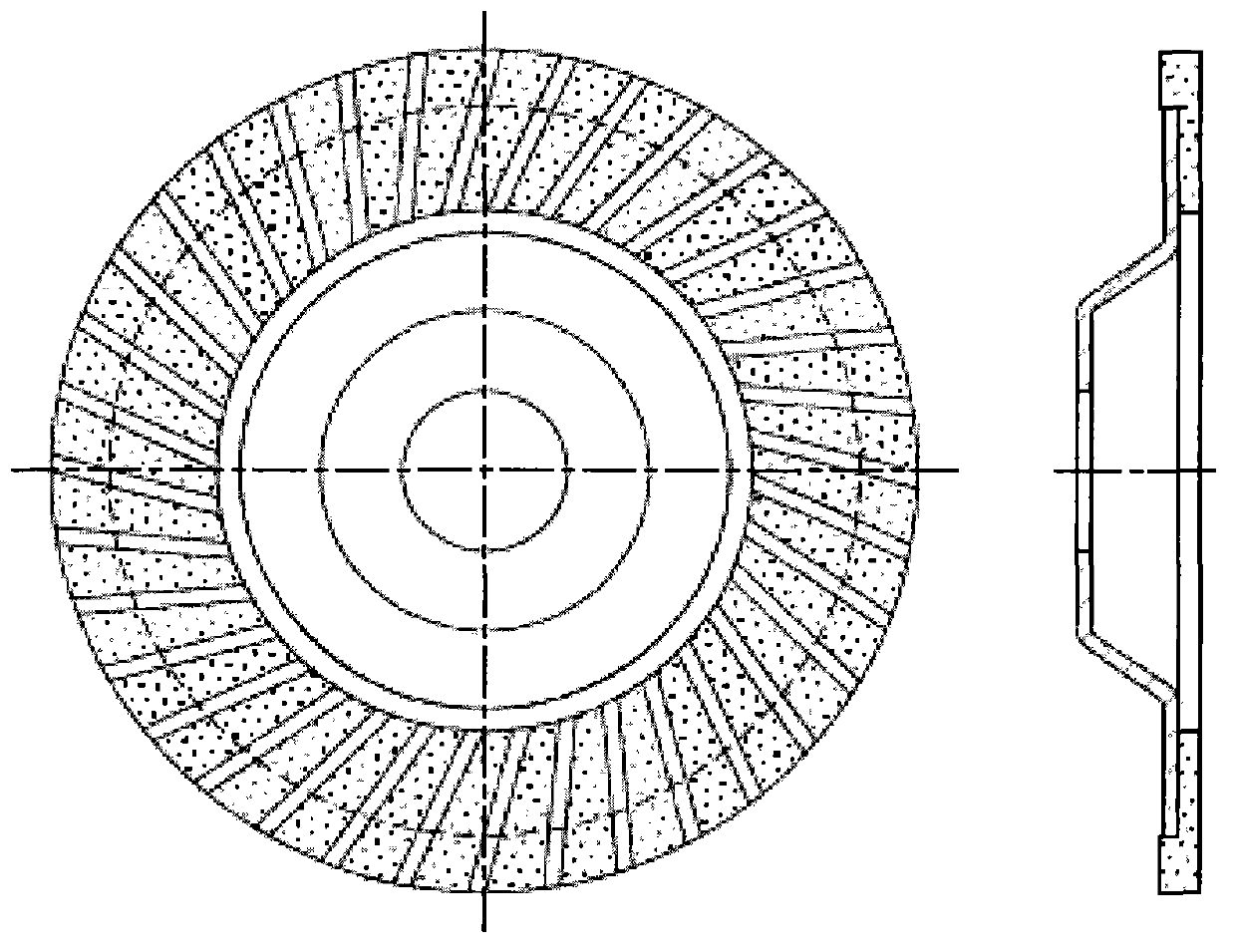

Diamond cutting grinding piece

A technology of diamond and cutting and grinding discs, applied in the field of diamond cutting and grinding discs, can solve the problems of independent cutting and grinding performance, and achieve the effects of safe and reliable performance, good product sharpness, and guaranteed connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The diamond cutting disc is prepared by the above method, and the metal bond is a mixed elemental powder, which is composed of 35wt% Cu, 35wt% Fe, 10wt% Ni, 5wt% Sn and 15wt% The composition of Co.

Embodiment 2

[0027] The diamond cutting disc is prepared by the above method, and the metal bond in the diamond cutting disc material is a pre-alloyed powder, and the pre-alloyed powder is obtained by conventional water atomization treatment, and the pre-alloyed powder It consists of the following components: 35wt% Cu, 35wt% Fe, 10wt% Ni, 5wt% Sn and 15wt% Co.

Embodiment 3

[0029] The diamond cutting disc is prepared by the above method, and the metal bond in the diamond cutting disc material is a pre-alloyed powder, and the pre-alloyed powder is obtained by conventional water atomization treatment, and the pre-alloyed powder It consists of the following components: 35wt% Cu, 38.8wt% Fe, 10wt% Ni, 5wt% Sn, 10wt% Co and 1.2wt% Ce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com