Ratcheted pivot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

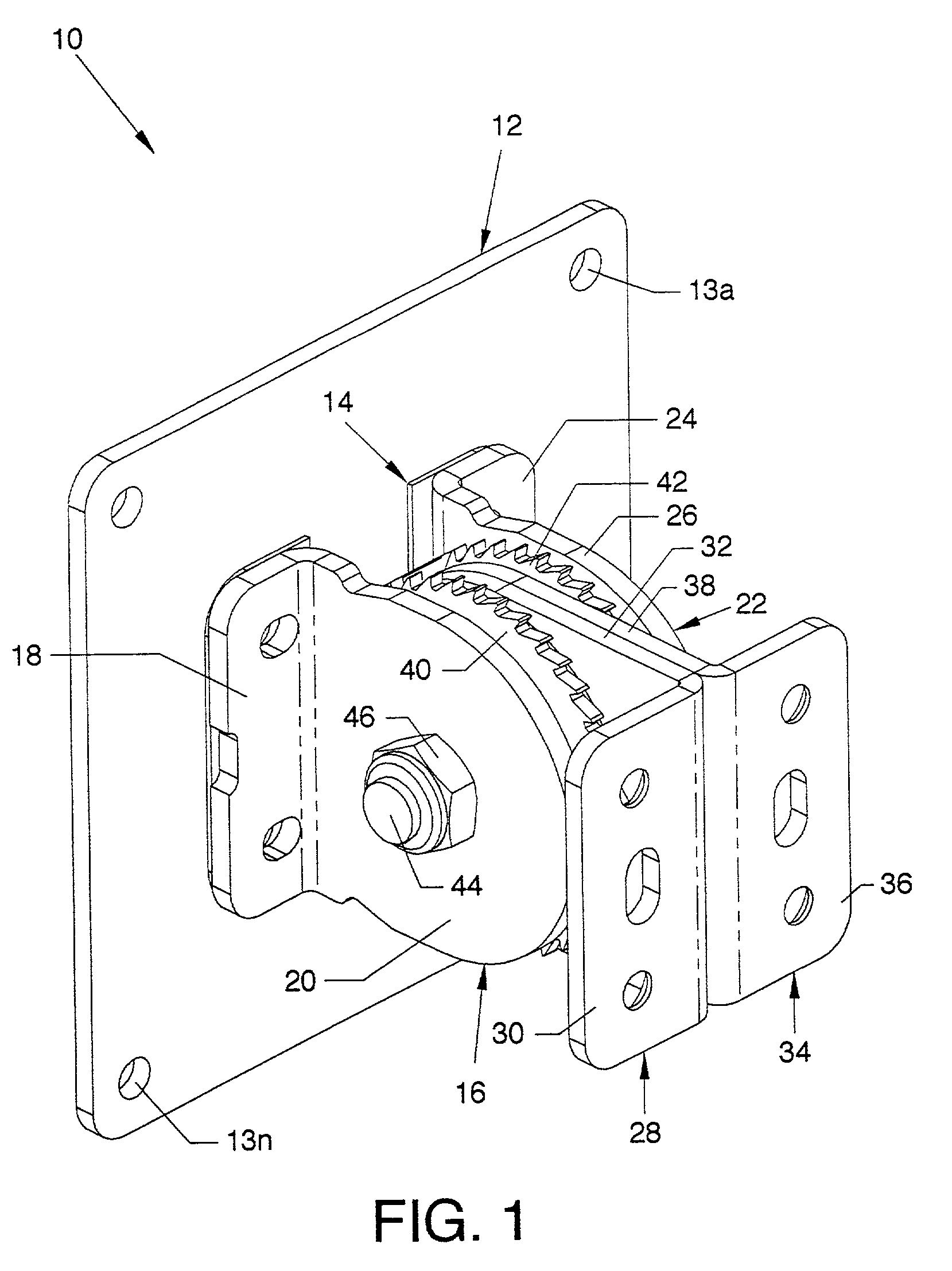

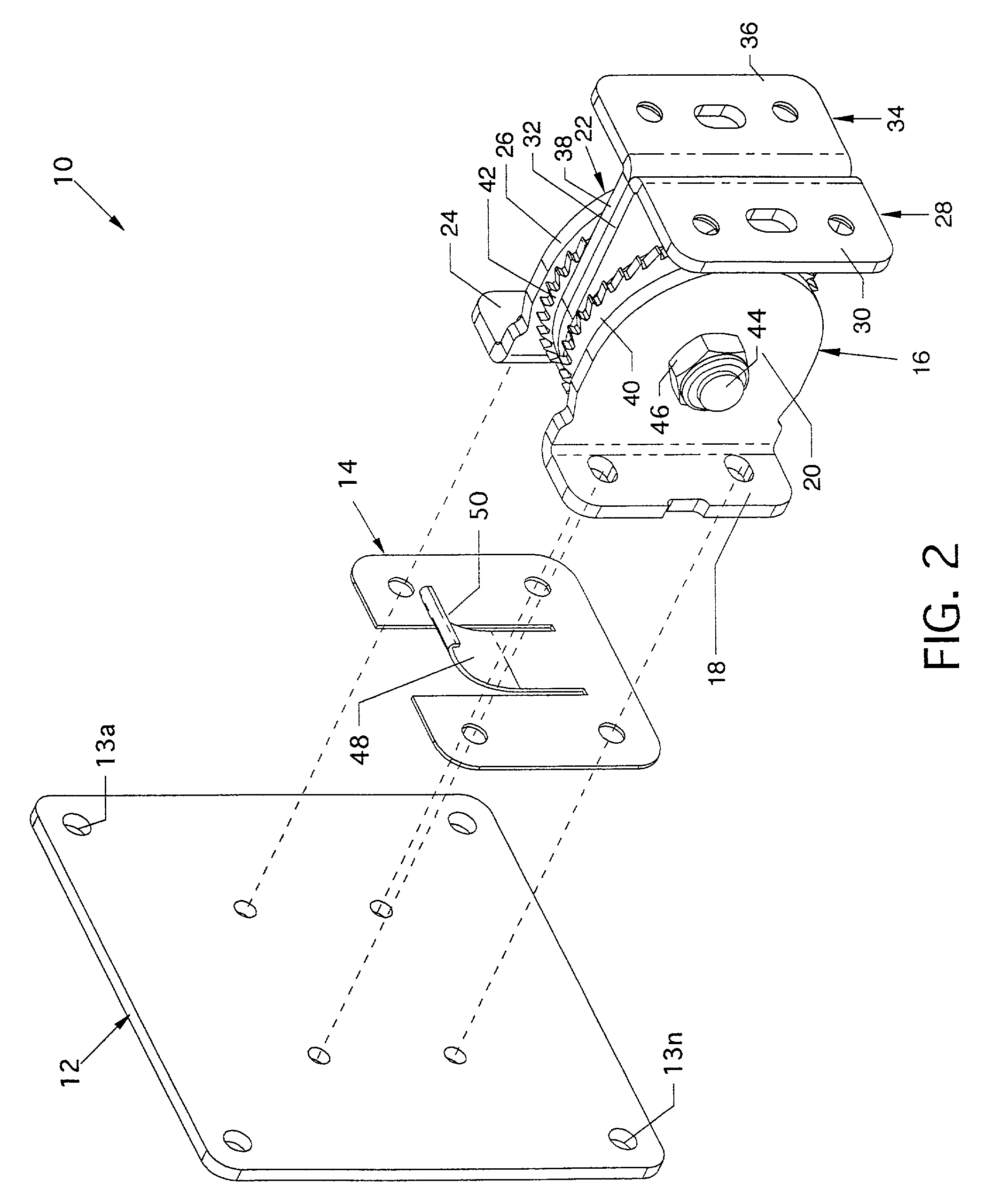

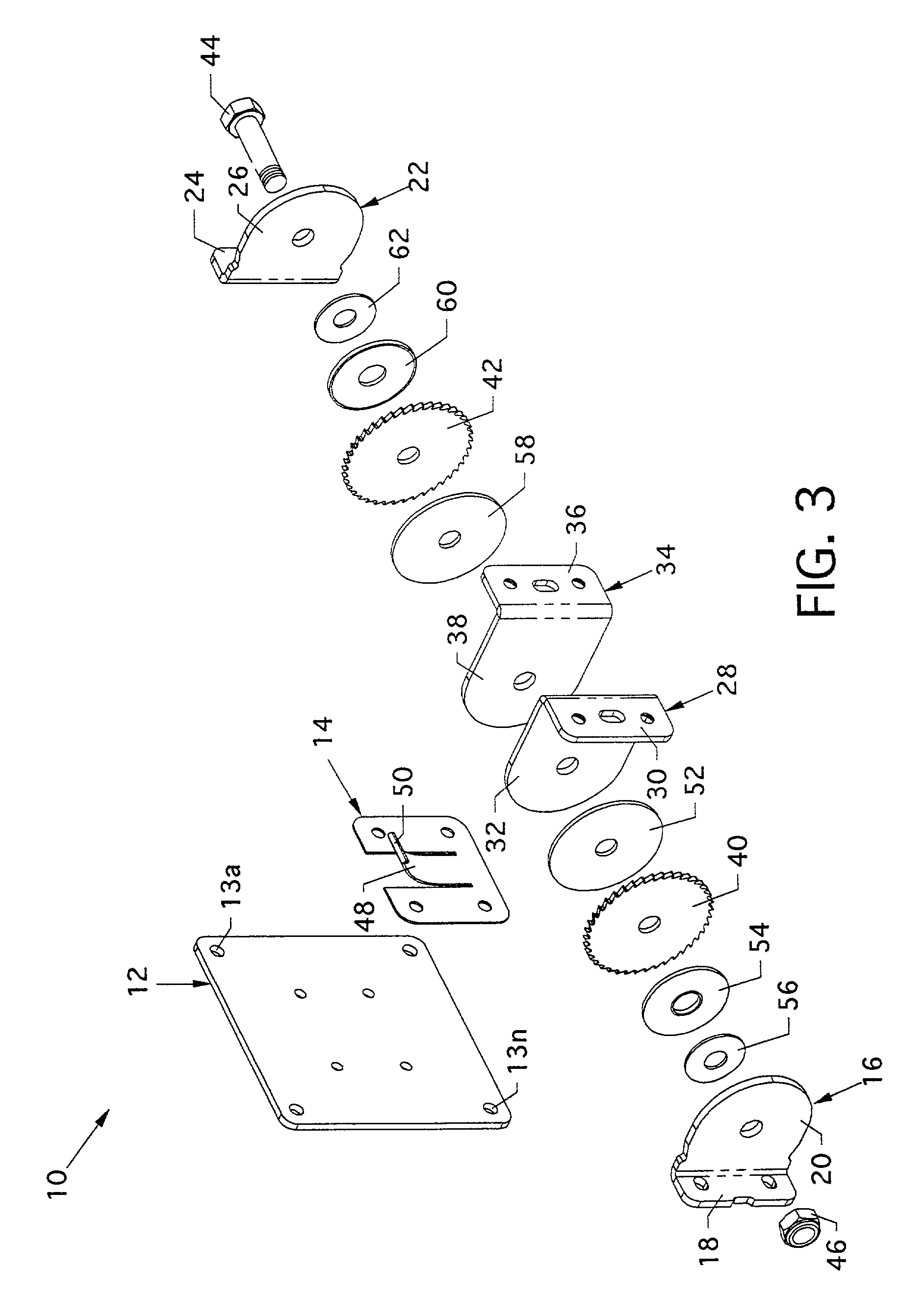

[0025] The operation of the ratcheted pivot 10 provides for rotation of a monitor of other device which secures to the mounting plate 12 about the horizontal axis described by the pivot bolt 44. Rotation is made about the horizontal axis to rotatingly position the mounting plate 12 to gain a desired angle of adjustment suitable for use with the load provided by the monitor or other device supported by the ratcheted pivot 10. Movement and rotation in two directions are provided for. Pivot bolt 44 and nut 46 are tightened across the assembled components of the ratcheted pivot 10 to provide suitable friction to stabilize the ratcheted pivot 10 and the load attached to the mounting plate 12 to prevent the ratcheted pivot 10 and attached load from weight induced rotation about the pivot bolt 44. Friction is applied across the ratcheted pivot 10 in general to bring together components in repositional frictional engagement having relatively small or relatively large areas of contact. An ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com