Broken yarn protection system of warp knitting machine

A technology for thread breakage protection and warp knitting machines, which is applied in textiles, papermaking, knitting, etc., can solve the problems of not working seriously, warp knitting machines continuing to work, unfavorable for operators to continue working, warp knitting machines malfunctioning, etc., to achieve The effect of simple structure, high alignment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

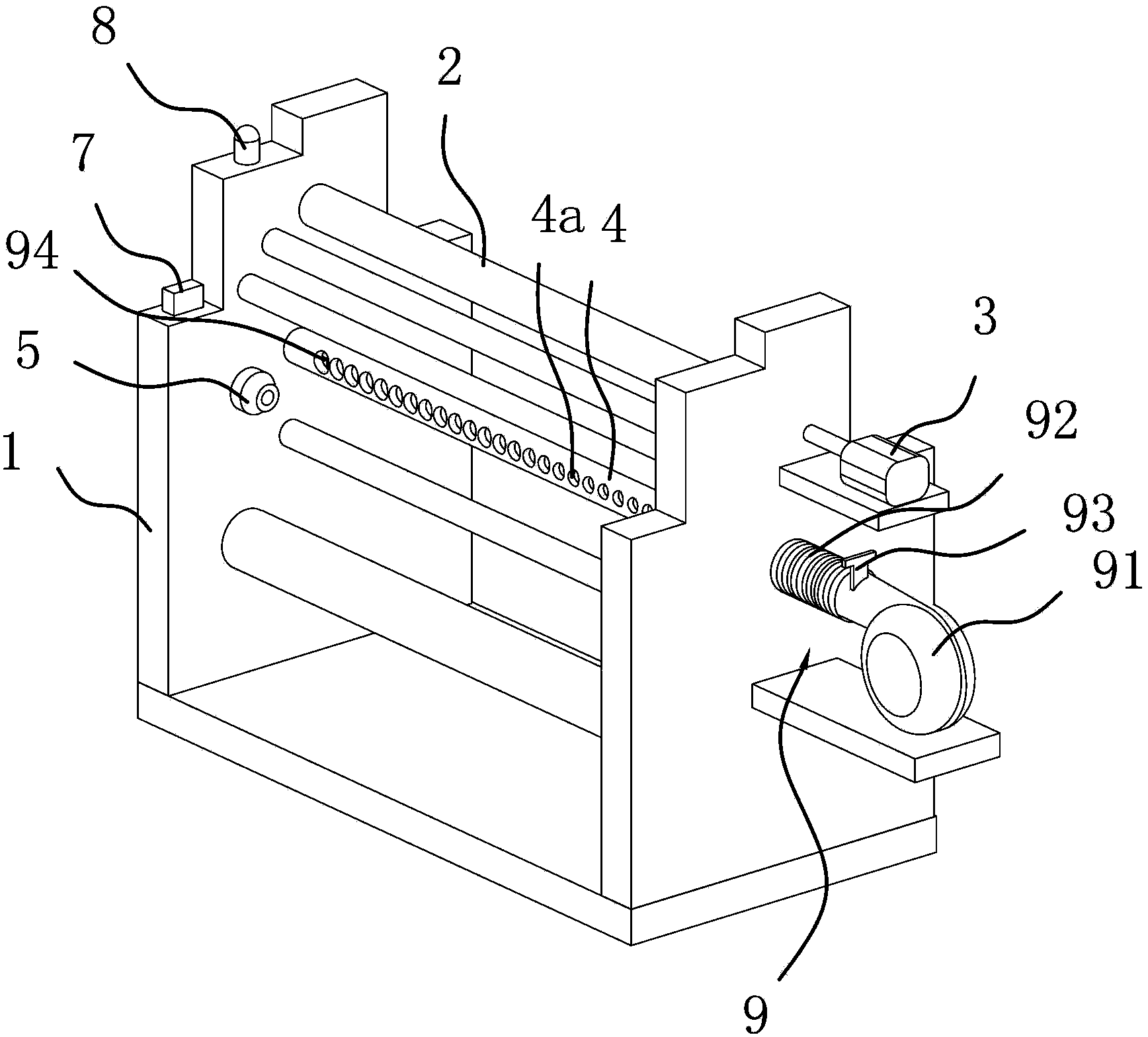

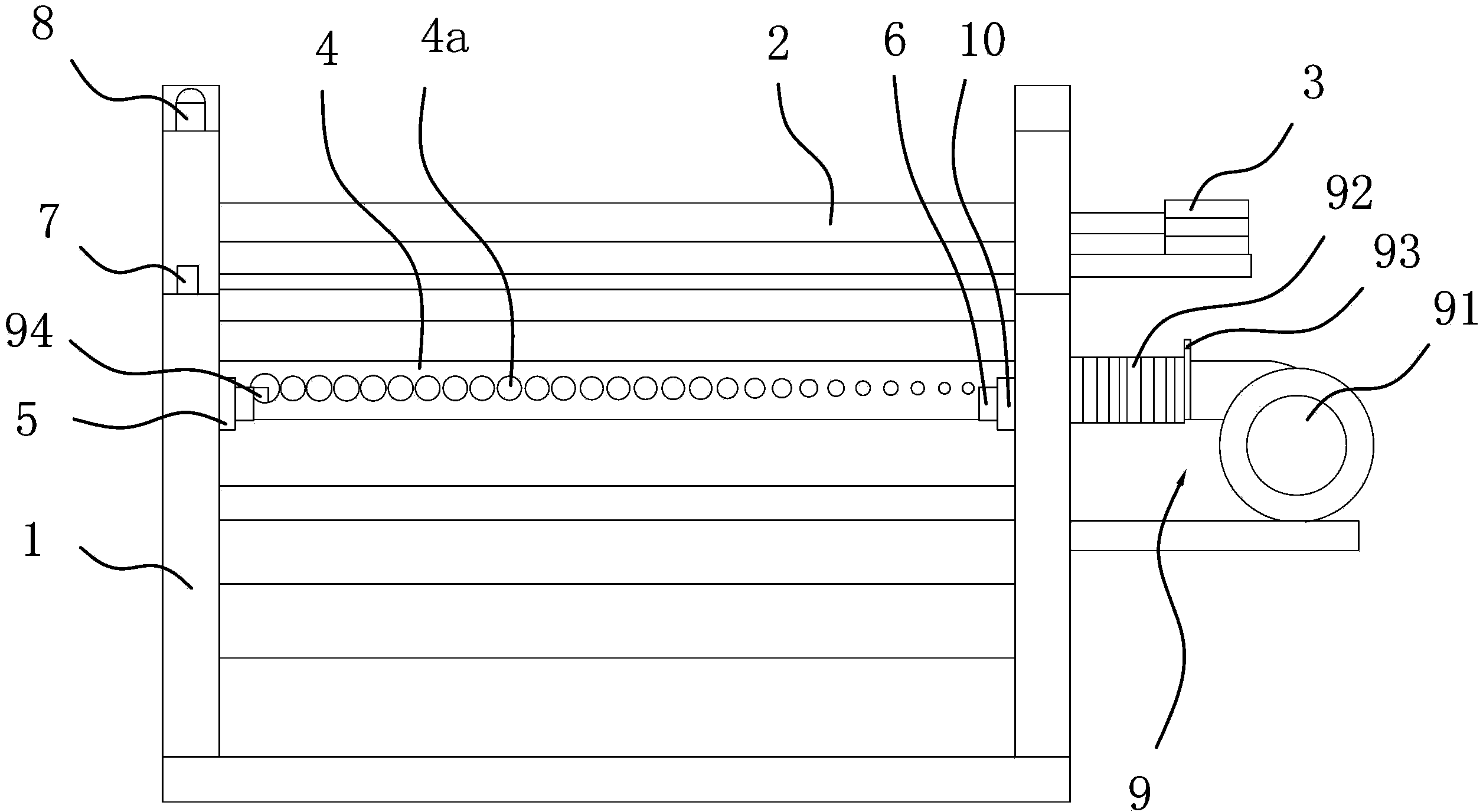

[0032] Such as figure 1 Shown, a kind of warp knitting machine, comprises frame 1 and is arranged on frame 1 and is used for conveying some wire feeding rollers 2 of yarn, and wire feeding roller 2 is driven its rotation by driving motor 3, and driving motor 3 Fixed on one side of the frame 1 through the fixed plate; as figure 2 As shown, a wire breakage protection system for a warp knitting machine includes an air outlet pipe 4 fixed on a frame 1 and parallel to the wire feeding roller 2, an infrared transmitter 5 and an infrared receiver 6, and the infrared transmitter 5 Fixed on one end of the frame 1, the infrared receiver 6 is fixed on the other end of the frame 1, and the infrared emitter 5 faces the infrared receiver 6, the infrared emitter 5 and the infrared receiver 6 form a sensing line, and the sensing line is in the On one side of the yarn, the infrared receiver 6 is also connected to a control mechanism that can stop the drive motor 3; Several air outlet holes ...

