Copper covered aluminum wire forming technique

A copper-clad aluminum wire and forming process technology, applied in metal extrusion dies and other directions, can solve the problems of low production efficiency, affecting the conductivity of copper-clad aluminum wire, poor bonding quality of copper-aluminum interface, etc. The effect of good bonding of aluminum interface and reduction of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

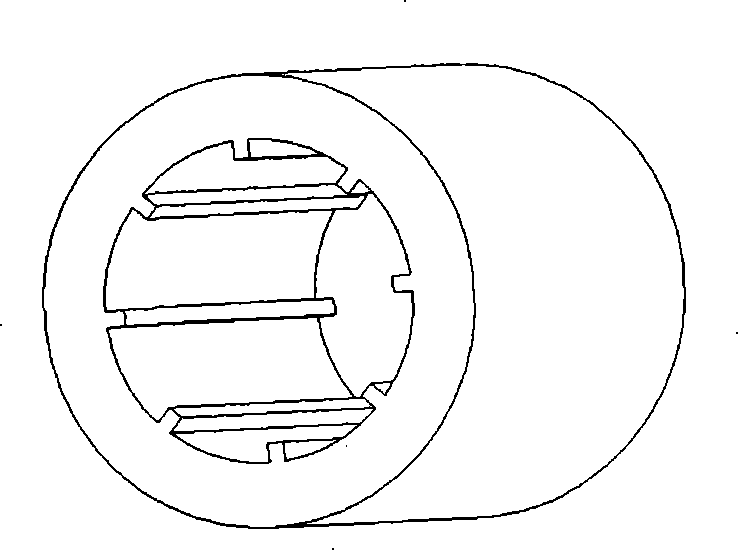

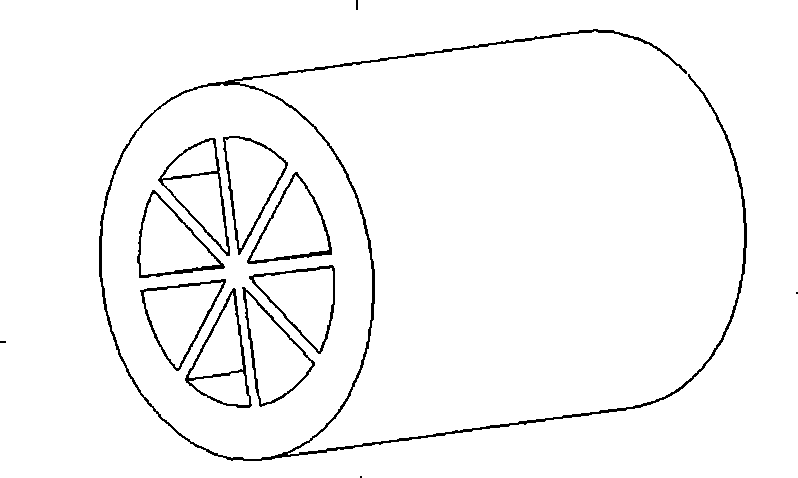

[0020] a. Process the copper tube into a copper tube with an outer diameter of Φ100, an inner diameter of Φ90, and a rectangular rib on the inner wall (see figure 2 ), the rib height is 5mm, and the width is 10mm.

[0021] b. Heat the copper tube to 250°C, and use a low-pressure casting process to die-cast aluminum liquid into the copper tube, and the die-casting temperature is 700°C.

[0022] c. After the copper pipe is cooled to 200°C, put it into the mold of the extrusion machine and extrude it. The extrusion ratio is 10:1, and extrude the copper-clad aluminum wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com