Apparatus and method for measuring small-sized cold compressor oil circulation amount

A technology of refrigeration compression and circulation, applied in pump testing, mechanical equipment, machine/engine, etc., can solve the problems of complex operation, inaccuracy, lack of data support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

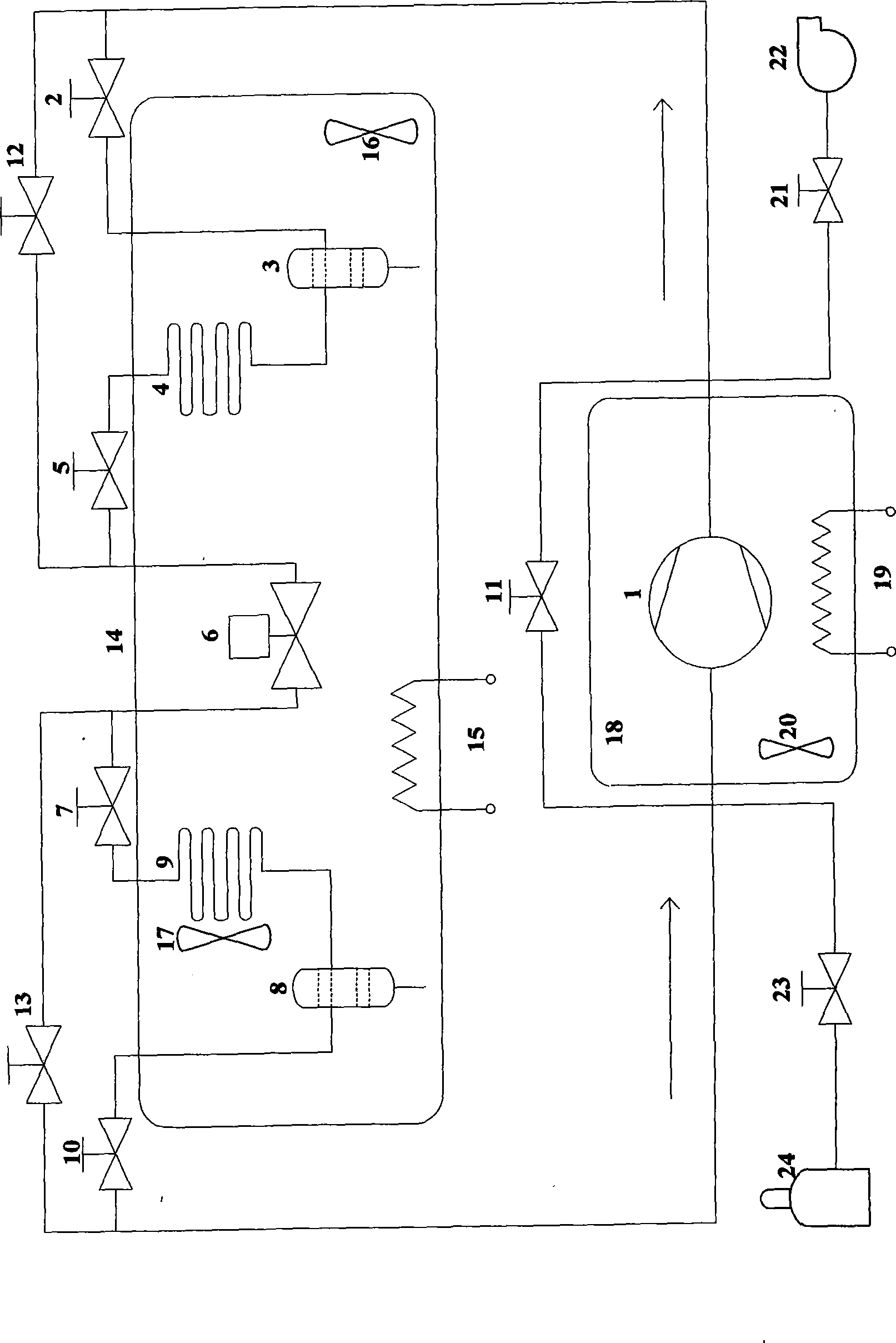

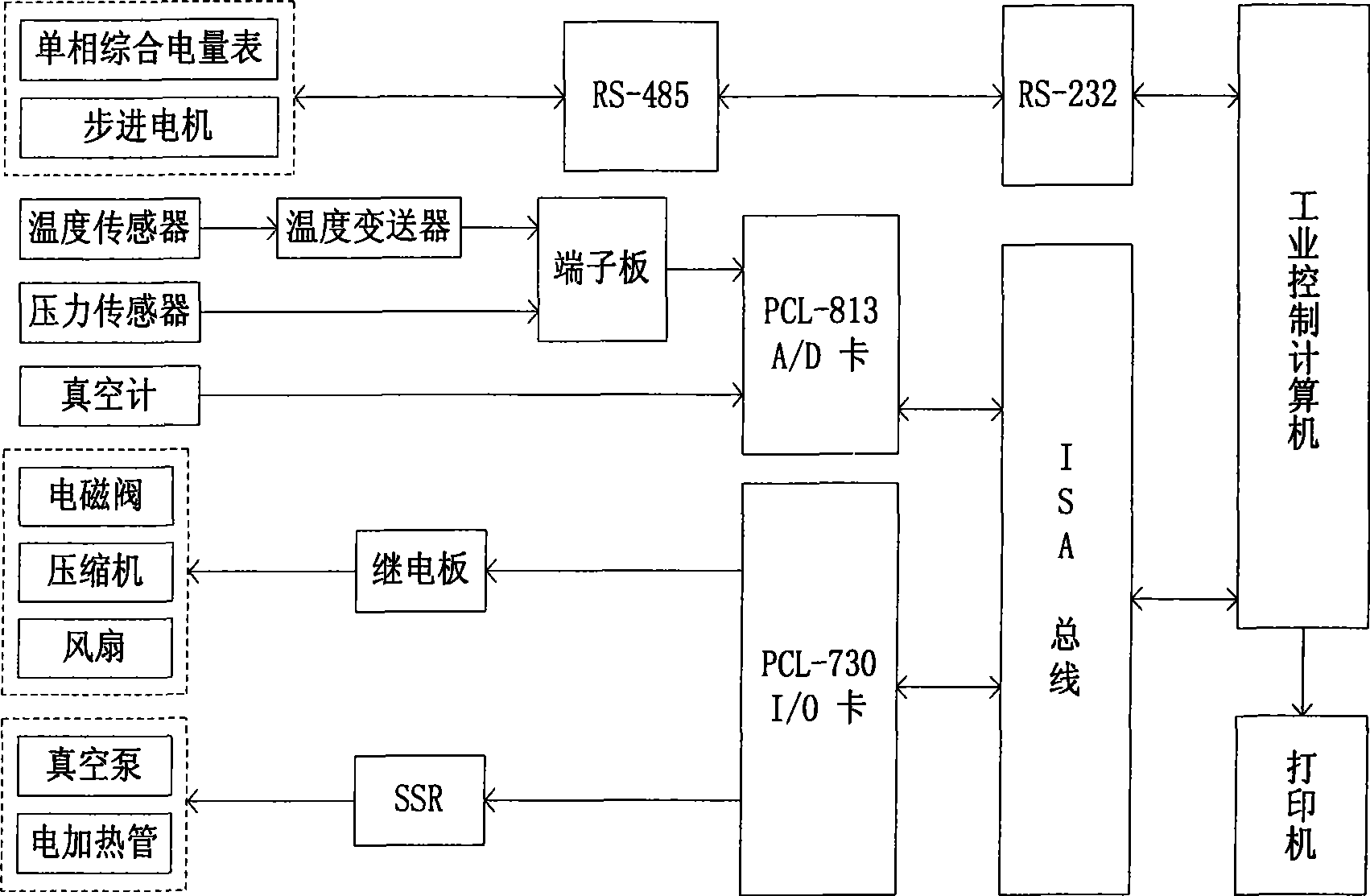

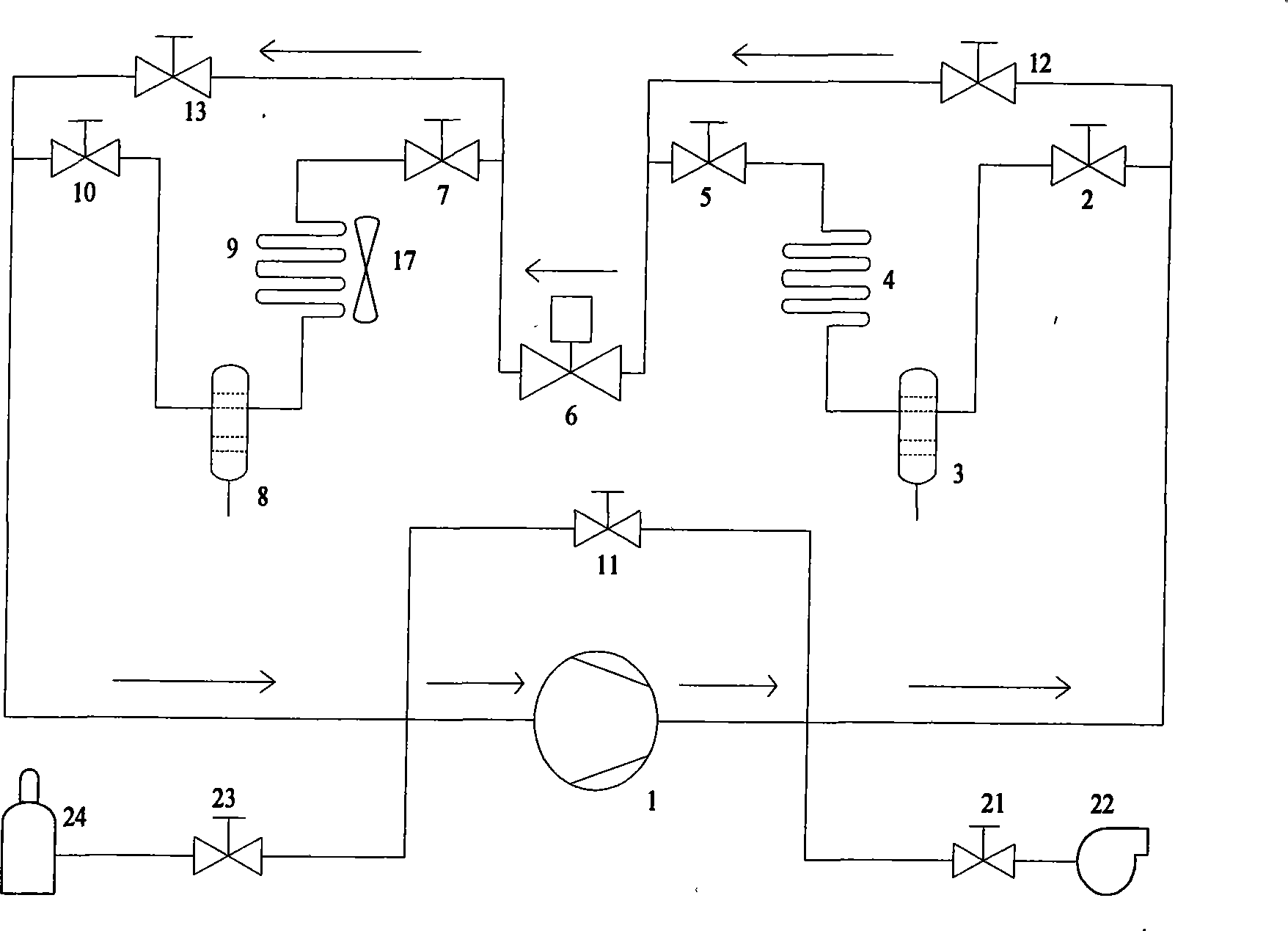

[0020] see figure 1 A device for measuring the oil circulation volume of a small refrigeration compressor, including a substituting refrigeration subsystem for making the compressor work under specific working conditions and a measurement and control subsystem for controlling the working conditions of the substituting refrigeration subsystem and measuring the oil circulation volume, The alternative refrigeration subsystem includes a refrigeration operation unit, a refrigerant adding unit, and a vacuum pumping unit. The alternative refrigeration subsystem adopts a two-stage heating oil separation structure, in which the refrigeration operation unit: the exhaust port and the suction port of the compressor 1 under test respectively pass through Exhaust interface, suction interface and exhaust oil inlet valve 2, exhaust oil-gas separator 3, condensation pipe 4, exhaust oil outlet valve 5, expansion valve 6, suction oil inlet valve 7, evaporation pipe 9, suction The oil-gas separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com