Copper cladding aluminium wire, copper cladding aluminium pipe production process and its equipment

A production process, copper-clad aluminum wire technology, applied in the direction of conductive materials, conductors, conductive materials, etc., can solve the problems that affect the quality stability of copper-clad aluminum wire, increase the difficulty of stretching process, and difficult to control the stretching quality, etc., to achieve The effect of improving material utilization, saving copper, and reducing the number of drawing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

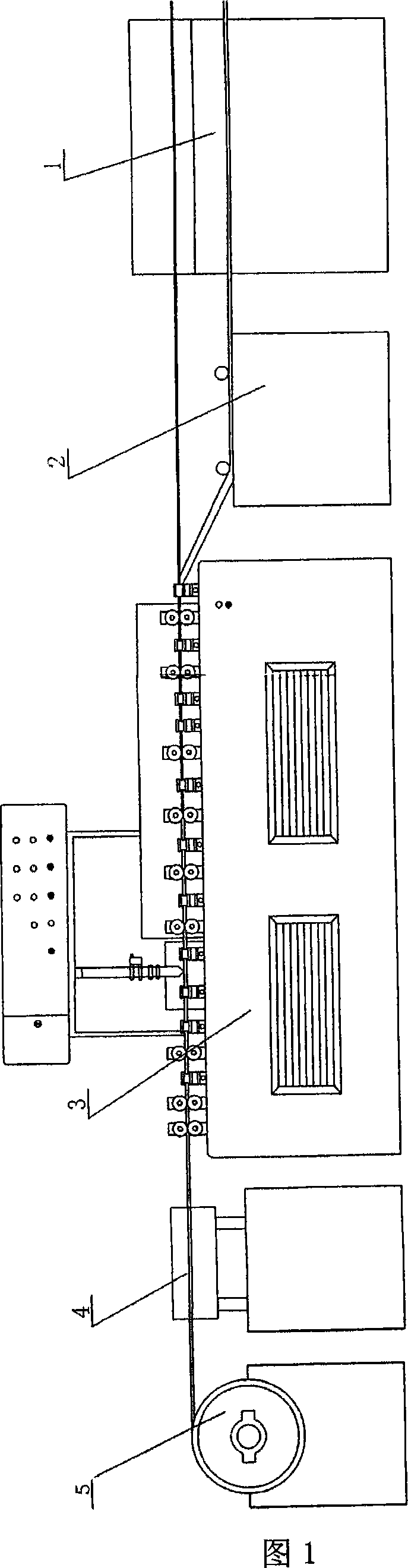

[0017] Embodiments of the present invention are described with reference to the accompanying drawings. The figure shows a schematic diagram of the front view of the equipment for producing copper-clad aluminum wires (tubes). Among them, 1 is the surface cleaning machine for aluminum billet core, 2 is the surface cleaning machine for copper strip, 3 is the cladding welding mechanism, and placed in an inert gas protection environment, 4 is the online intermediate frequency heating device, 5 is the wire take-up machine and its Stretching machine. The cladding welding mechanism 3 is composed of multi-stage vertical forming rollers whose numbers are gradually reduced to the cavity and multi-stage horizontal forming rollers whose numbers are gradually reduced to the cavity. The welding machine is an automatic welding pipe argon arc welder.

[0018] The process of preparing copper-clad aluminum wire (pipe) with the above-mentioned equipment is as follows:

[0019] a. According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com