Gas and electric heating assisted gravity oil drainage technology

An auxiliary gravity and electric heating technology, applied in the field of well completion and oil production, oil field drilling, can solve the problems of weak crude oil viscosity, heat loss, slow production speed, etc., to prevent heat concentration and water evaporation, high oil production volume and oil-gas ratio, and the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

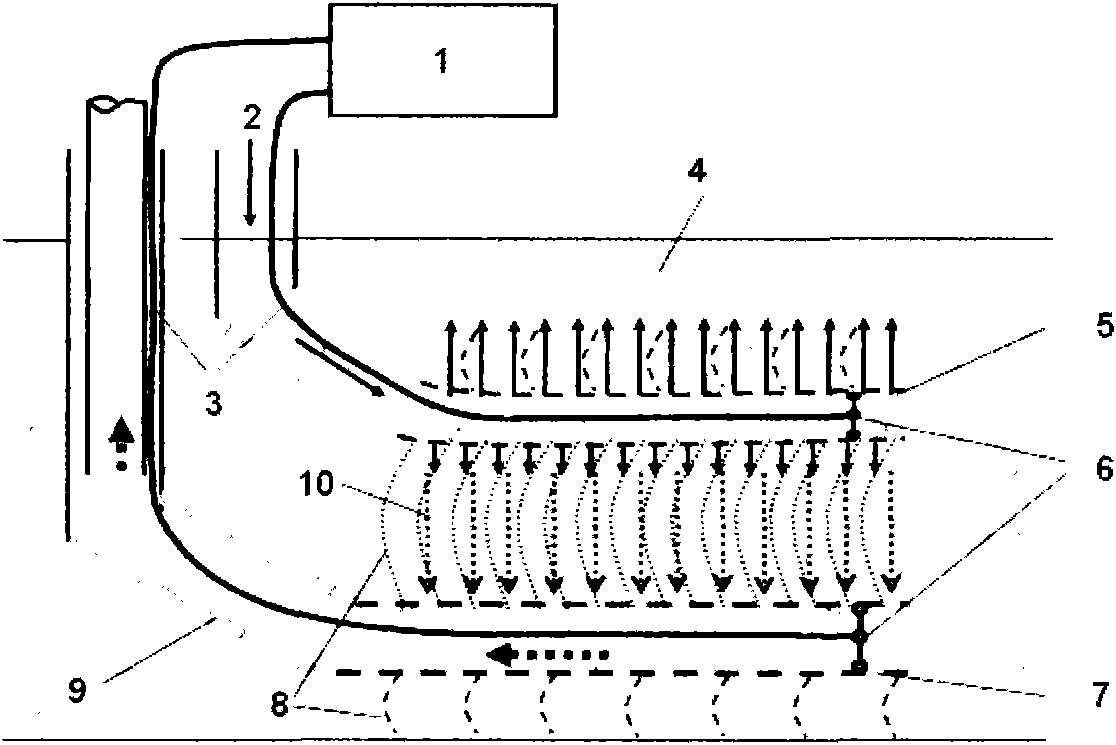

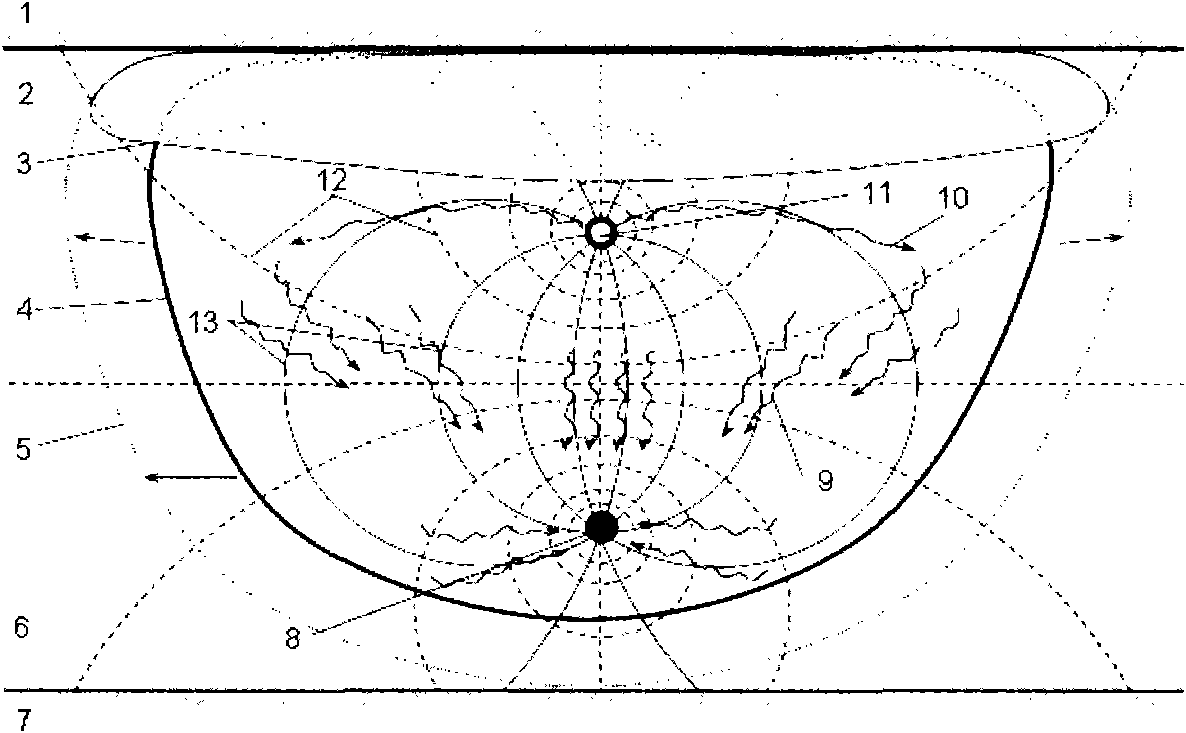

[0068] First follow the manual figure 1 Drill two horizontal wells arranged up and down, and complete the well with insulating casing or insulating screen at the heel of the horizontal section (or infill drilling a horizontal well parallel to the original horizontal well on the basis of the existing horizontal well, or the vertical section of the original horizontal well Sidetracking a new horizontal wellbore by opening a window (see attached picture). At this time, the original horizontal well needs to be insulated by casing milling in the vertical well section or the root, and the new well is directly completed with insulating casing or screen. See attached Figure 4 ). Then, the electrode (casing or screen) is connected to the surface power source using a