Hatch Cover For A Covered Railroad Car Having Removable Closure and Screen Member

a technology for railroad cars and hatch covers, which is applied to railway roofs, railway components, transportation and packaging, etc., can solve the problems of reducing the efficiency of vacuum unloading process and risking damage to the car structure, and achieve the effect of facilitating the opening and closing of the hatch cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

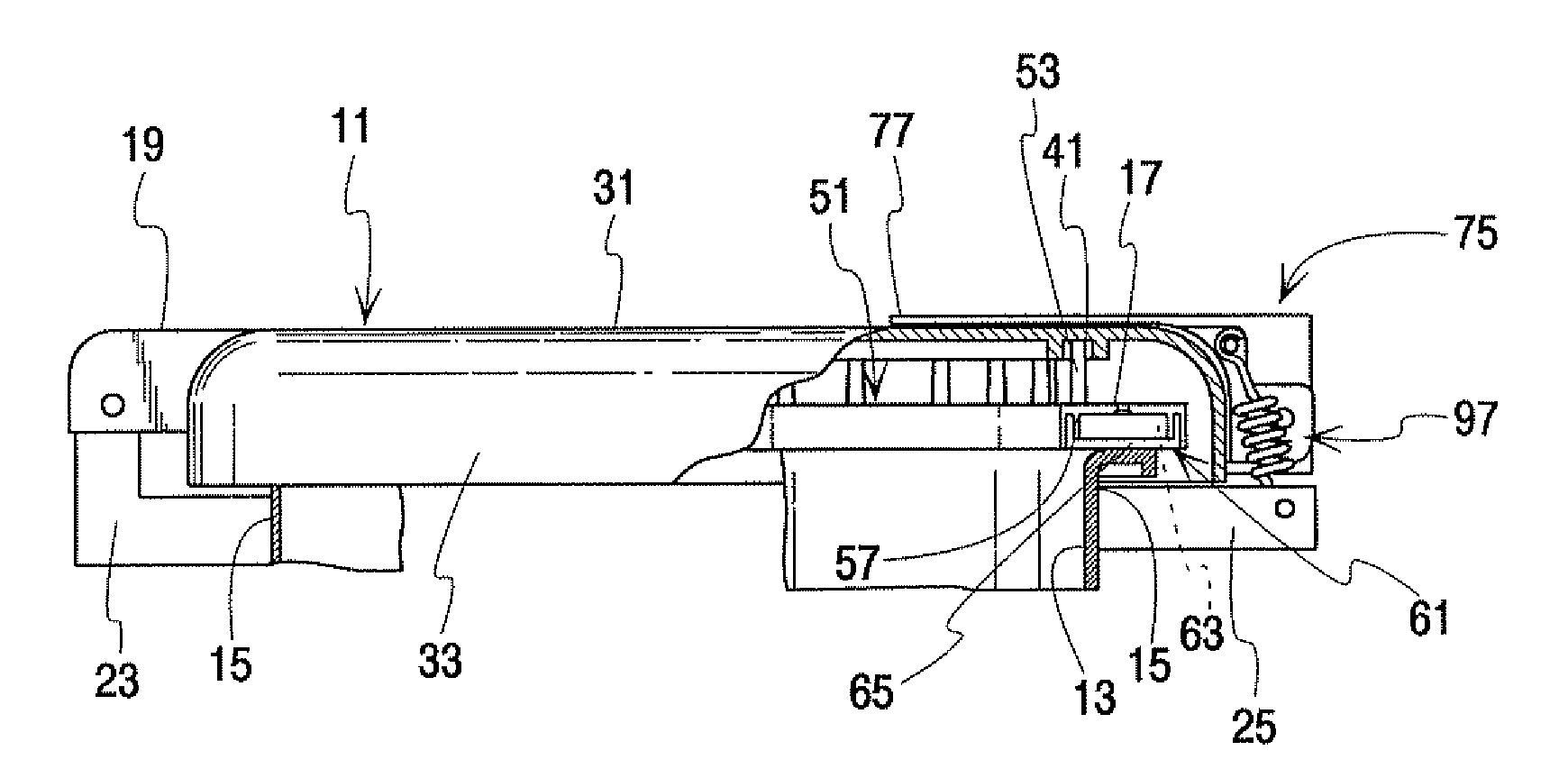

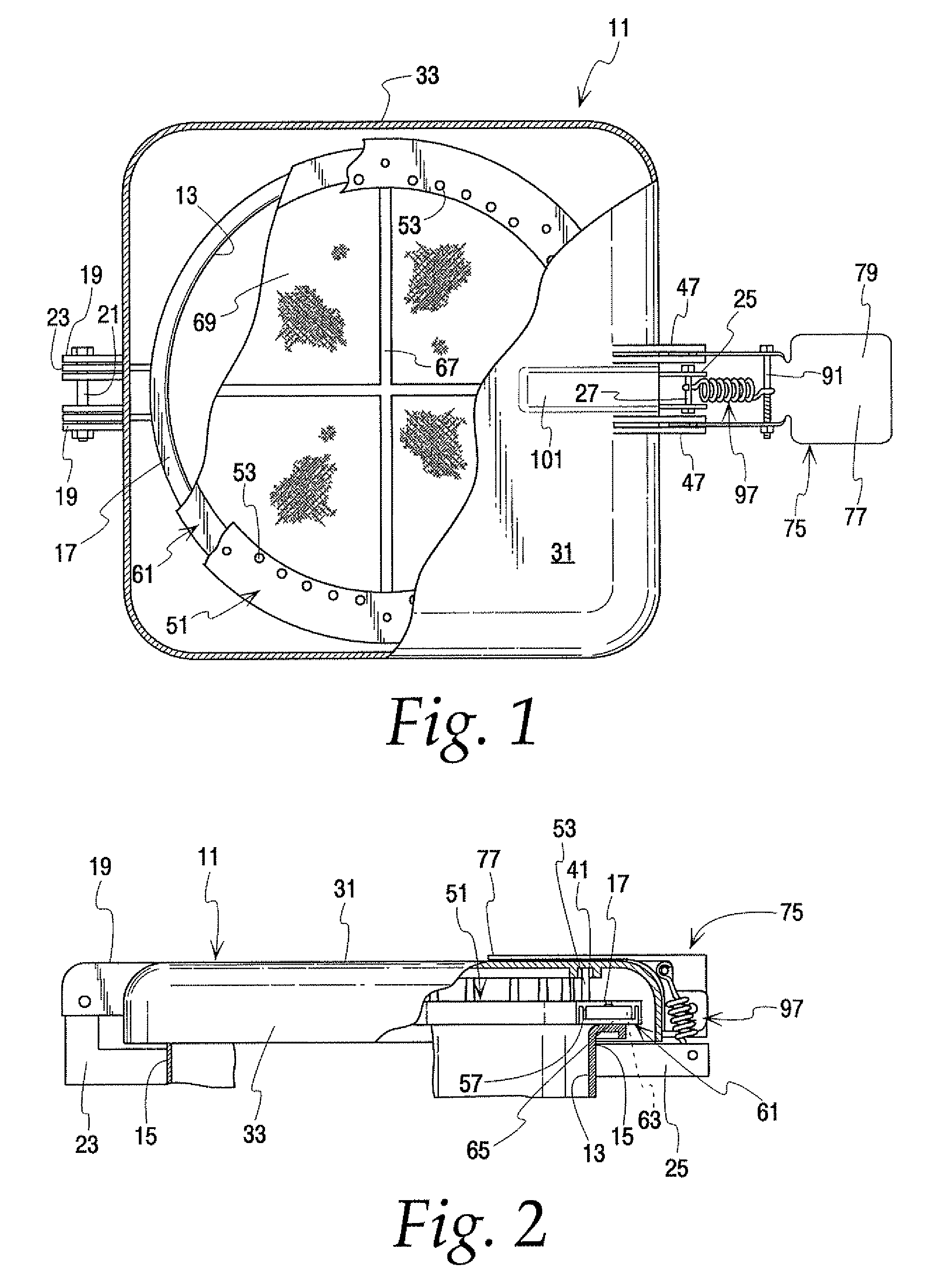

