High-precision mechanical sharpening method for diamond cutter with high-efficiency and low-cost

A technology of diamond tools and processing methods, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., which can solve the problems of difficult preparation of diamond tools and difficulty in meeting precision requirements, and achieve the effects of low cost, high efficiency, and simple sharpening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment 1: This embodiment processes the diamond tool according to the following steps: 1. After the air vibration isolation pad is inflated, adjust the balance state of the sharpening machine to keep it level; Control the working surface finish of the grinding disc to ≤0.8, and then coat diamond abrasive grains with a maximum diameter of 0.1 μm; 3. Use a high-precision dynamic balancer to perform fine dynamic balance on the spindle system of the grinding machine at a speed of 2800r / min, and control the spindle at 2800r The radial rotation accuracy is less than 0.05 μm and the axial rotation accuracy is less than 0.1 μm at the working speed per minute; 4. After the grinding disc is coated with diamond abrasive grains with a maximum diameter of 0.1 μm, the pre-grinding work is performed first, and then the diamond tool is sharpened. The specific operation steps are: install the diamond tool, adjust the level of the tool body fixture; turn on the air source, tu...

specific Embodiment approach 2

[0022] Specific implementation mode two: this implementation mode combines Figure 1-8 The processing method of diamond tools is introduced in detail:

