Patents

Literature

37results about How to "Reasonable process arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

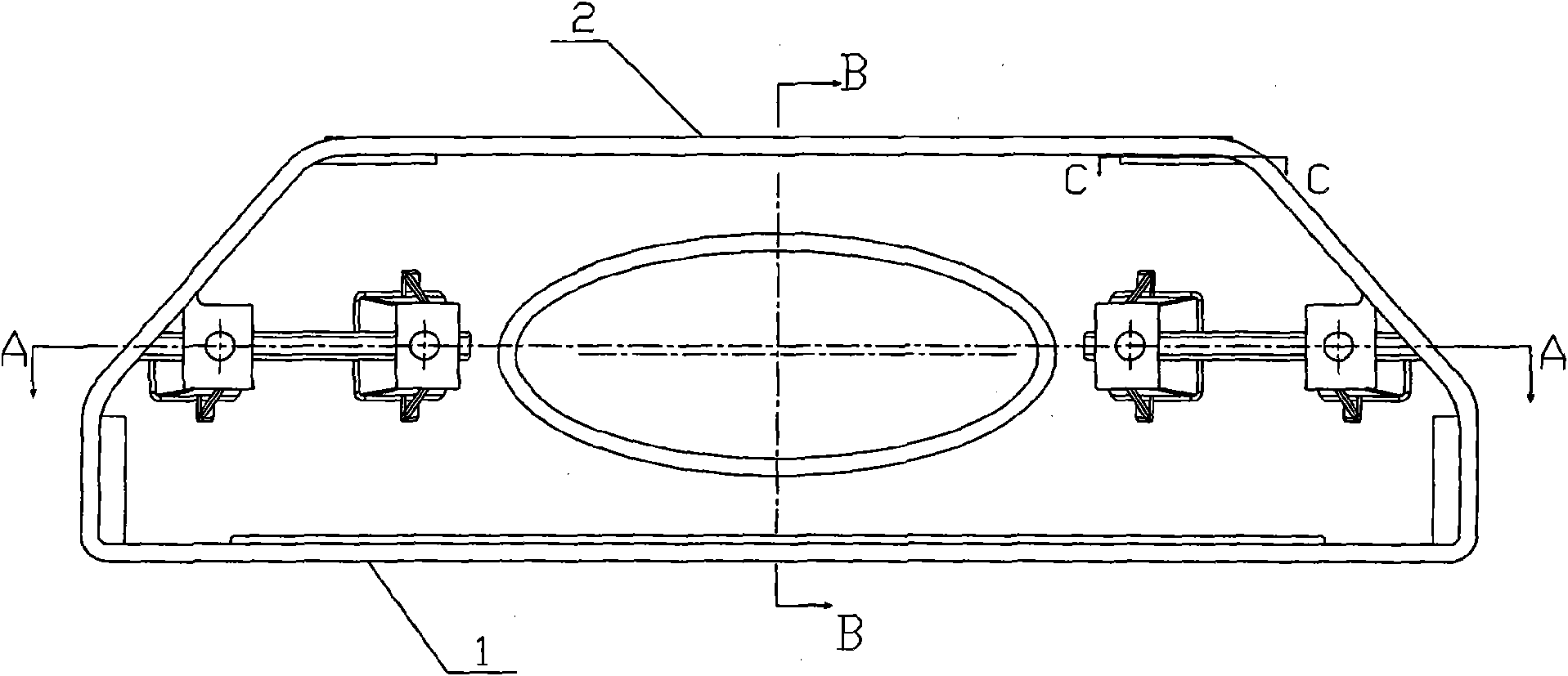

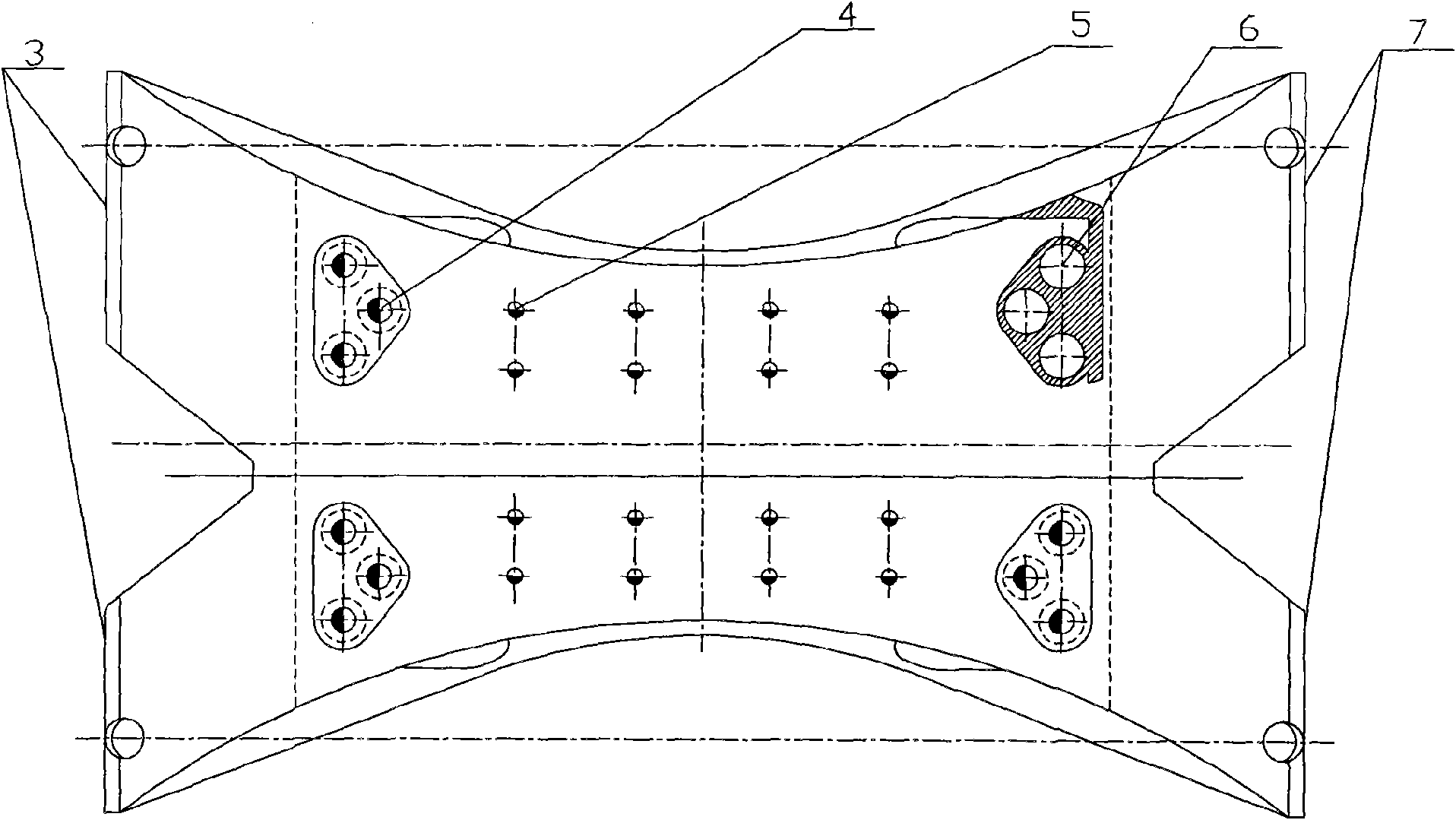

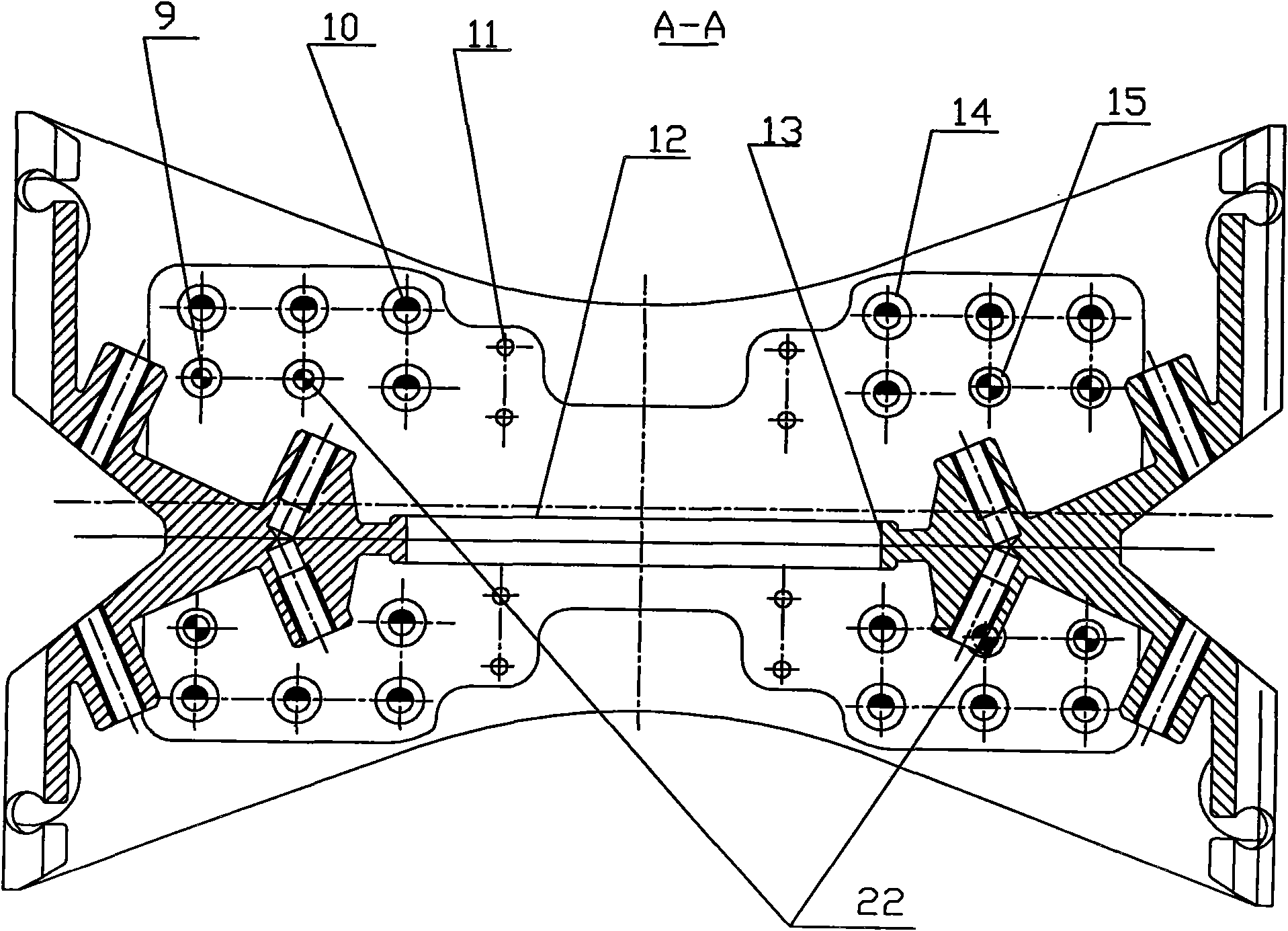

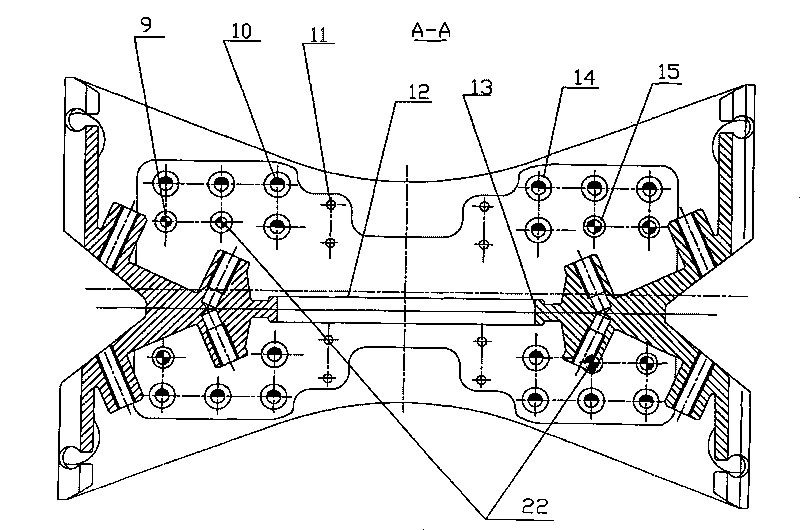

Thin-wall elliptical part numerical control machining method

A thin-wall elliptical part numerical control machining method includes the steps of firstly, feeding; secondly, roughly turning; thirdly, milling process reference; fourthly, drilling; fifthly, roughly milling an elliptical inner cavity; sixthly, precisely milling the elliptical inner cavity; seventhly, roughly milling an outer annular groove; eighthly, precisely milling the outer annular groove; ninthly, precisely turning outer allowance. By the method reasonable in process arrangement, deformation of thin-wall elliptical parts is avoided effectively, machining quality of elliptical thin-wall parts is guaranteed, and the machining bottleneck of special-shaped elliptical thin-wall parts is solved.

