Device and method for dewaxing textile and recovering wax

A recovery equipment and recovery method technology, applied in the direction of fat material recovery, fat material recovery/refining, recycling technology, etc., can solve the problems of secondary pollution, high cost, etc., and achieve water saving, cost reduction, and pollution reduction Effect

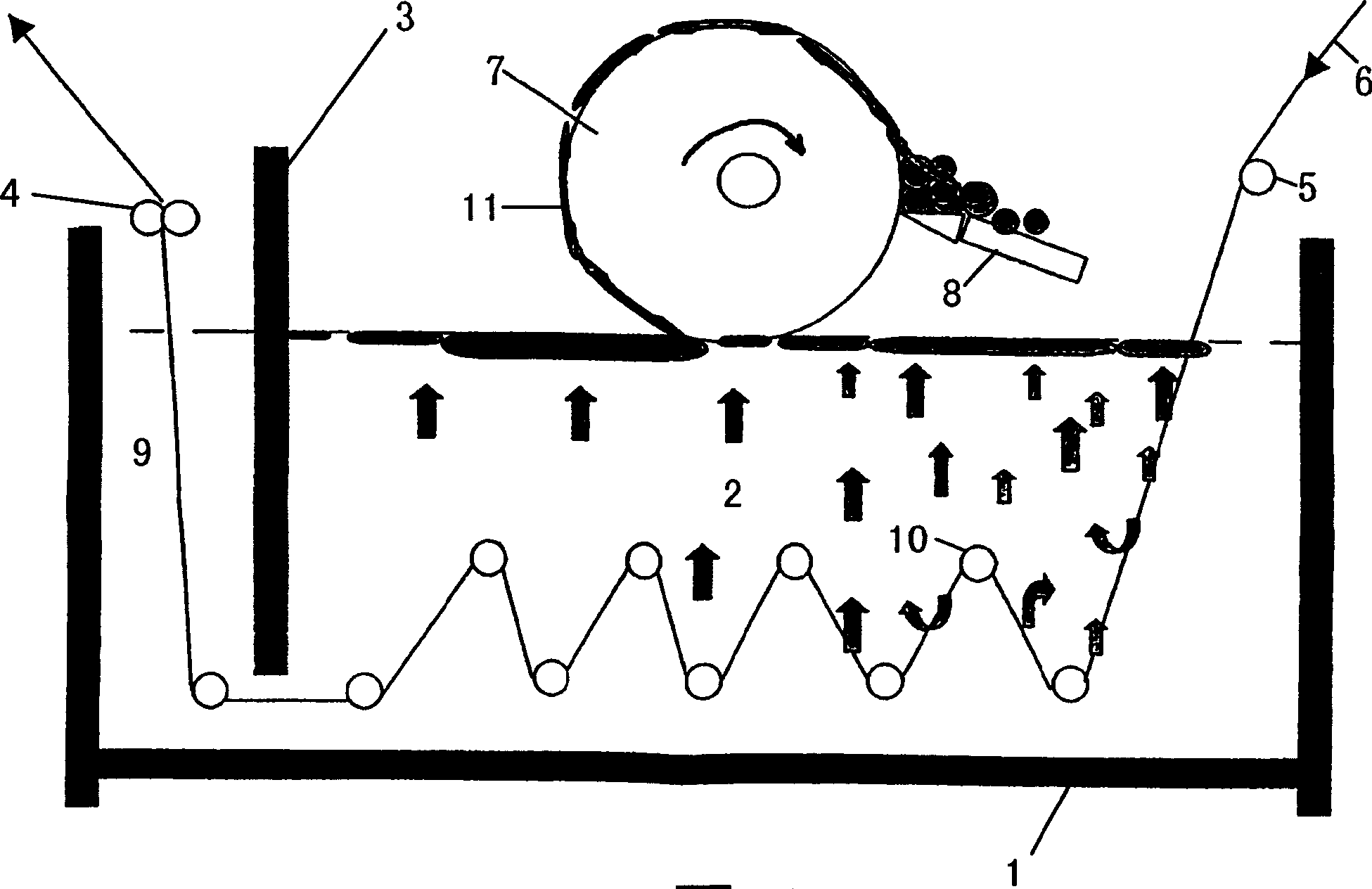

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0026] Wax recovery method

[0027] The above data shows that the wax recovery rate of the dewaxing tank of the invention is much higher than that of common air flotation recovery wax efficiency. Although the wax recovery rate of the dewaxing tank of this invention is slightly lower than the efficiency of organic solvent recovery wax, the cost of this invention recovery wax is much lower than organic solvent recovery wax, and it will not cause water bodies like the organic solvent recovery method Secondary pollution. Therefore, this invention combines the advantages of high-efficiency wax recovery and low cost.

experiment example 2

[0029] In order to show the quality of the recovered wax of this invention, the following experiments were done. Take the recovered wax directly to the waxing workshop to heat the wax at high temperature, then use the recovered wax to wax the fabric samples, and then dye the printed wax fabrics with indigo, waxing, waxing and dewaxing, etc. The fabric samples obtained from the new wax printing fabric are exactly the same as the batik fabric obtained from the new wax printing fabric. It is proved that the use performance of the wax recovered by the dewaxing equipment of the present invention is exactly the same as that of new wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com