Small-sized beacon ship

A navigation aid ship, small technology, applied in the direction of hull, hull deck, ship construction, etc., can solve the problems of channel restrictions, hydrological conditions and high requirements for berthing facilities, reducing the equipment utilization rate of engineering application units, and low operating capacity of small navigation aid ships. , to achieve good market promotion prospects, low operation and maintenance costs, and reasonable deck main equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

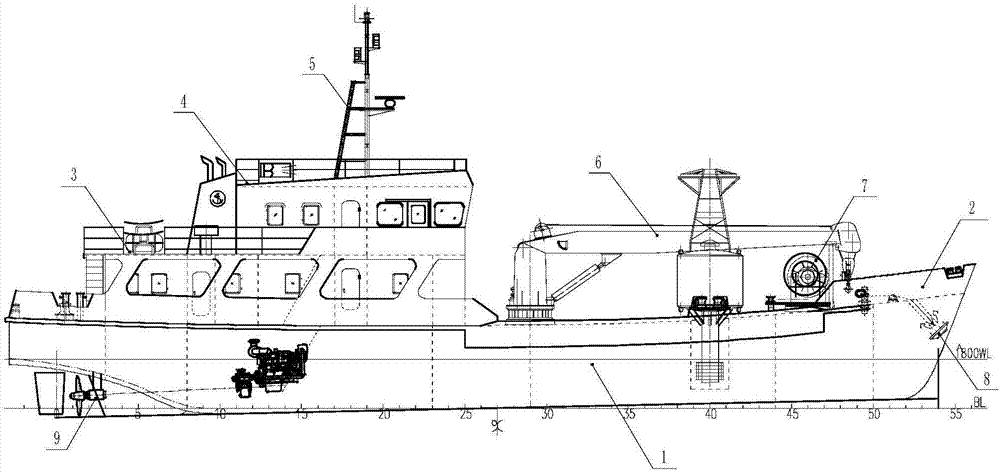

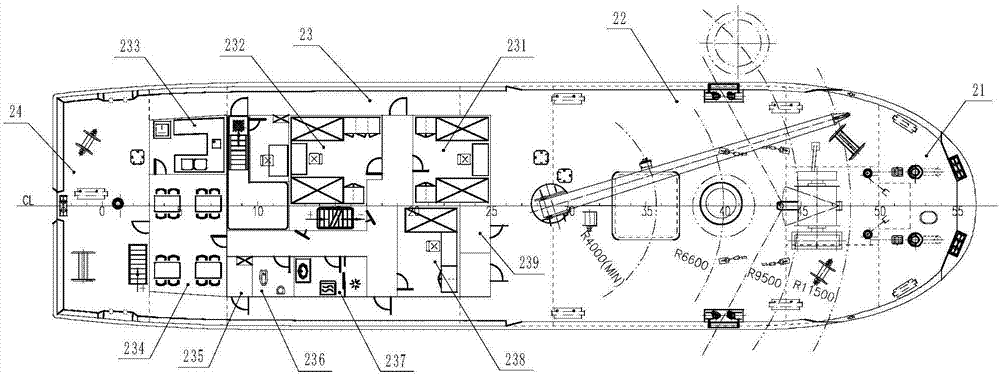

[0048] A small navigation mark ship, which: includes a bilge 1, a main deck 2, a driving deck 3, a compass splint 4, a communication antenna 5, a hydraulic slewing crane 6, a horizontal hydraulic winch 7, navigation and mooring equipment 8 and a propeller 9. The main deck 2 is fixedly installed on the top of the hold 1, the driving deck 3 is installed above the main deck 2, the compass splint 4 is installed above the driving deck 3, and the communication antenna 5 is fixedly installed On the compass splint 4, the hydraulic slewing crane 6, the horizontal hydraulic winch 7 and the navigation anchoring equipment 8 are all installed on the main deck 2 and are all located on the right side of the driving deck 3, and the described propeller 9 is installed on the bottom. Aft of cabin 1.

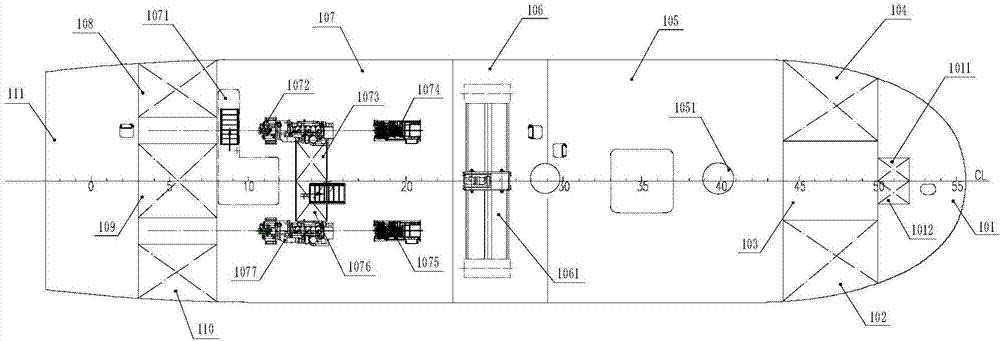

[0049] In the embodiment, the bottom tank 1 is composed of a fore pea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com