Owner:NORTH CHINA INST OF AEROSPACE ENG

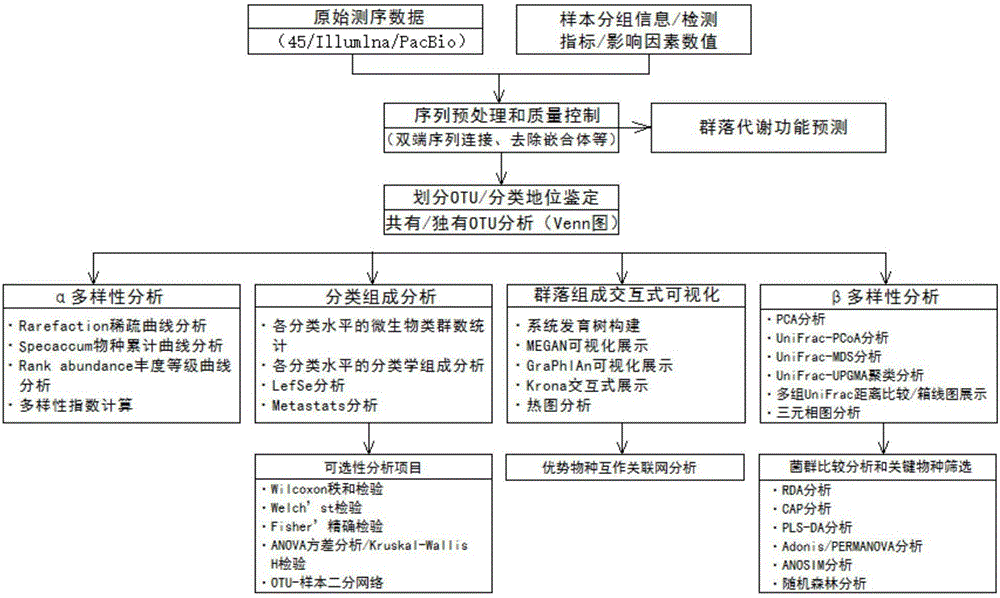

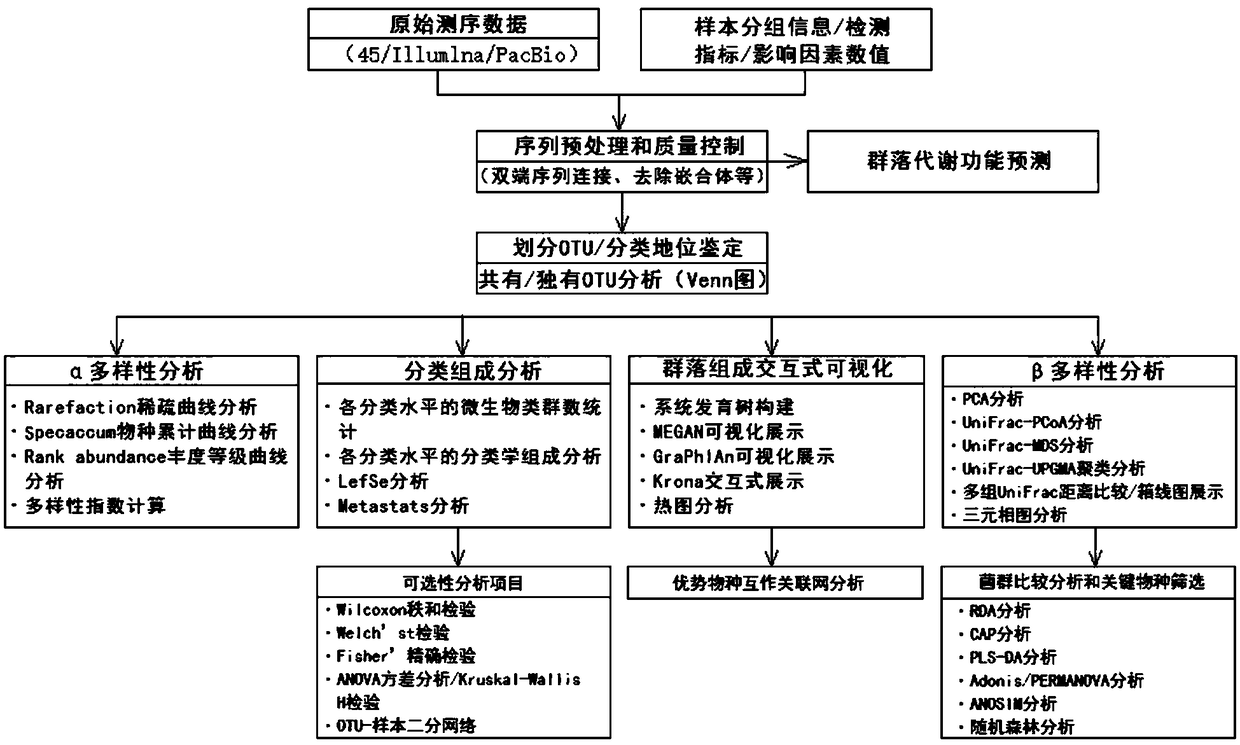

Automatic method for analyzing constitution and diversity of bacterial community of 16SrRNA gene

ActiveCN106815492AVarious methods of data mining analysisIn-depth analysis of data mining methodsSequence analysisSpecial data processing applicationsTechnical standardModularity

The invention discloses an automatic method for analyzing constitution and diversity of a bacterial community of a 16SrRNA gene. The automatic method comprises the following steps: in 16SrRNA sequencing data analysis process, by taking original sequencing sequence data as input, calling a standard analysis tool (such as Mothur and QIIME) of the industry, and performing visualization on data finally, thereby obtaining analysis results which are easy to analyze. The automatic method includes popular main analysis items at present, meanwhile analysis contents can be modularized, relatively rich and deep data mining analysis methods can be available, different analysis module contents can be combined according to different demands, and process procedures can be relatively reasonably arranged; and in addition, analysis errors caused by different sequencing depths can be eliminated, and the analysis results can be relatively comprehensive, accurate and reliable.

