Cutting device and method of glass substrate

A cutting device, glass substrate technology, applied in glass cutting devices, glass manufacturing equipment, fine work devices, etc., can solve the problems of scratches or pollution of glass surfaces and lines, environmental pollution of dust-free workshops, and impact on product quality, etc. , to avoid scratching the glass substrate circuit, reduce glass debris, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

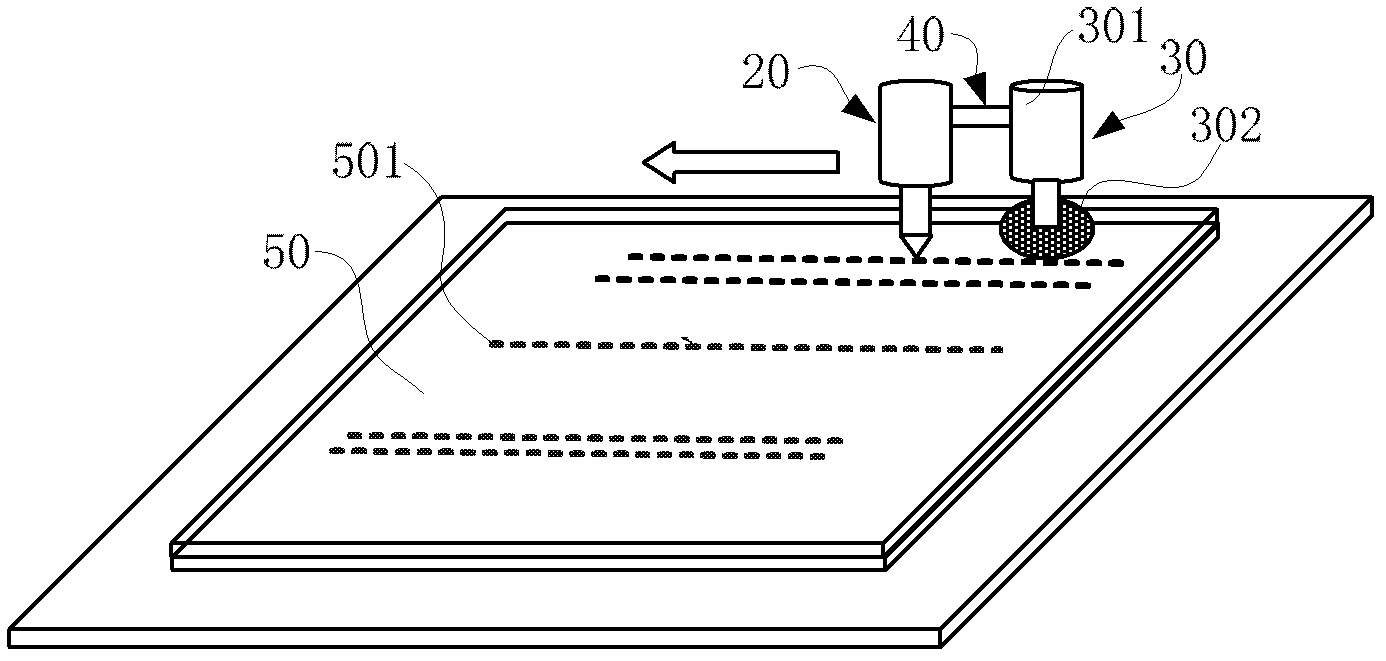

[0026] Please also refer to Figure 3 to Figure 5 , the glass substrate cutting device of the first embodiment of the present invention comprises a first laser emitting device 20, a first cutting device 30 and a connecting device 40, the first laser emitting device 20 and the first cutting device 30 are arranged oppositely along the cutting movement direction, connected The device 40 connects and holds the first laser emitting device 20 and the first cutting device 30, and the connecting device 40 can be fixed between the first laser emitting device 20 and the first cutting device 30, and can also be movably connected to hold the first laser emitting device 20 and the first cutting device 30. The laser emitting device 20 and the first cutting device 30, so that the relative positions of the first laser device 20 and the first cutting device 30 can be adjusted and corrected.

[0027] The first laser emitting device 20 may include a cooling device (not shown in the figure), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com