Heat sink and centrifugal fan applied by same

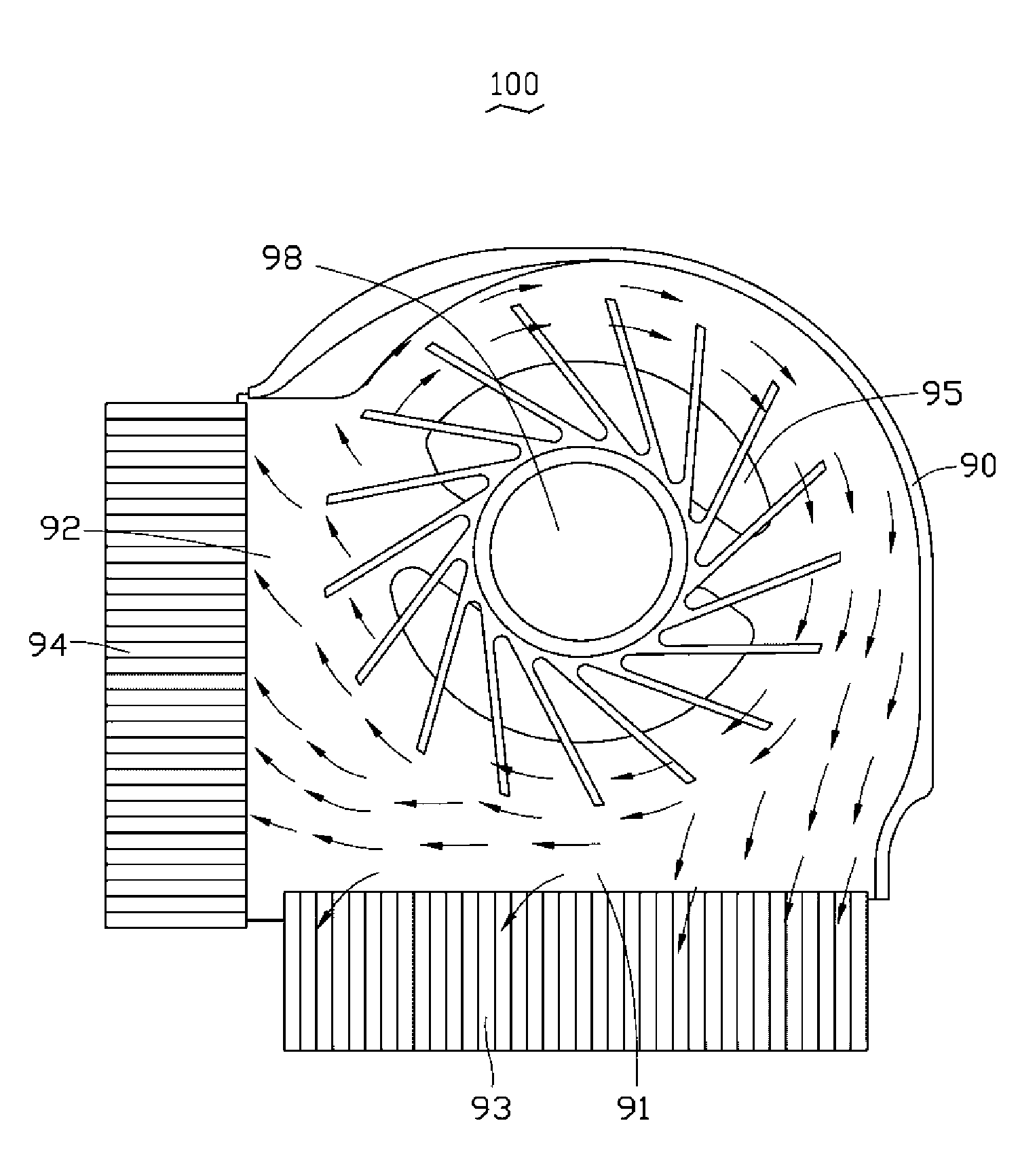

A centrifugal fan and heat dissipation device technology, applied to the parts of the pumping device for elastic fluid, cooling/ventilation/heating transformation, instruments, etc., can solve the problem of affecting the heat dissipation performance of the heat dissipation module 100, reducing the utilization rate of heat sinks, Uneven distribution of air volume and other issues, to achieve the effect of improving heat dissipation performance, improving utilization rate, and evenly receiving wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