Embodiment 2

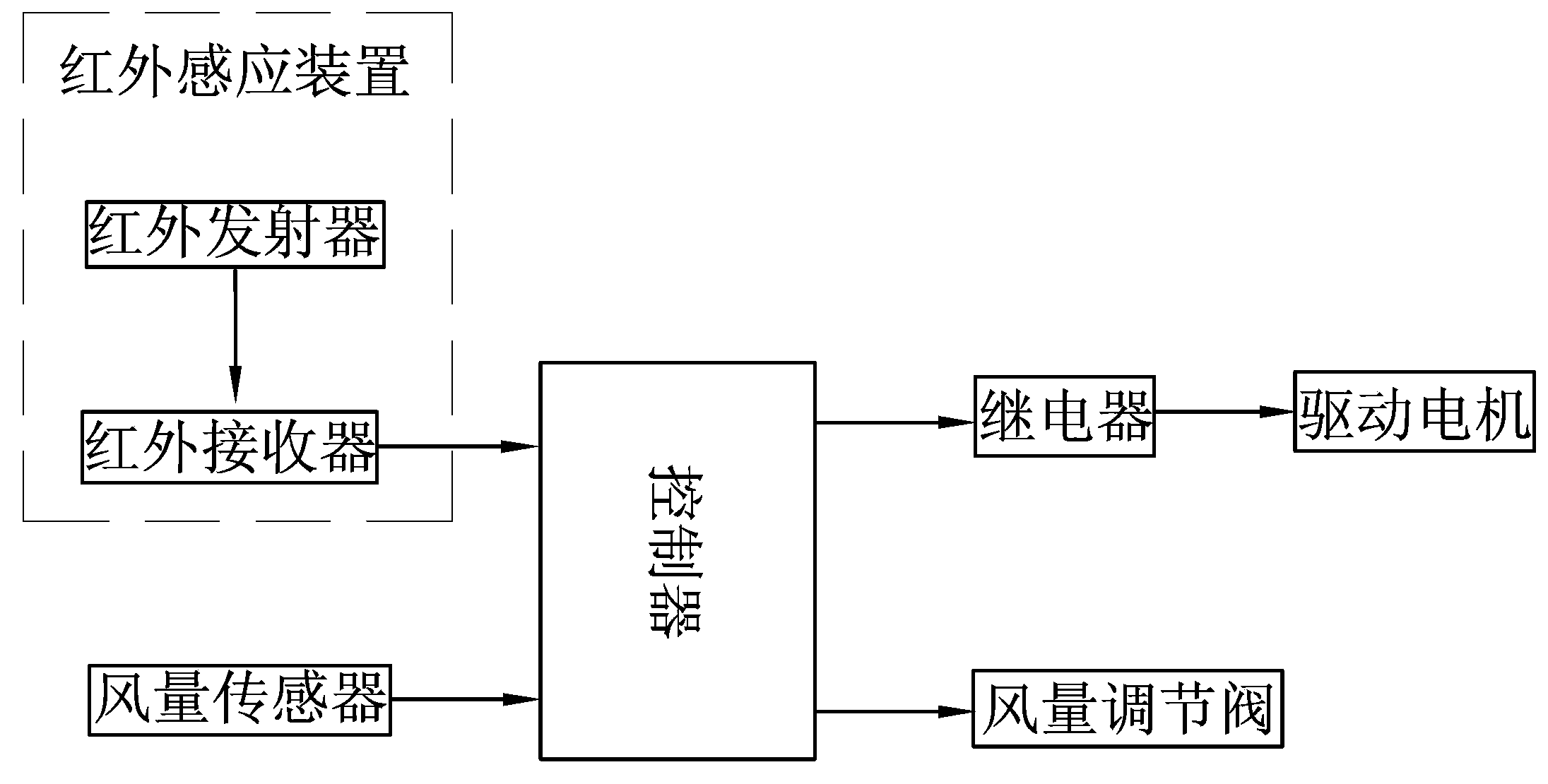

[0037] The structure and principle of the present embodiment are basically the same as those of the first embodiment, the difference being: in the first embodiment, the control mechanism includes a PLC programmable controller and an alarm bell; and in the second embodiment, such as image 3 As shown, the control mechanism includes a controller and a buzzer, the controller and the buzzer are fixed on the frame, the input end of the controller is connected with the infrared receiver, the output end of the controller is connected with a relay, and the relay is connected with the drive motor Connection, the output terminal of the controller is also connected with the buzzer through the line. Specifically, the relay includes a normally open switch and a coil, the output terminal of the controller is connected to one end of the normally open switch, the other end of the normally open switch is connected to the drive motor, the output terminal of the controller is connected to the coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com