Modularized railway vehicle body

A rail vehicle and modular technology, applied in the field of rail vehicles, can solve the problems of not providing window height, various tooling, and poor appearance visibility, so as to promote unified and modular design, reduce life cycle costs, and improve The effect of product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

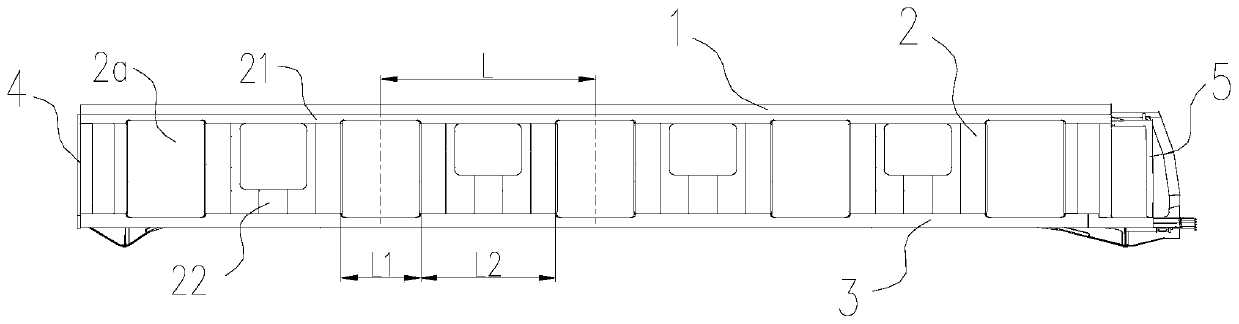

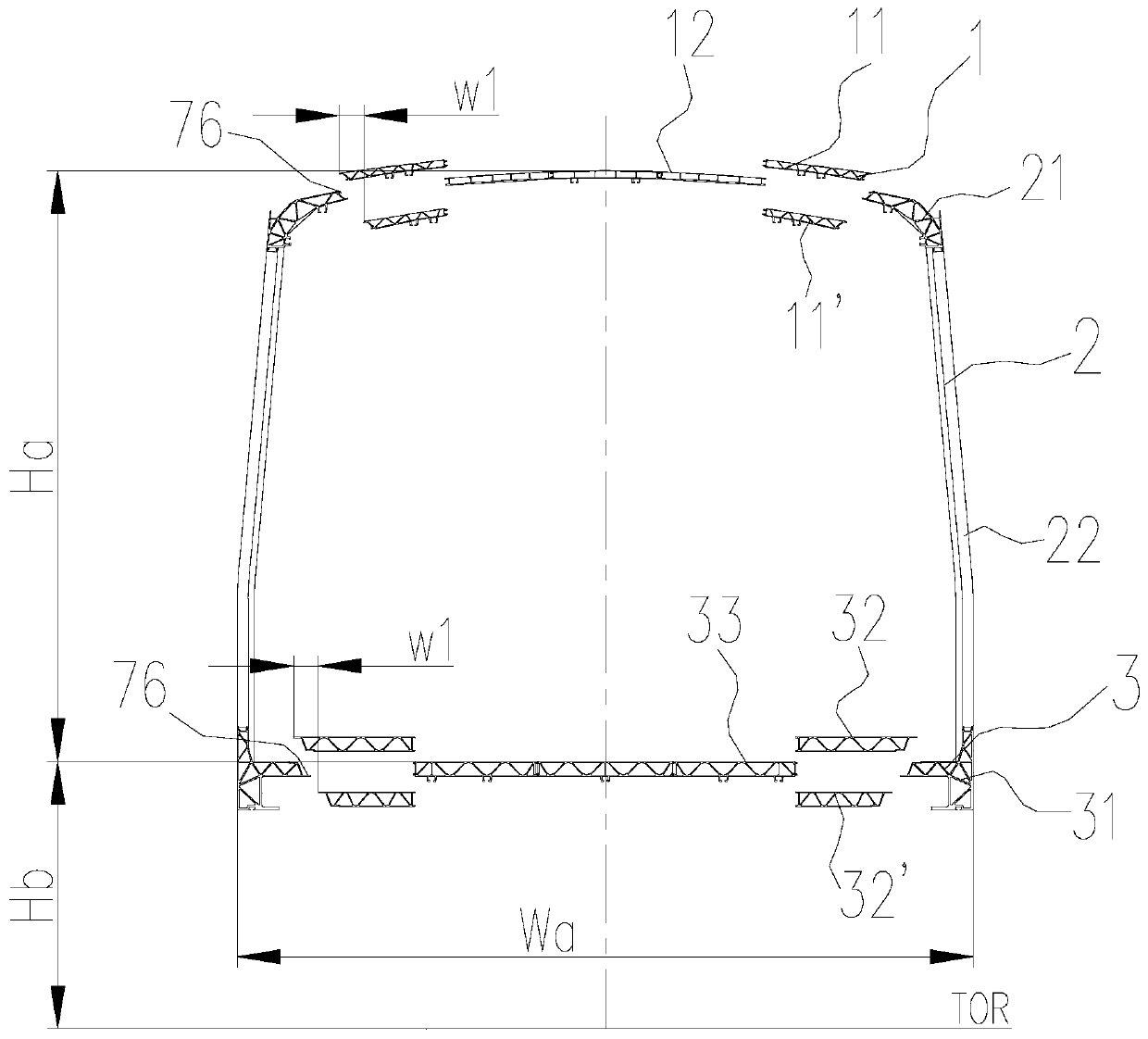

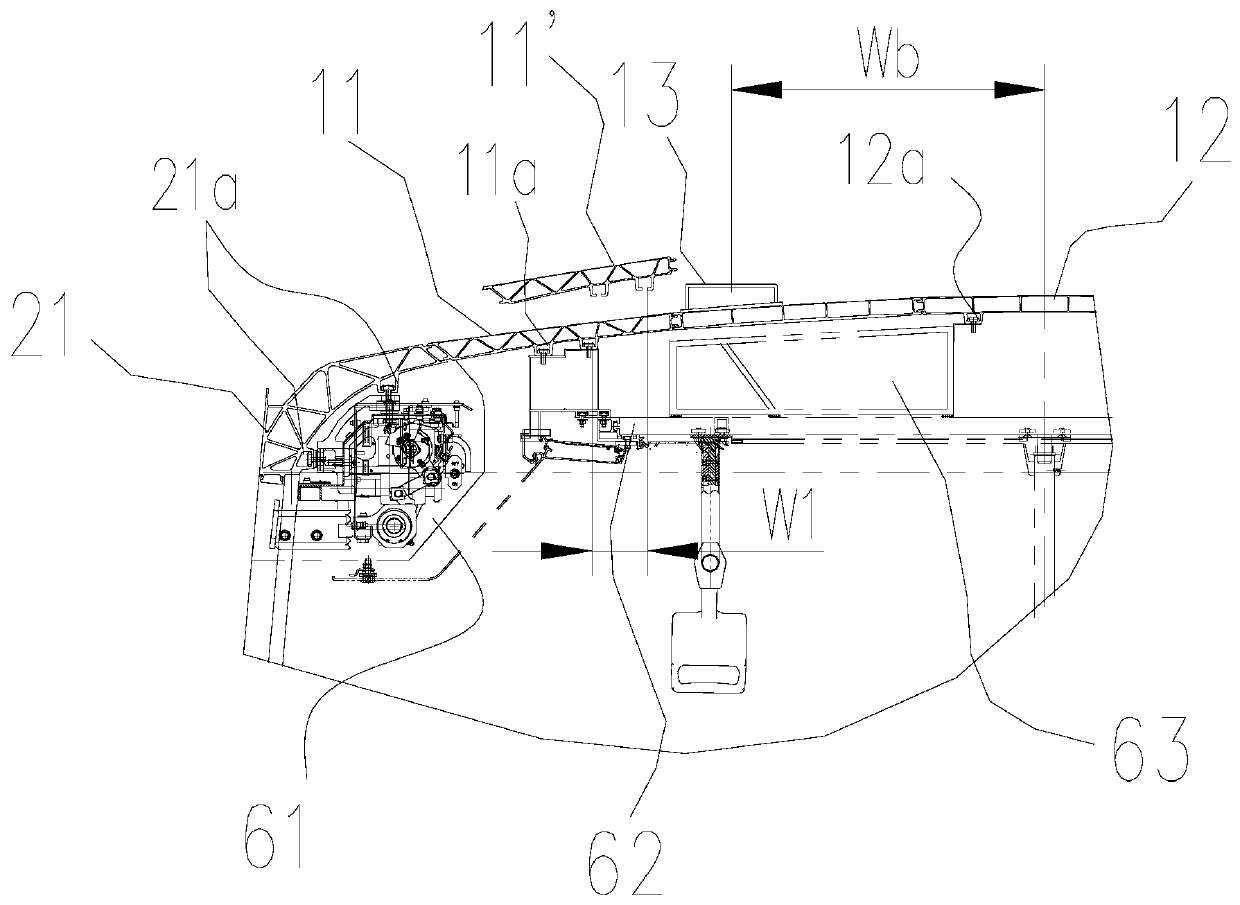

[0072] A modular subway (take the subway train body as an example) car body, such as figure 1 Shown: the vehicle body comprises a roof 1, a side wall 2, an underframe 3, an end wall 4 and a driver's cab framework 5. The roof 1 adopts a long micro-arc roof structure. The side wall 2 adopts an integral structure, and is composed of a side wall top profile 21 with a long upper part and a block side wall unit 22 . For the domestic A / B type subway car, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com