Oil layer electrical heating oil extracting device and using method thereof

An oil production device and electric heating technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of cold damage to the oil layer, large area occupied by the heating furnace, thickening of crude oil in the oil layer, etc., and achieve easy The effect of automation, convenient adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

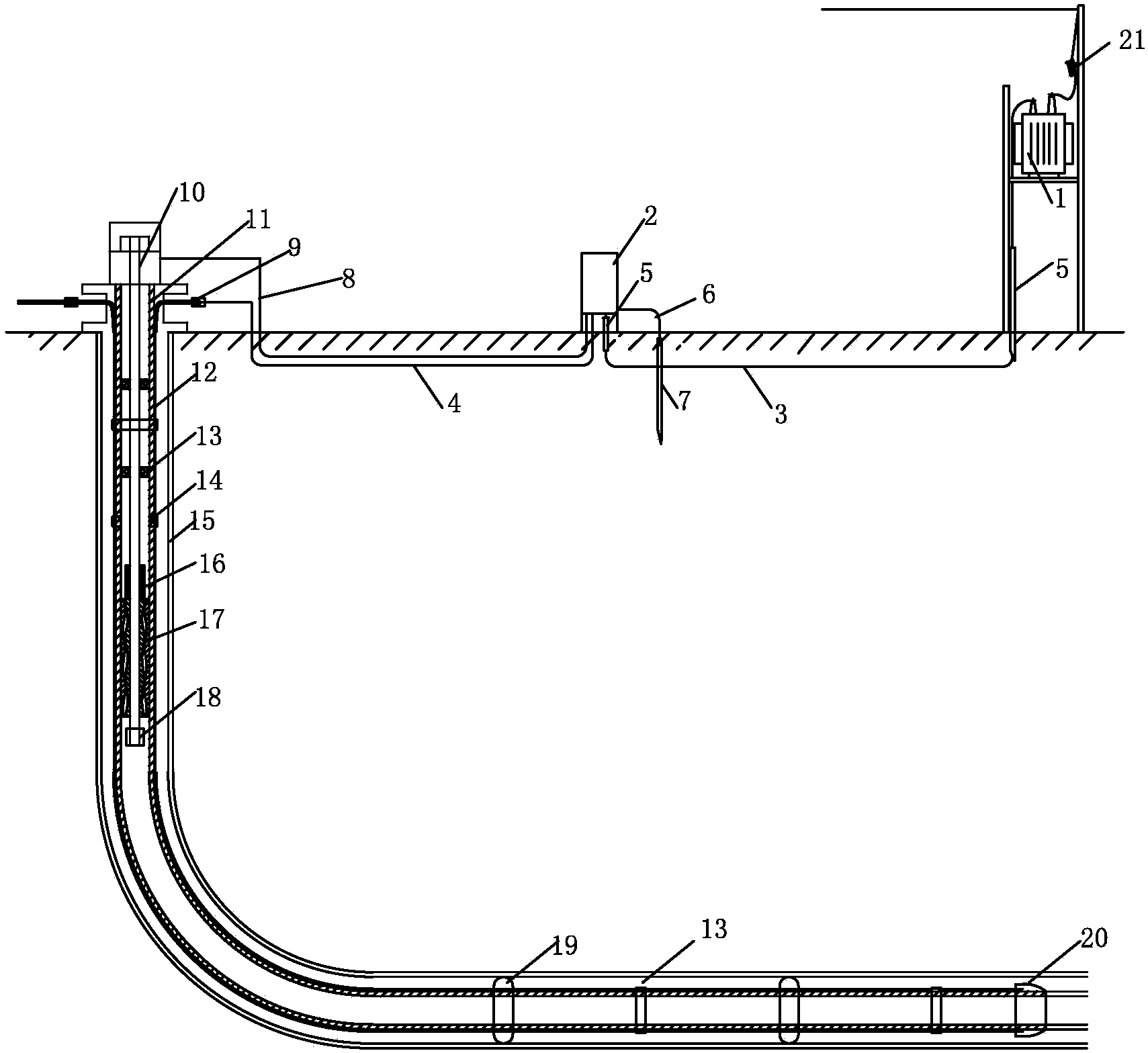

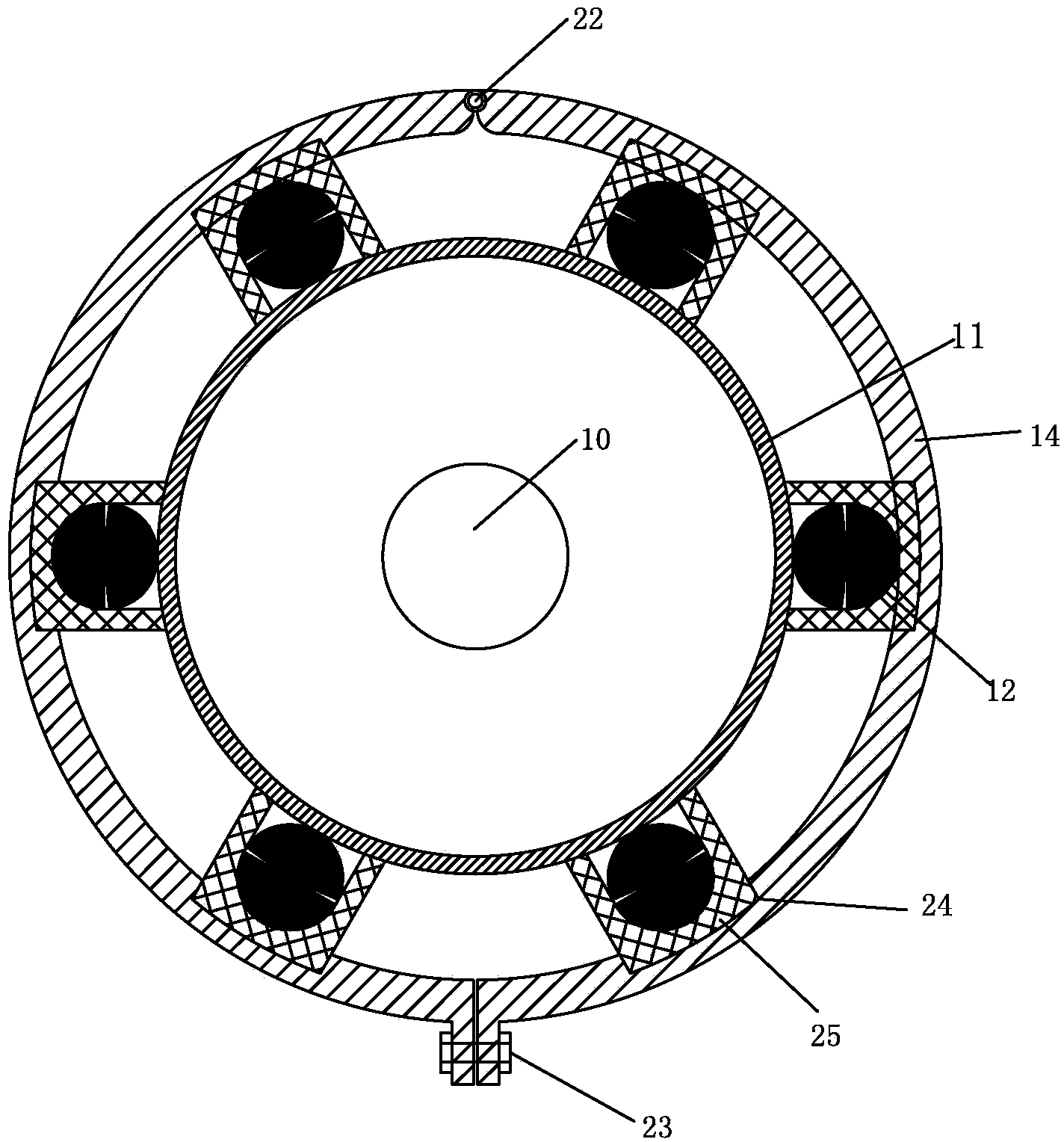