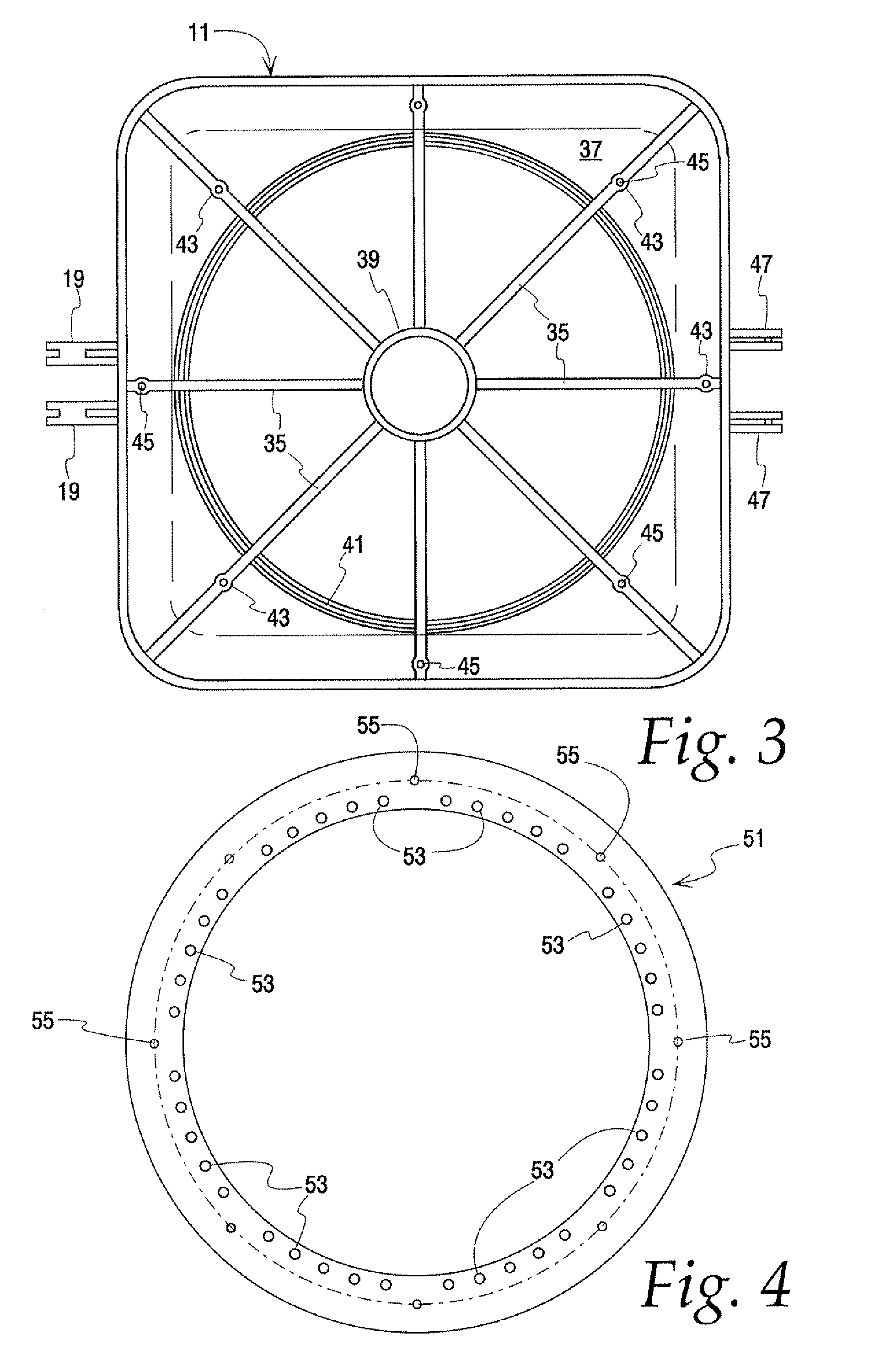

[0022]FIG. 1 of the drawings shows a hatch cover 11 of this invention which can be used to close or uncover an opening 13 which is surrounded by a coaming 15 of a hopper compartment such as the type found on railroad hopper cars. As is conventional, an annular lip 17 is formed on the top of the coaming. While the coaming shown in the drawings has a turned over flange or annular lip 17, not all coamings include such an annular lip. The hatch cover of this invention may be used with convention coamings of all shapes and types. Also shown in FIG. 1 are brackets 19 which attach to the hatch cover 11 and receive a pivot pin 21. As shown in FIG. 2, additional brackets 23 attached to the coaming 15 also engage and support the pivot pin 21. Brackets 25 which are most clearly shown in FIG. 2 also attach to the coaming 15 and support a spring anchor pin 27 which can be best seen in FIGS. 9 and 10 of the drawings.

[0023]As is most clearly shown in FIGS. 1, 2, and 3 of the drawings, the hatch co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com