Static aerobic fermentation reactor for domestic garbage

A technology of aerobic fermentation and domestic waste, applied in the direction of climate change adaptation, organic fertilizer, etc., can solve the problems of high cost and maintenance cost of replacing the pipeline system, affecting the normal application of the reactor, and difficult dredging of the pipeline by wind, so as to save material costs and manpower costs, easy post-maintenance and maintenance, simple and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] With reference to the drawings and preferred embodiments, the specific embodiments, structures, and features provided in accordance with the present invention are described in detail as follows:

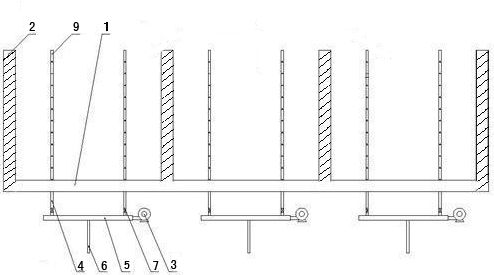

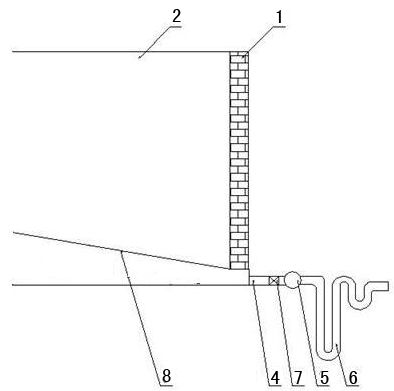

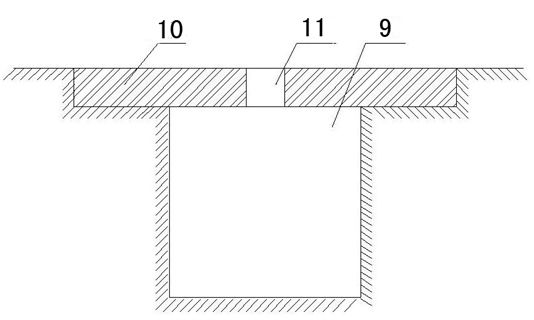

[0022] Such as Figure 1-Figure 3 As shown, a domestic garbage static aerobic fermentation reactor includes a fermentation bin, a drainage ventilation pipe 4, and a blower; the fermentation bin is a three-format brick-concrete structure, consisting of a main wall 1 and evenly spaced The side wall 2 is enclosed to form the side walls of the three-cell silo body side by side; the reactor corresponds to the main wall 1 of the three-cell silo body, and the external ground is connected with a drainage ventilation pipe 4, a drainage ventilation main pipe 5 and a U-shaped drainage pipe 6; The overall structure of the reactor is inclined from the floor of the fermentation silo to the outlet of the U-shaped drainage pipe 6; the floor 8 of each fermentation silo is parallel to the side wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com