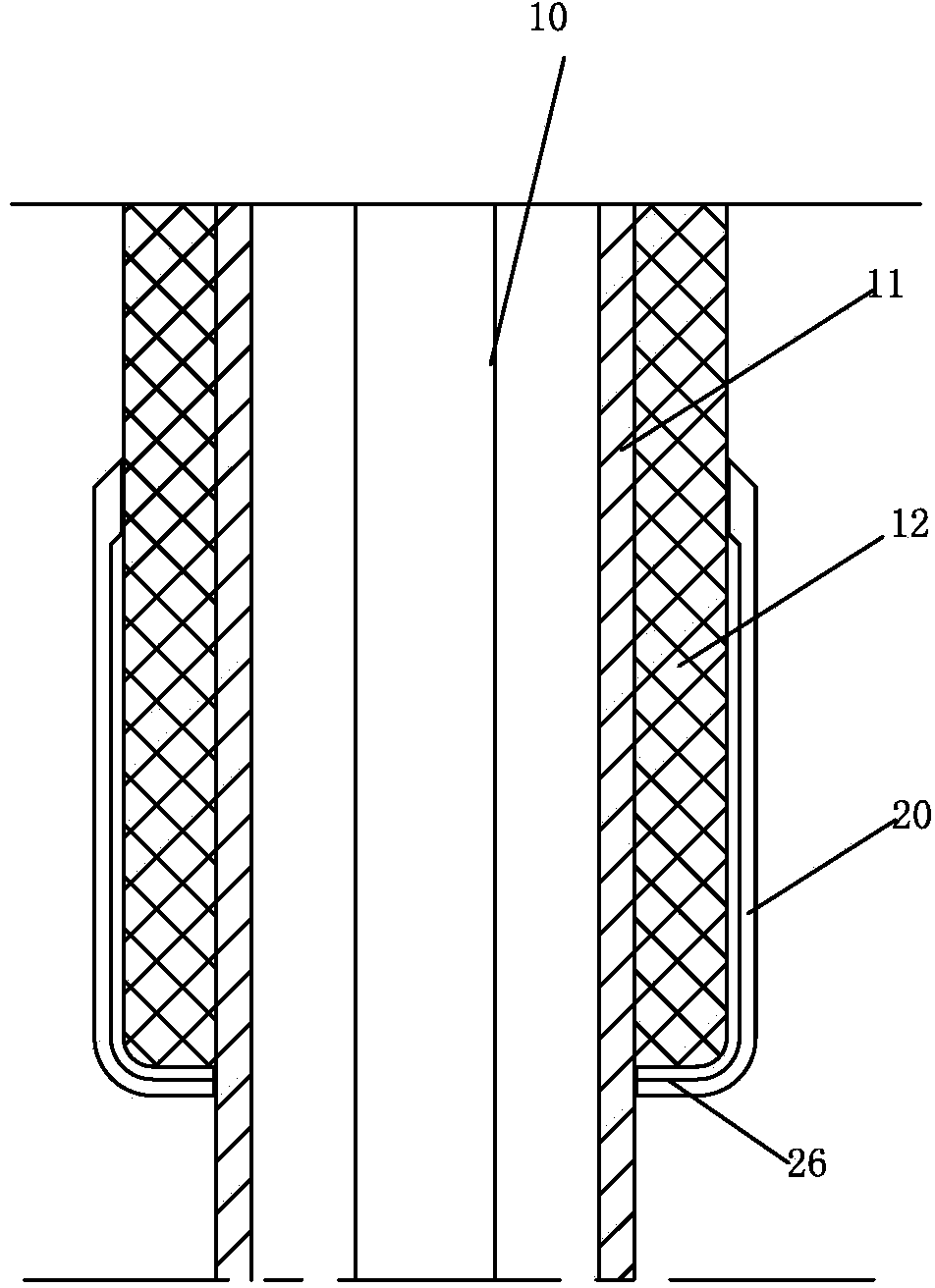

[0020] Such as figure 1 As shown, the oil layer electric heating oil recovery device in the present invention includes a special transformer 1, a control cabinet 2, an input cable 3 for connecting the special transformer 1 and the control cabinet 2, an output cable 4, a hollow screw pump 17, an oil pipe 11, and A plurality of steel-armored heating cables 12 that are closely attached to the outer wall of the oil pipe 11 are connected to form a closed circuit by heating cable clamps 20 at the ends where the steel-armored heating cables 12 extend into the oil pumping well. in:

[0021] The special transformer 1 converts the external power supply into the voltage required by the steel armored heating cable 12. A main switch 21 is installed at the front end of the special transformer. The special transformer 1 communicates with the control cabinet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com