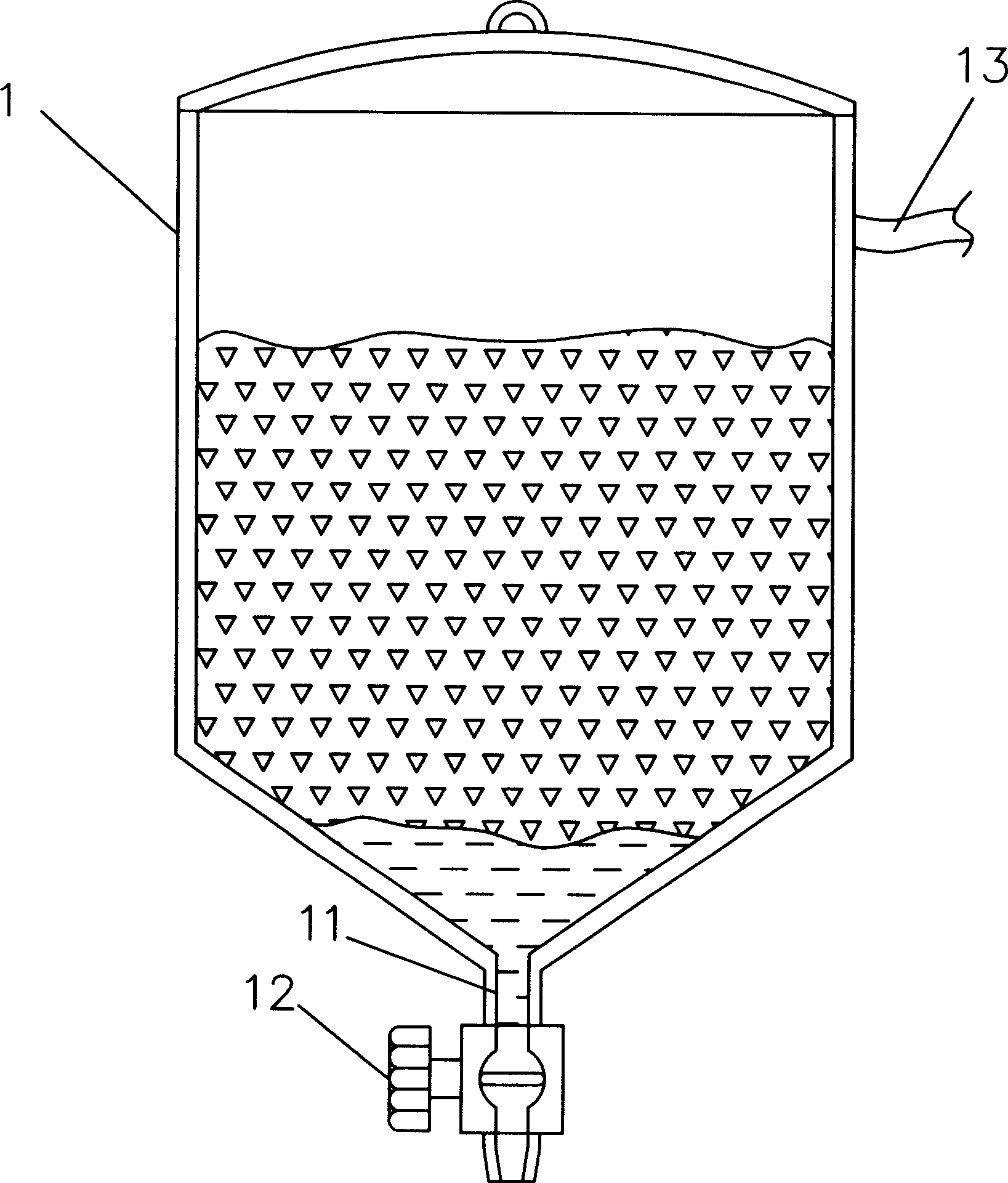

[0017] Embodiment 1, the present invention handles the method for reclaiming wax, please refer to figure 2 , image 3 Firstly, 10% is added into a treatment tank 1, and the water is heated to 85°C at the same time, then, the recovered wax from the dewaxing operation is poured into the treatment tank 1, and the recovered wax can be made into a liquid state by the heated water. Again, a discharge pipe 11 is established below the processing barrel 1, the discharge pipe 11 is provided with a switch valve 12 that can reach the function of closing and opening, and a vacuum pipe 13 is provided at the top of the side wall of the processing barrel 1, and then after adding water Stir the recovered wax, and let it carry out a self-precipitation after stirring, by the action of adding water and stirring, most of the water in the treatment tank 1 can be combined with the impurities in the recovered wax, because the water and impurities After combining, its specific gravity is much greate...

Embodiment 2

[0018] Embodiment 2, the water that adds in the treatment tank is 40%, and the water heating to temperature is 90 ℃ when advancing simultaneously, and when becoming vacuum in the treatment tank, heating temperature is 85 ℃, and all the other steps are with embodiment 1. It takes about 5 hours for the water to evaporate from the recovered wax after being heated, and the wax with a purity of 96% can be obtained.

Embodiment 3

[0019] Embodiment 3, add the water in the treatment tank to be 90%, and the water is heated to a temperature of 95° C., and when the treatment tank becomes a vacuum, the heating temperature is 90° C., and all the other steps are the same as in Example 1. It takes about 6 hours from heating to recovering the water in the wax to evaporate and discharge, and the wax with a purity of 95% can be obtained.

[0020] Using the treatment method of the present invention, not only can the water and impurities contained in the recovered wax be completely drained to obtain wax with higher purity, so when it is poured into the wax spray machine for wax mold manufacturing, the completed wax mold will not There are bad waxes, and the products made of wax molds will naturally not have gaps or excessive burrs, which can effectively reduce the defective rate and reduce costs. In addition, the existing simple heating and precipitation treatment takes more than 20 hours. time, and the processing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com