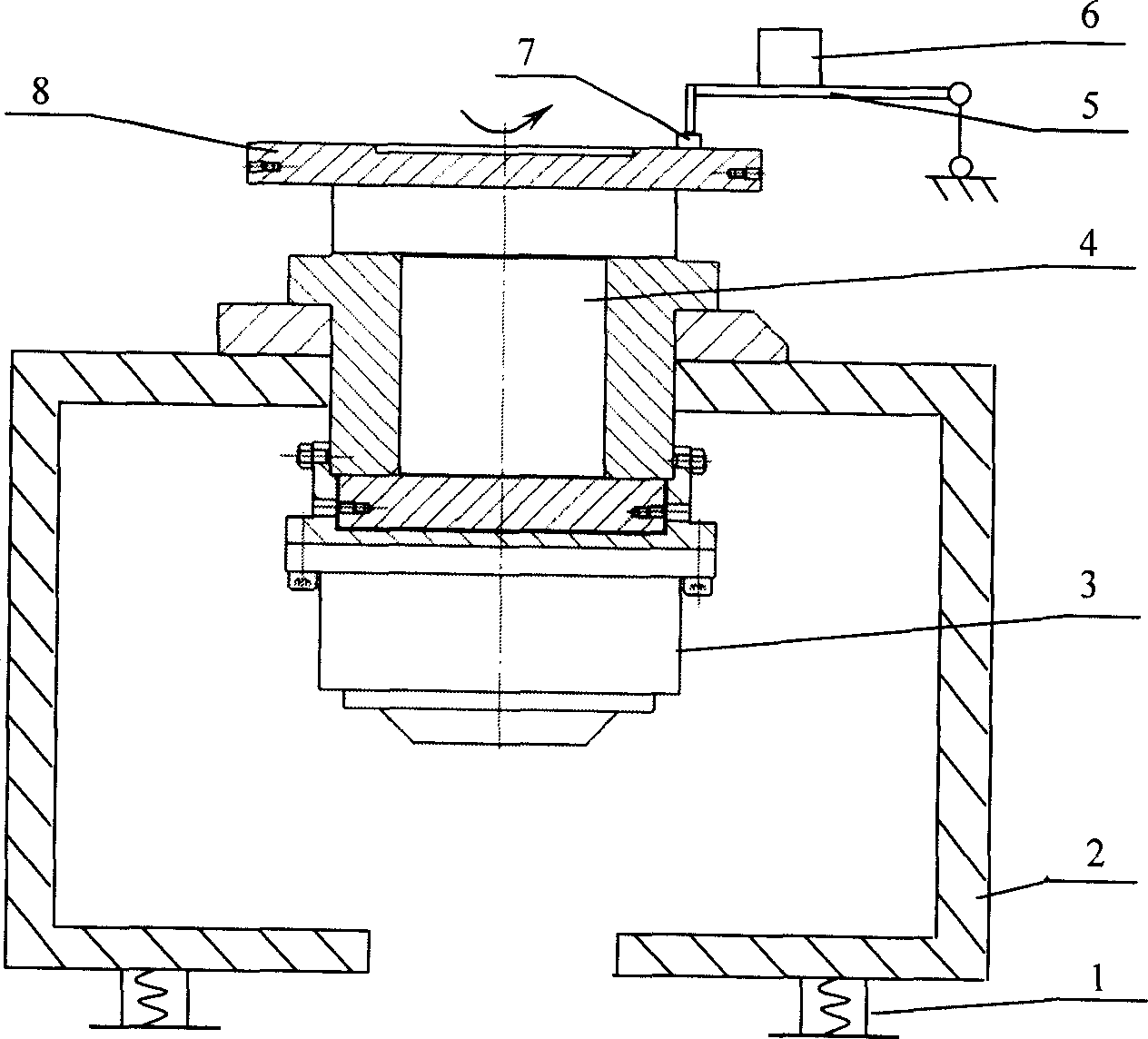

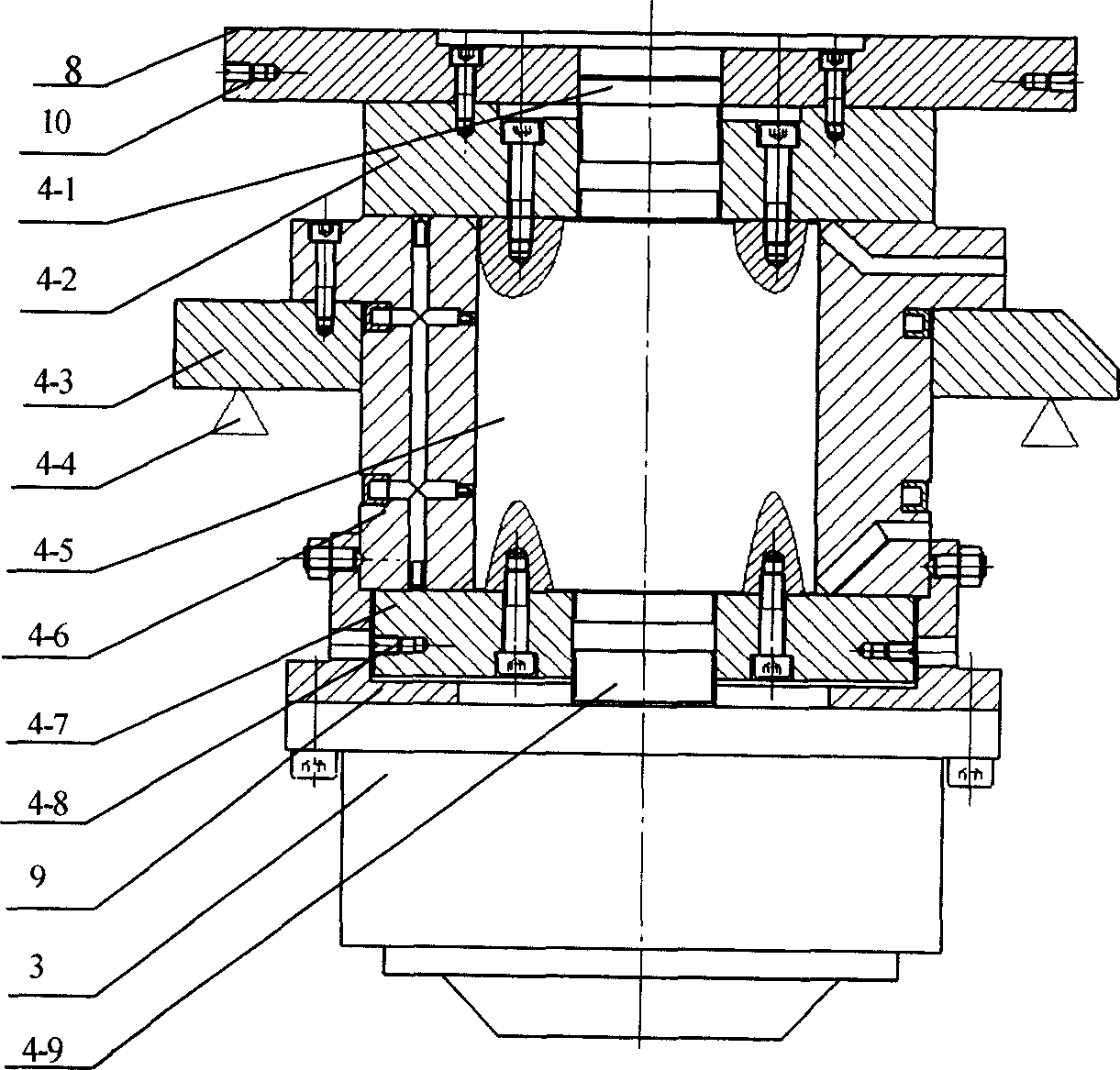

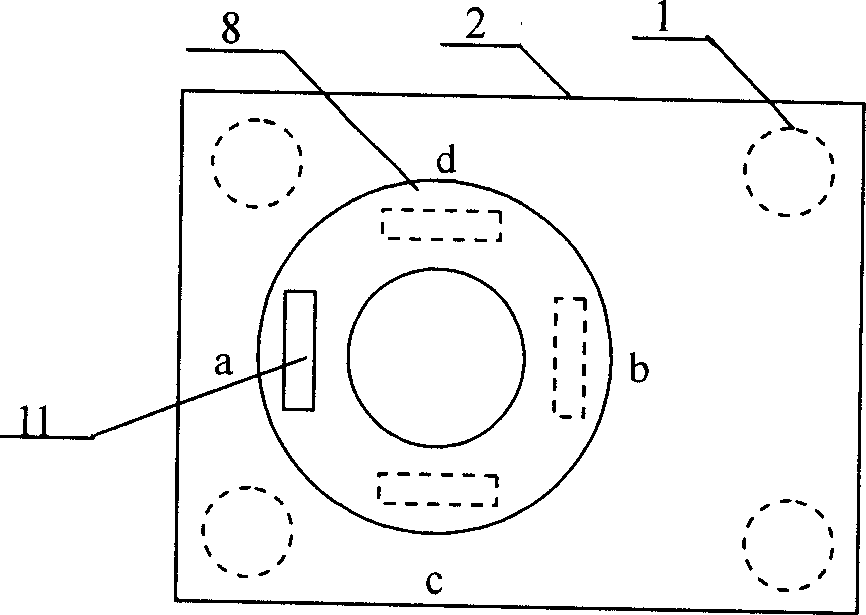

[0023] One, such as figure 1 As shown, the mechanical sharpening system for diamond tools in this embodiment consists of an air vibration isolation pad 1, a cast iron bed 2, a printing motor 3, an air static pressure spindle 4, a tool clamping system 5, a counterweight 6 and high phosphorus cast iron for grinding The air vibration isolation pad 1 is evenly distributed on the bottom of the cast iron bed 2, the lower part of the air static pressure spindle 4 is seated inside the cast iron bed 2, the upper end of the air static pressure spindle 4 is connected with a grinding disc 8, and the air static pressure spindle The end of 4 is connected with the output shaft of printing motor 3, and the top of grinding disc 8 is equipped with cutter clamping system 5, and counterweight 6 is placed on cutter clamping system 5. In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com