Oil dewaxing process and device

An oil and dewaxing technology, applied in the direction of oil/fat refining, fat production, and fatty substance recovery, etc., can solve the problems of low degree of automation, high production cost and high energy consumption, so as to reduce production cost, high degree of automation and equipment. The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

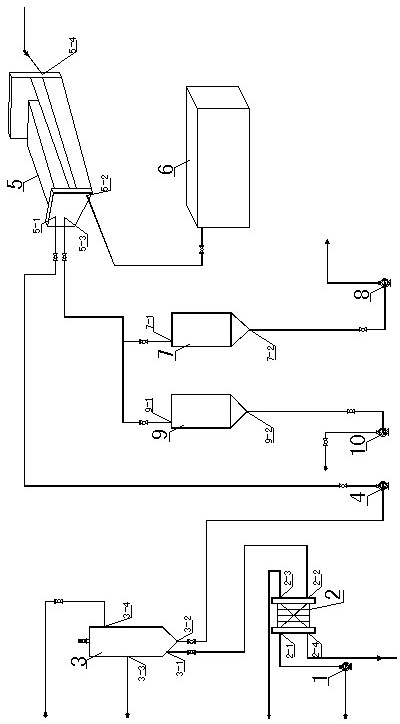

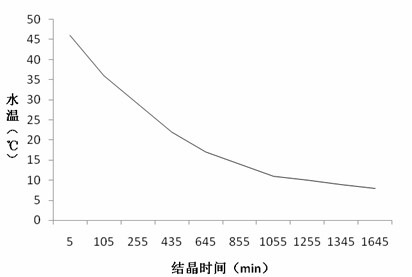

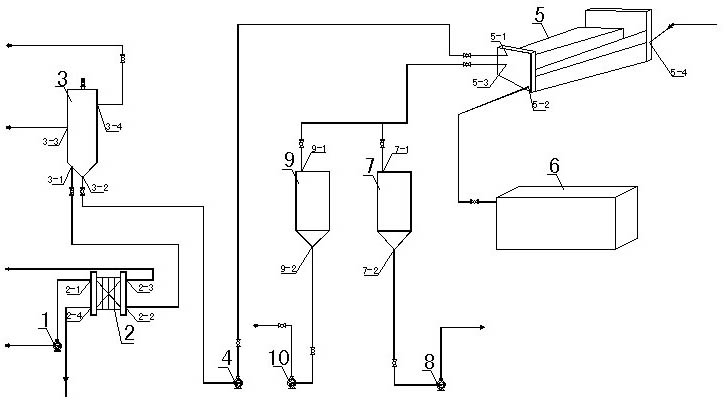

[0017] Such as figure 1 As shown in the oil dewaxing process, the oil to be dewaxed is pumped into the heater 2 through the feed pump 1 of the crystallization tank, and the oil is heated to 50°C to completely melt and enter the crystallization tank 3; Under the program control of the crystallization menu and the action of the cooling medium, it will finally drop to 6-18°C after 18-40 hours to complete the cooling, crystallization and crystal growth of the oil. The crystallization menu is shown in Table 1; the feed pump 4 of the diaphragm filter press and the diaphragm filter press The machine 5 is interlocked controlled, and the filtering process is automatically controlled, and the process of oil feeding, filtering, squeezing, purging, and cake unloading is automatically completed; the crystallized oil is pumped into the membrane filter press 5 through the membrane filter press feeding pump 4 Filter and separate, and the dewaxed grease flows into the dewaxed grease tank 7. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com