Diesel engine integrated power supply system

A technology of power supply system and diesel engine, which is applied in the direction of mechanical equipment, engine components, combustion engines, etc., can solve the problem of low utilization rate of exhaust energy, achieve the effect of enhancing energy saving and emission reduction, increasing the proportion, and increasing the self-generated energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

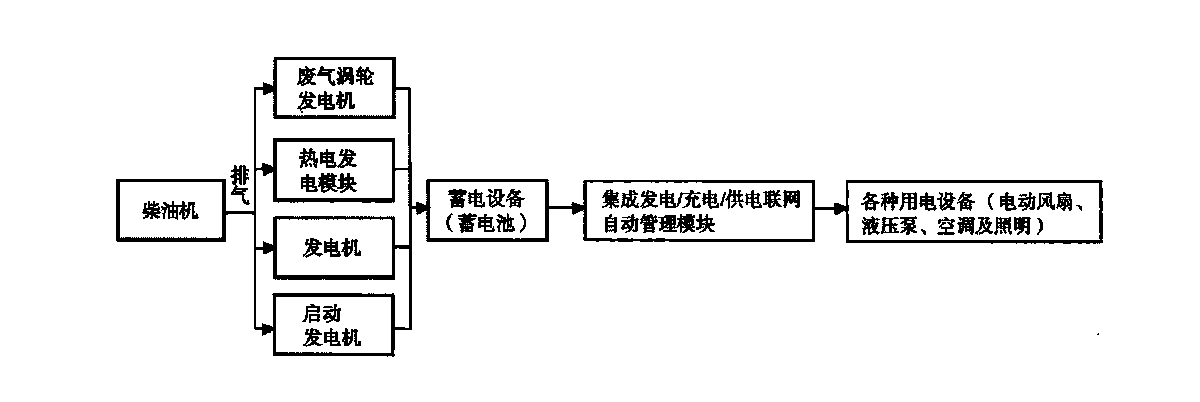

[0012] In the diesel engine integrated power supply system described in the present invention, the exhaust device of the diesel engine is respectively connected with the exhaust gas turbine generator, the thermoelectric power generation module, the generator and the starter generator; then the exhaust gas turbine generator, the thermoelectric power generation module, the generator and the starter generator Then they are respectively connected with the electric storage equipment; the electric storage equipment is connected with the automatic management module and various electric equipments. Wherein said starter generator is a dual-mode reversible motor. When the vehicle brakes and goes downhill, it is used as a generator to recover braking energy and convert downhill energy into electrical energy. If the power generation can meet the power demand of the model, some integrated modules can be canceled to reduce the number of components and reduce the energy consumption of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com