Process and apparatus for producing highly wear resistant diamond cutting wires

A high wear resistance, diamond technology, applied in the direction of metal sawing equipment, metal processing equipment, metal material coating technology, etc., can solve the problem of difficult production of diamond wire, inability to cut crystals, uniform thickness of diamond coating diameter and Uneven wire diameter and other problems, to achieve the effect of good wear resistance, low cutting cost and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

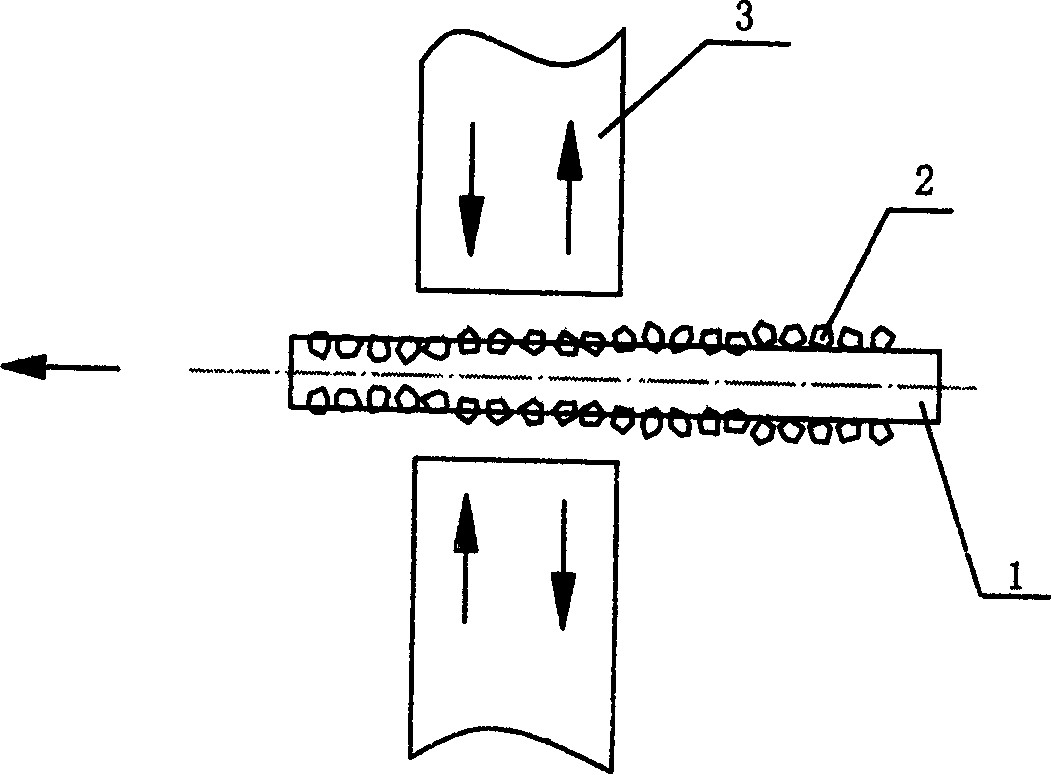

[0017] like figure 1 Shown is the working principle of the indenter die (3).

[0018] Firstly, a steel wire (1) with a diameter of 0.1-1 mm is selected according to cutting requirements, and the material of the steel wire (1) can be carbon steel or stainless steel. In order to improve the diamond setting strength, it is better to use steel wires with copper or nickel plating on the surface. Secondly, diamond particles (2) with an appropriate average diameter are selected according to the diameter of the steel wire (1). Generally, the diameter of the diamond particles (2) should not be greater than 1 / 2 of the wire diameter of the steel wire. If a steel wire of 0.1mm is selected, diamond particles with a particle size of 10 μm can be selected, and a metal coating of 1 μm is coated on the diamond particles at the same time. The metal coating can be nickel or copper. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com