temperature-resistant, oil-resistant and water-resistant cable and a special downhole expansion electrode connector. While the system is powered on, the upper well injects N 2 , CO 2 , flue gas or natural gas and other ...

Embodiment 2

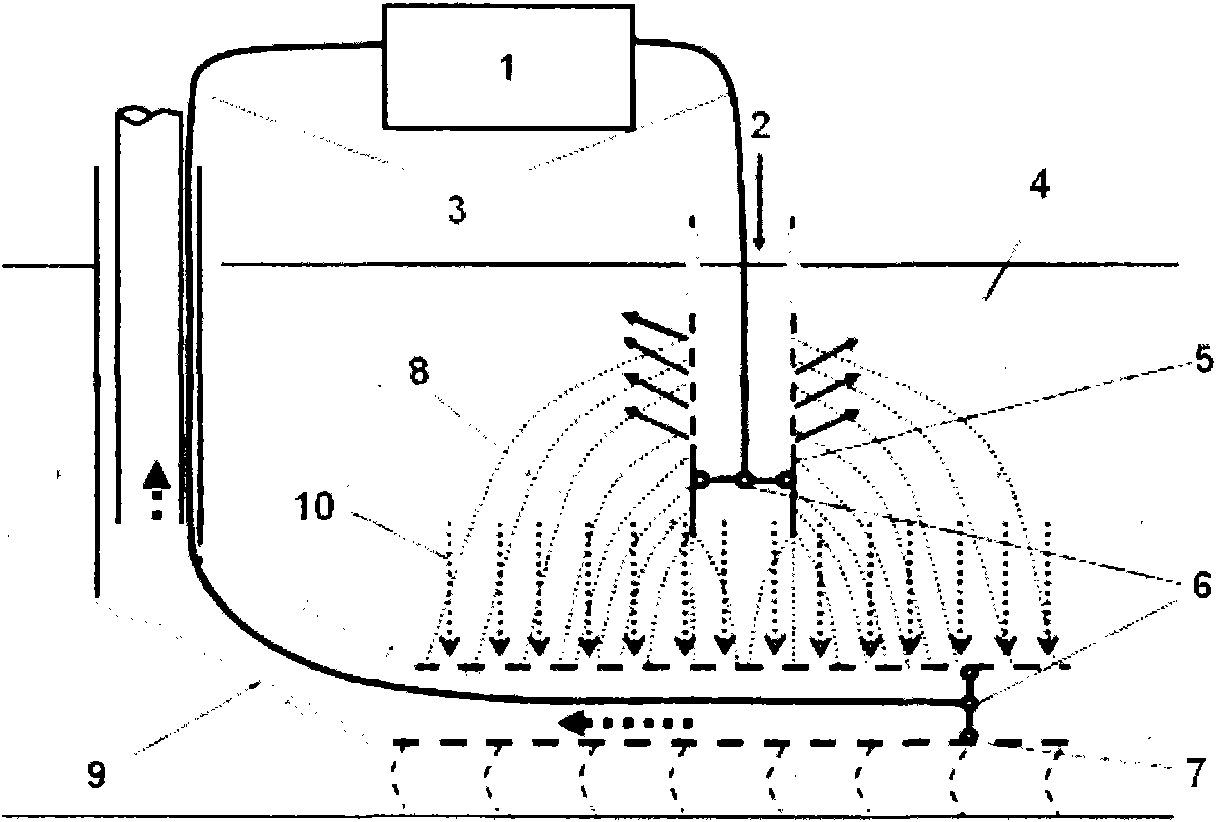

[0070] First follow the manual image 3 A vertical well is drilled in the upper part of the reservoir, and a horizontal well is drilled in the lower part of the reservoir. The position of the vertical well is generally selected between the middle and the end of the horizontal section of the lower horizontal well, and it can also be drilled outside the end for gravity-assisted oil displacement. This combination of vertical wells and horizontal wells can be realized by drilling additional horizontal or vertical wells on the basis of existing vertical or horizontal wells. Similarly, when completing the well, the upper part of the vertical well, the vertical section or the root of the horizontal well should be completed with insulating casing or insulating screen. Then, the electrode (casing or screen) is connected to the surface power source using a temperature-resistant, oil-resistant and water-resistant cable and a special downhole expansion electrode connector. While the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com