Diamond fretsaw cutting method and device

A diamond wire saw and cutting equipment technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve the problem of low cutting speed, achieve fast cutting efficiency, fast cutting efficiency and accuracy, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

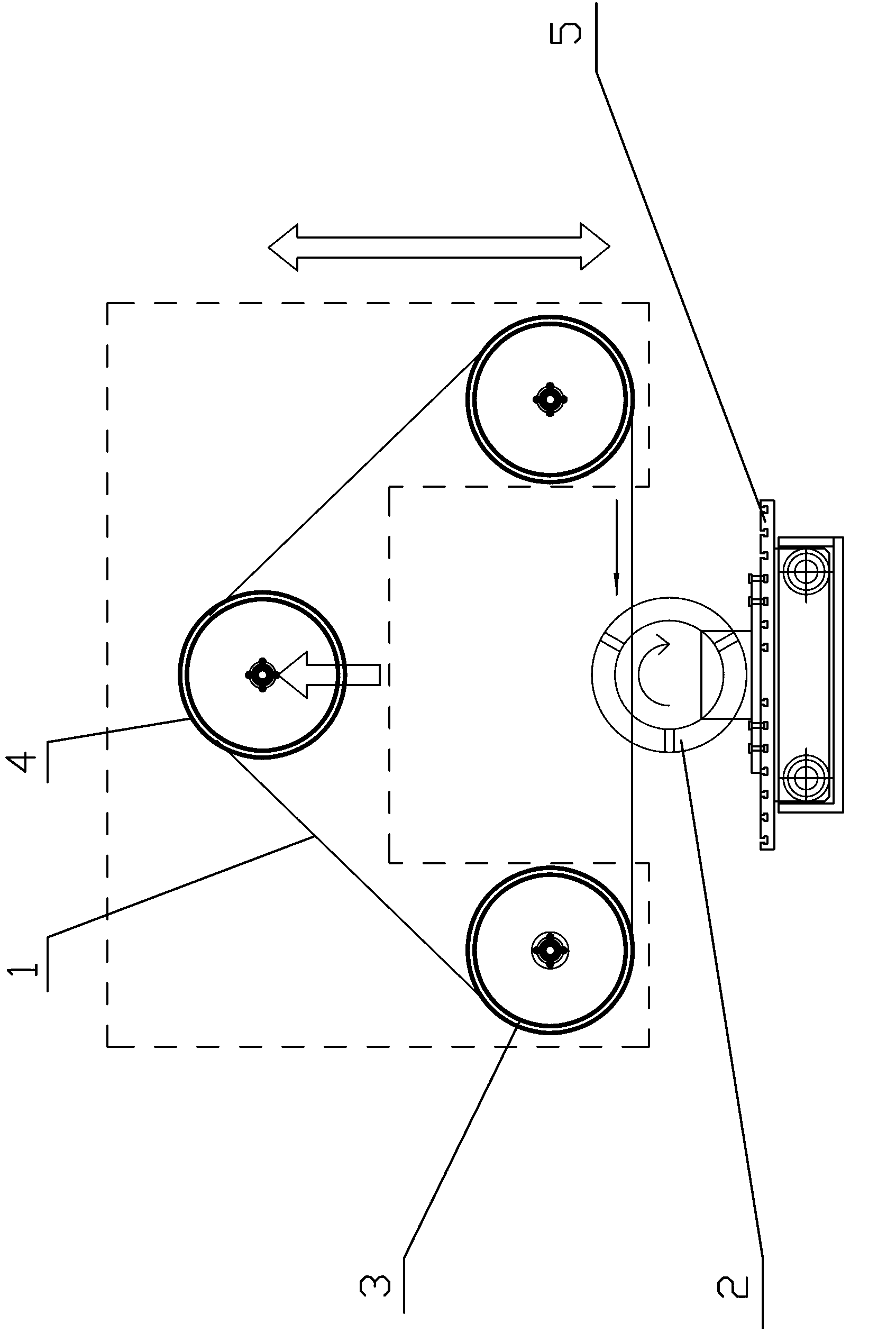

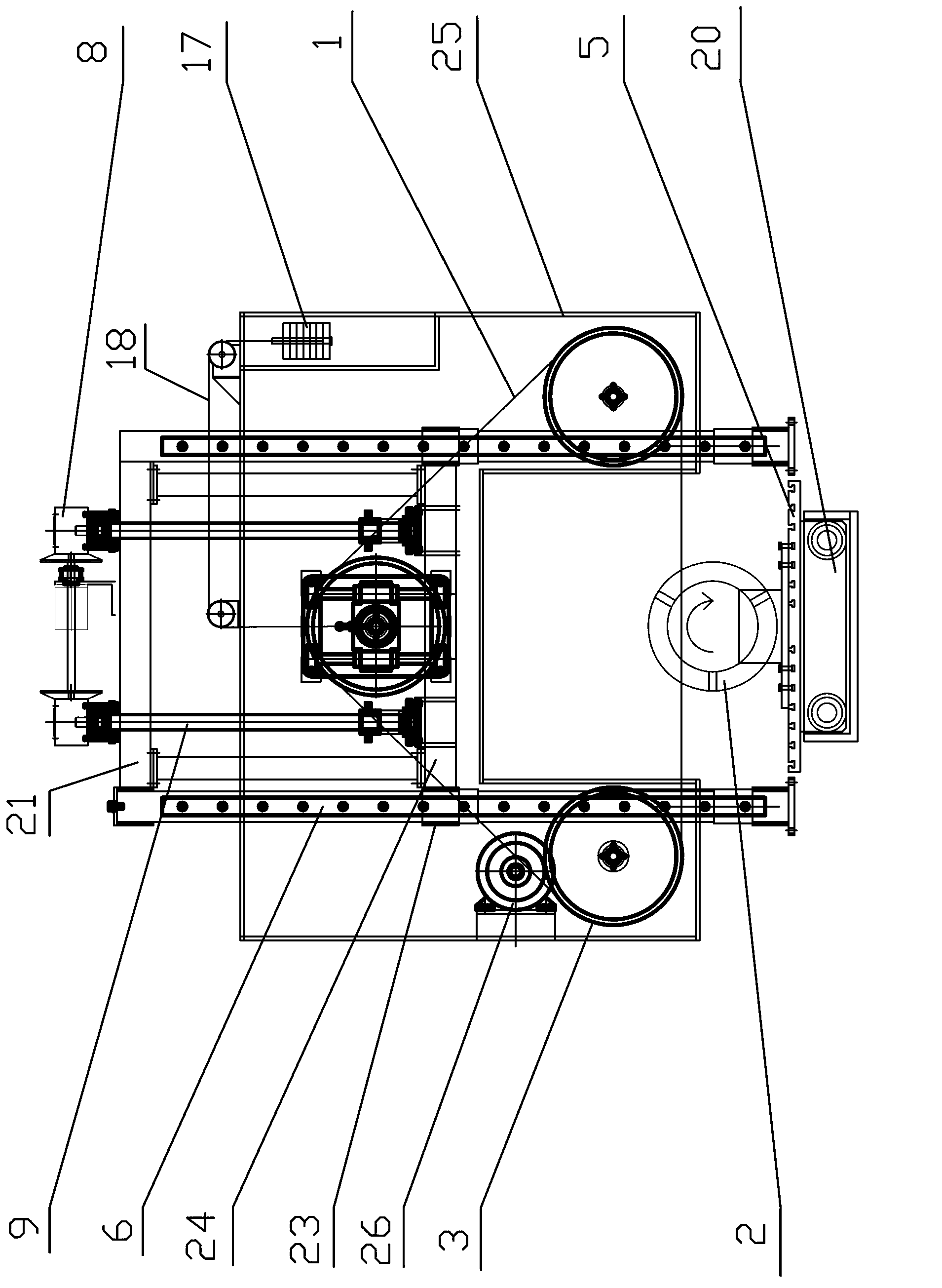

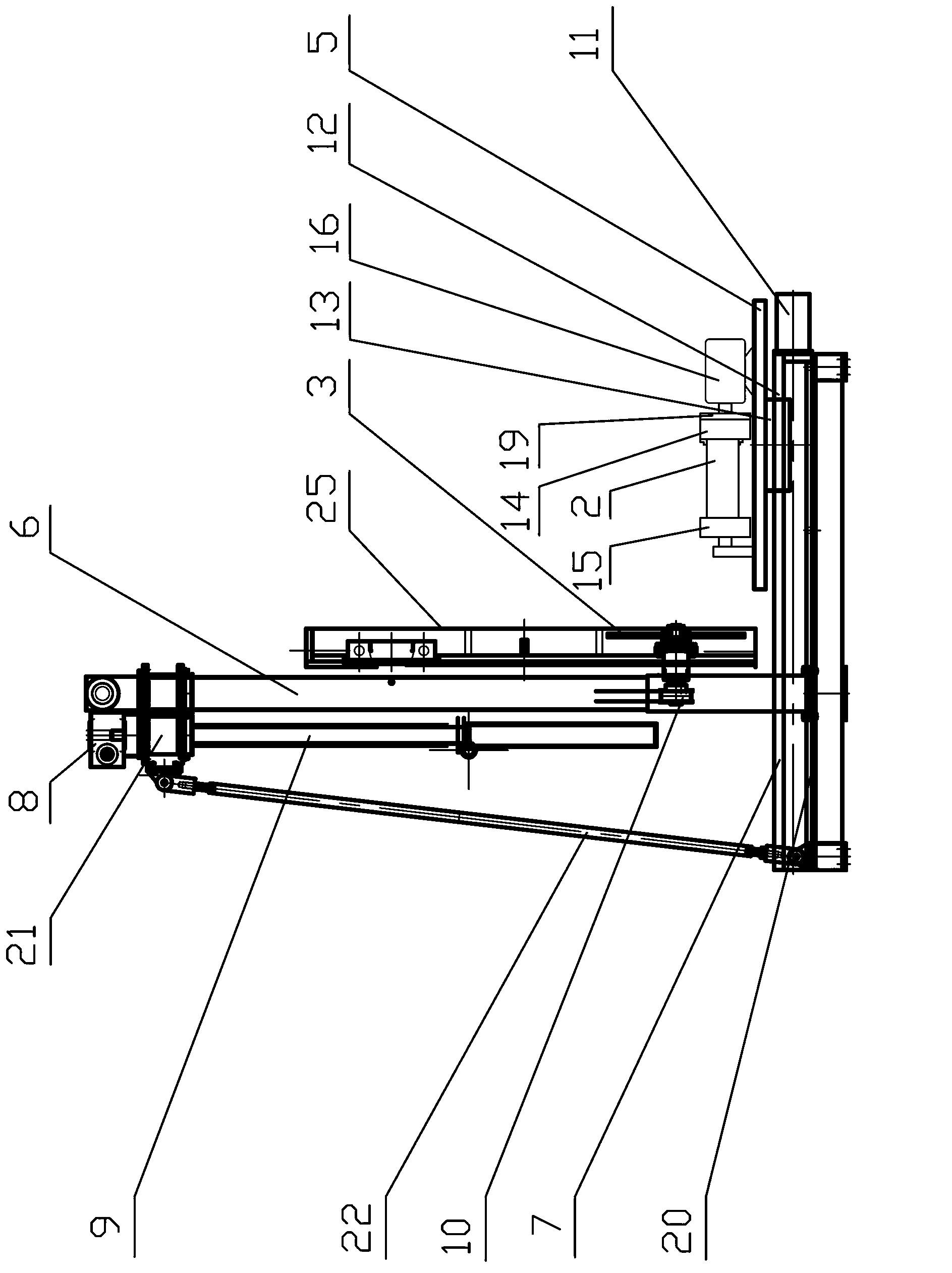

[0029] The diamond wire saw cutting equipment of the present invention includes an annular diamond wire saw 1 (a diamond wire formed by solidifying diamond on the surface of an annular steel wire by means of electroplating or resin coating), a wire saw operating mechanism and a wire saw feeding device, The workbench 5 carrying the crystal ingot workpiece 2, the workbench horizontal feed mechanism, the base 20 and the frame.

[0030] Described frame is made of two vertical guide rails 6 and crossbeam 21, and described vertical guiderail 6 is fixed and upright on the base 20, and described crossbeam 21 is straddled on two vertical guide rails 6 and is fixed, and uses the auxiliary positioning of diagonal tie rod 22; The vertical guide rail 6 is equipped with a slide block 23, and a truss 24 is connected between the two slide blocks 23, and a lif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com