Electrolytic manganese dioxide cyclone separator

A technology of electrolytic manganese dioxide and cyclone separator, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc. The effect of good thermal insulation, improved structure, strong rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

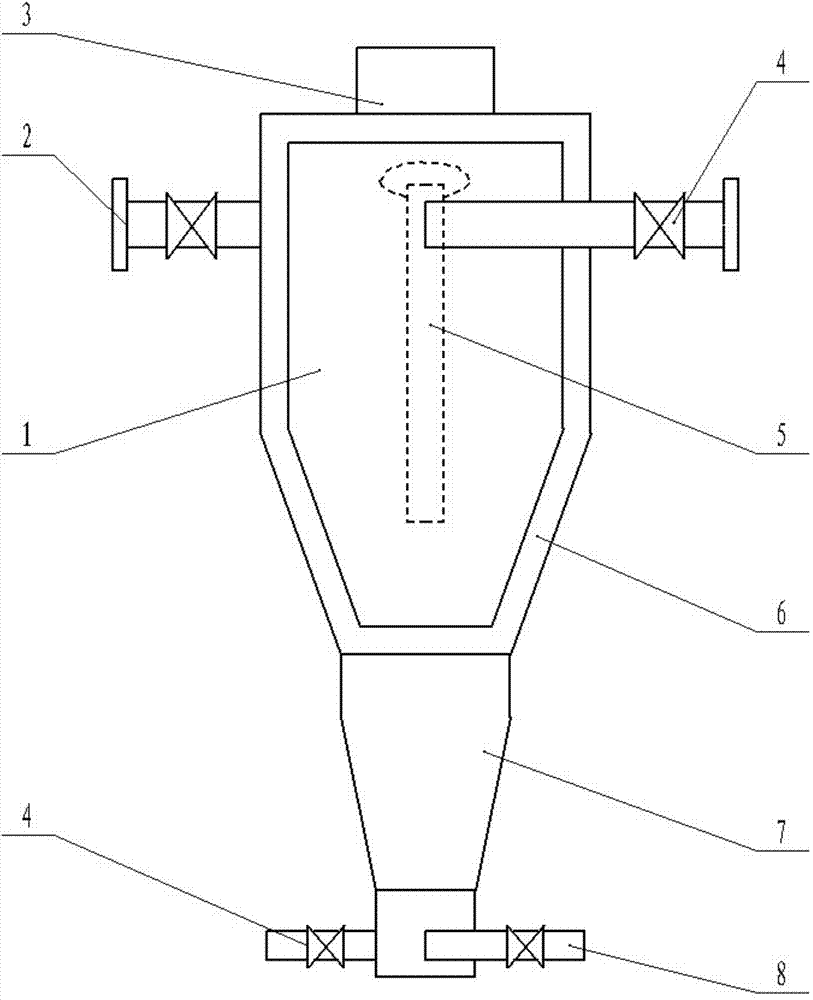

[0023] An electrolytic manganese dioxide cyclone, comprising a cylinder body 1, an air inlet pipe A2 and an air outlet pipe 3, the upper part of the cylinder body 1 is a cylinder, the lower part is a cone, and a cylinder at the upper end of the cylinder body 1 An air inlet pipe A2 is arranged at the tangent of the outer wall, and the said air inlet pipe A2 is two, and the two air inlet pipes A2 are on the same horizontal plane and are parallel to each other. An air outlet pipe 3 is arranged at the upper end cap of the cylinder body 1, and a vortex stabilization pipe 5 is arranged directly below the air outlet pipe 3 in the cylinder body 1, and the diameter of the vortex stabilization pipe 5 is smaller than the diameter of the air inlet pipe A2 . A cyclone joint 7 is provided at the lower end of the cylindrical body 1 , and an air inlet pipe B8 is arranged on the cyclone joint 7 . There are two air inlet pipes B8, and the two air inlet pipes B8 are on the same horizontal plane...

Embodiment 2

[0026] An electrolytic manganese dioxide cyclone, comprising a cylinder body 1, an air inlet pipe A2 and an air outlet pipe 3, the upper part of the cylinder body 1 is a cylinder, the lower part is a cone, and a cylinder at the upper end of the cylinder body 1 The air inlet pipe A2 is set at the tangent of the outer wall. The air inlet pipe A2 is two, and the two air inlet pipes A2 are on the same horizontal plane and are parallel to each other. The air outlet pipe 3 is set at the upper end cover of the cylinder 1 , a vortex stabilization tube 5 is arranged directly below the air outlet pipe 3 in the cylindrical body 1, and the diameter of the vortex stabilization tube 5 is smaller than the diameter of the air inlet pipe A2. The outer layer of the cylinder body 1 is provided with a vacuum chamber 6 , and a vacuum valve is arranged on the vacuum chamber 6 . A cyclone joint 7 is arranged at the lower end of the cylinder body 1 ; an air inlet pipe B8 is arranged on the cyclone jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com