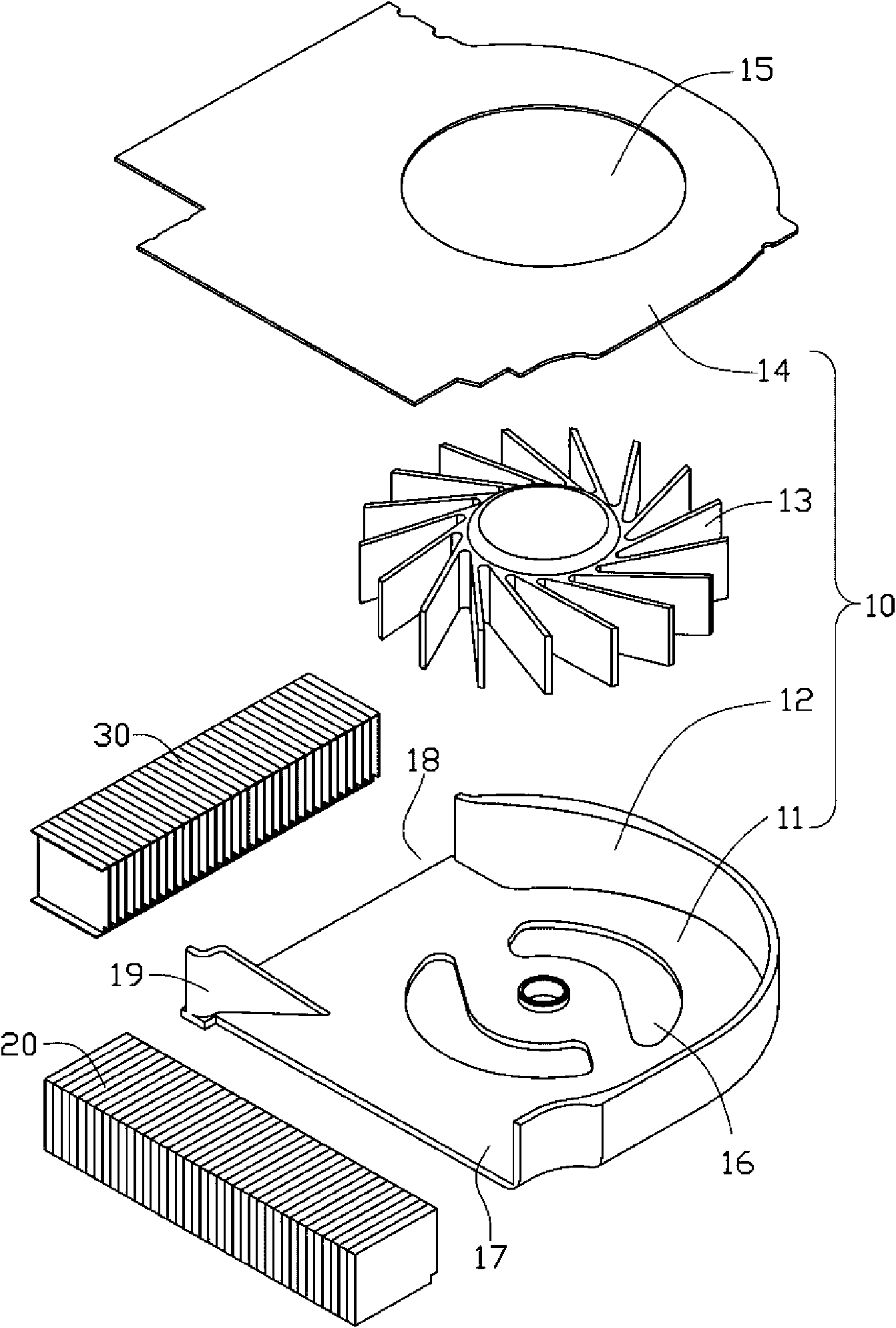

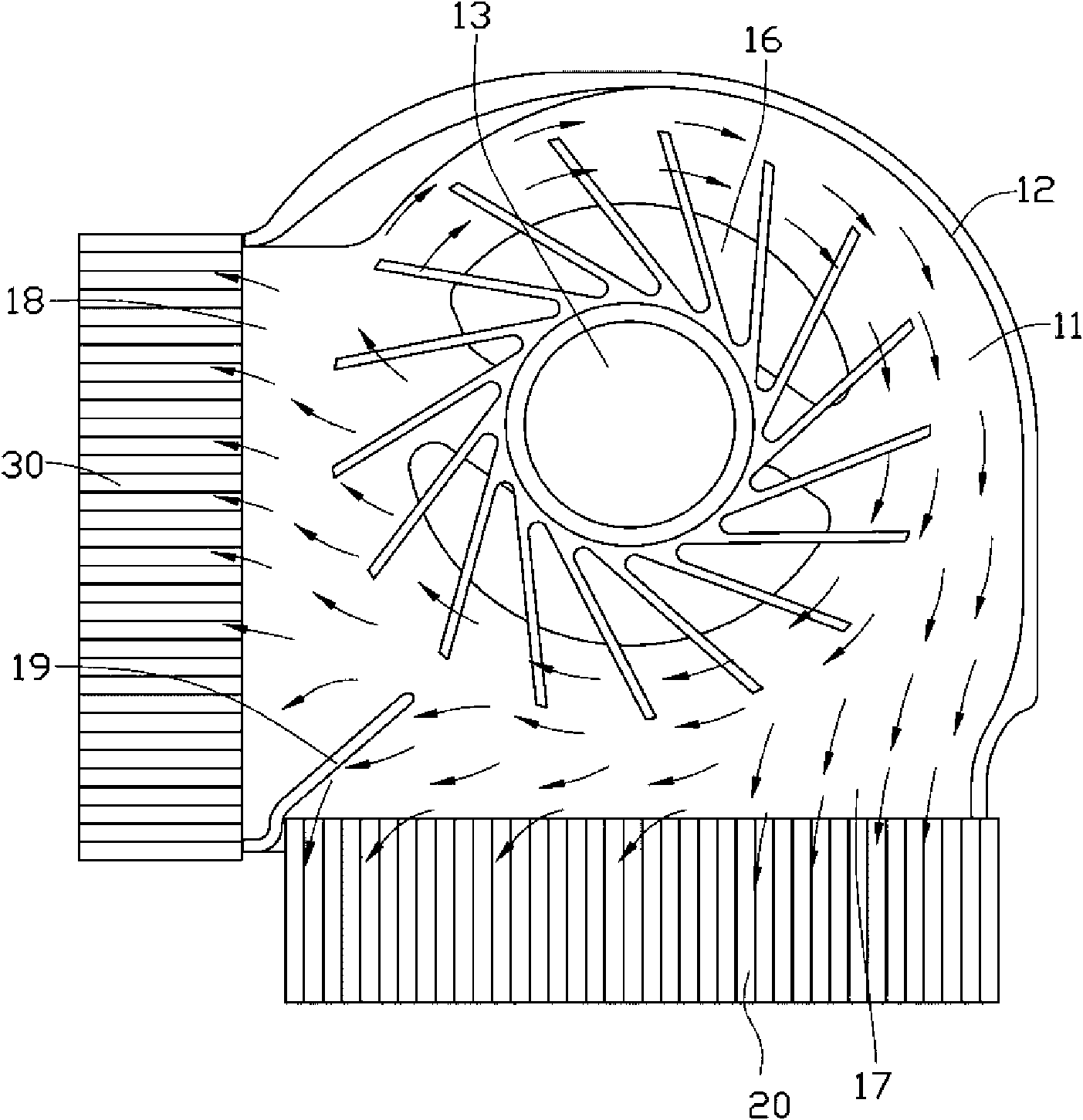

[0013] See figure 2 and image 3 The heat dissipation device includes a centrifugal fan 10, a first fin group 20 and a second fin group 30. The centrifugal fan 10 includes an impeller 13, a top plate 14, a bottom plate 11 opposite to the top plate 14, and a spiral side wall 12 arranged between the top plate 14 and the bottom plate 11.

[0014] The top plate 14, the bottom plate 11 and the side walls 12 of the centrifugal fan 10 are enclosed to form a fan frame, and an accommodating space is formed in the fan frame, and the impeller 13 is accommodated in the accommodating space. The top plate 14 is provided with a first air inlet 15 and the bottom plate 11 is provided with a second air inlet 16, the side wall 12 extends vertically upward from the periphery of the bottom plate 11 and surrounds the bottom plate 11, and the side wall 12 is provided with a first air outlet 17 and A second air outlet 18 adjacent to the first air outlet 17. The first and second air outlets 17, 18 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com