Owner:SHANGHAI PASSION BIOTECHNOLOGY CO LTD

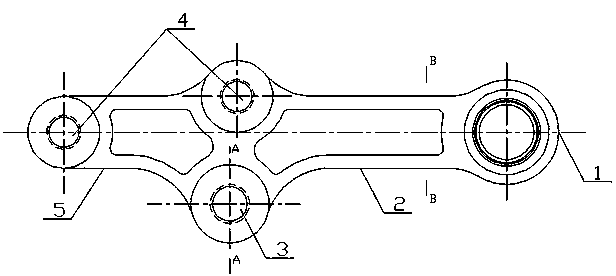

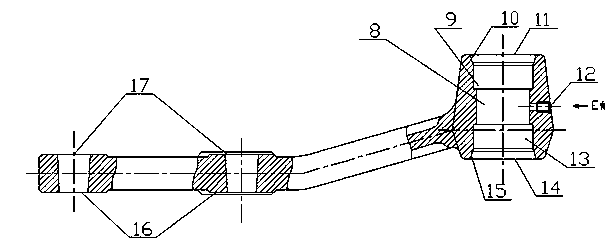

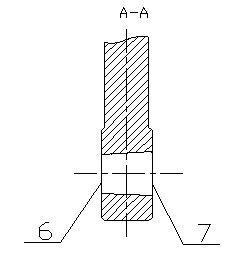

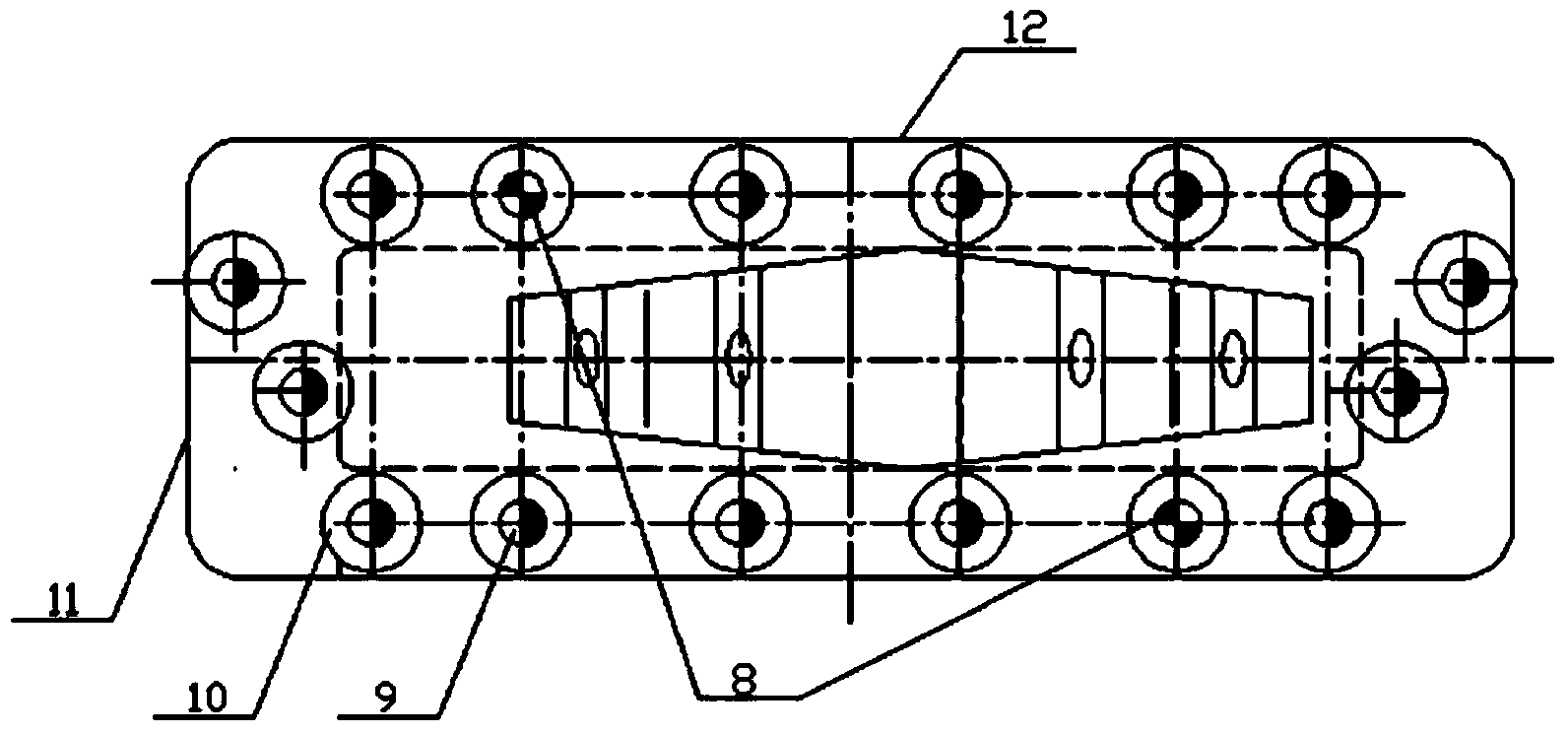

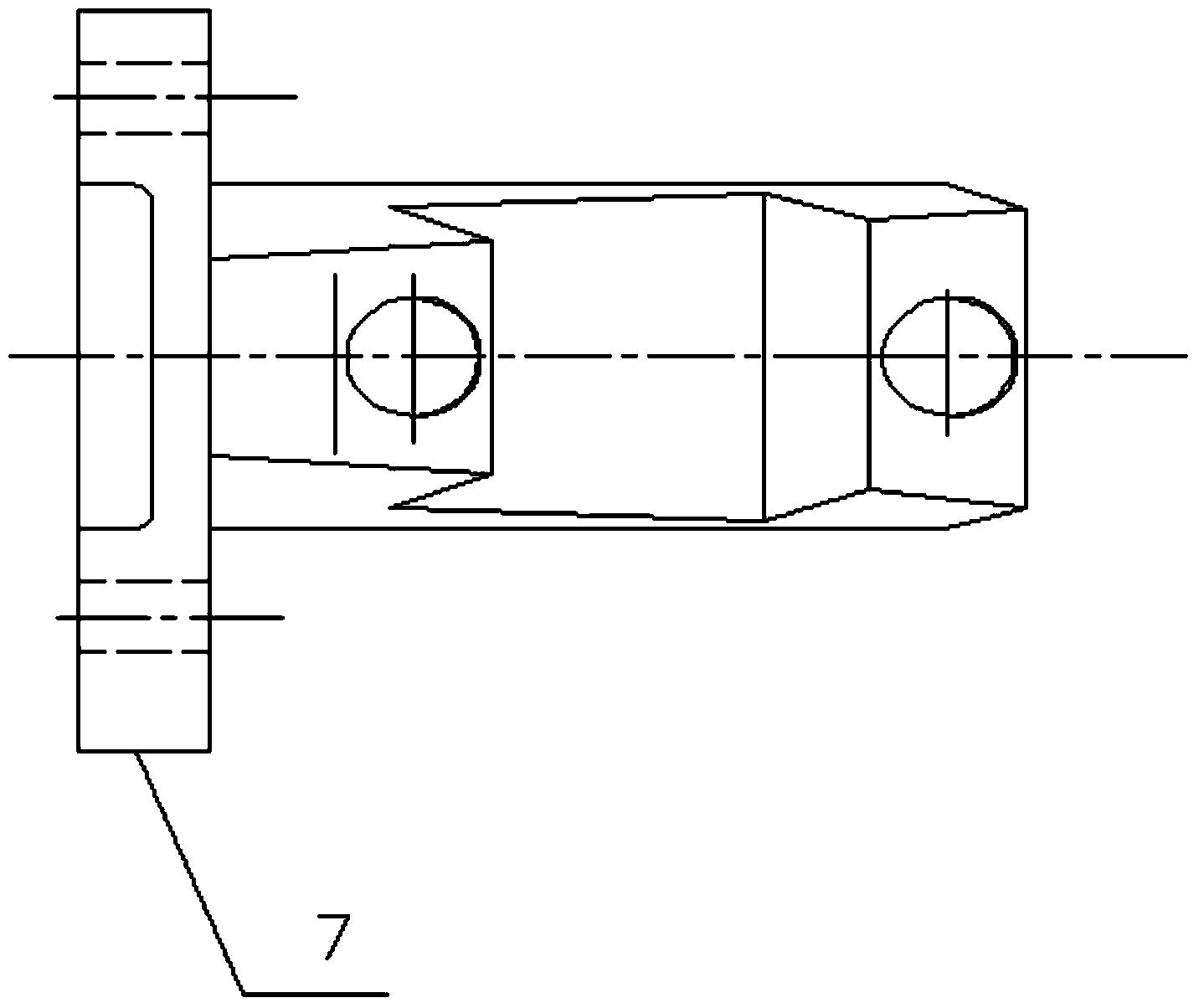

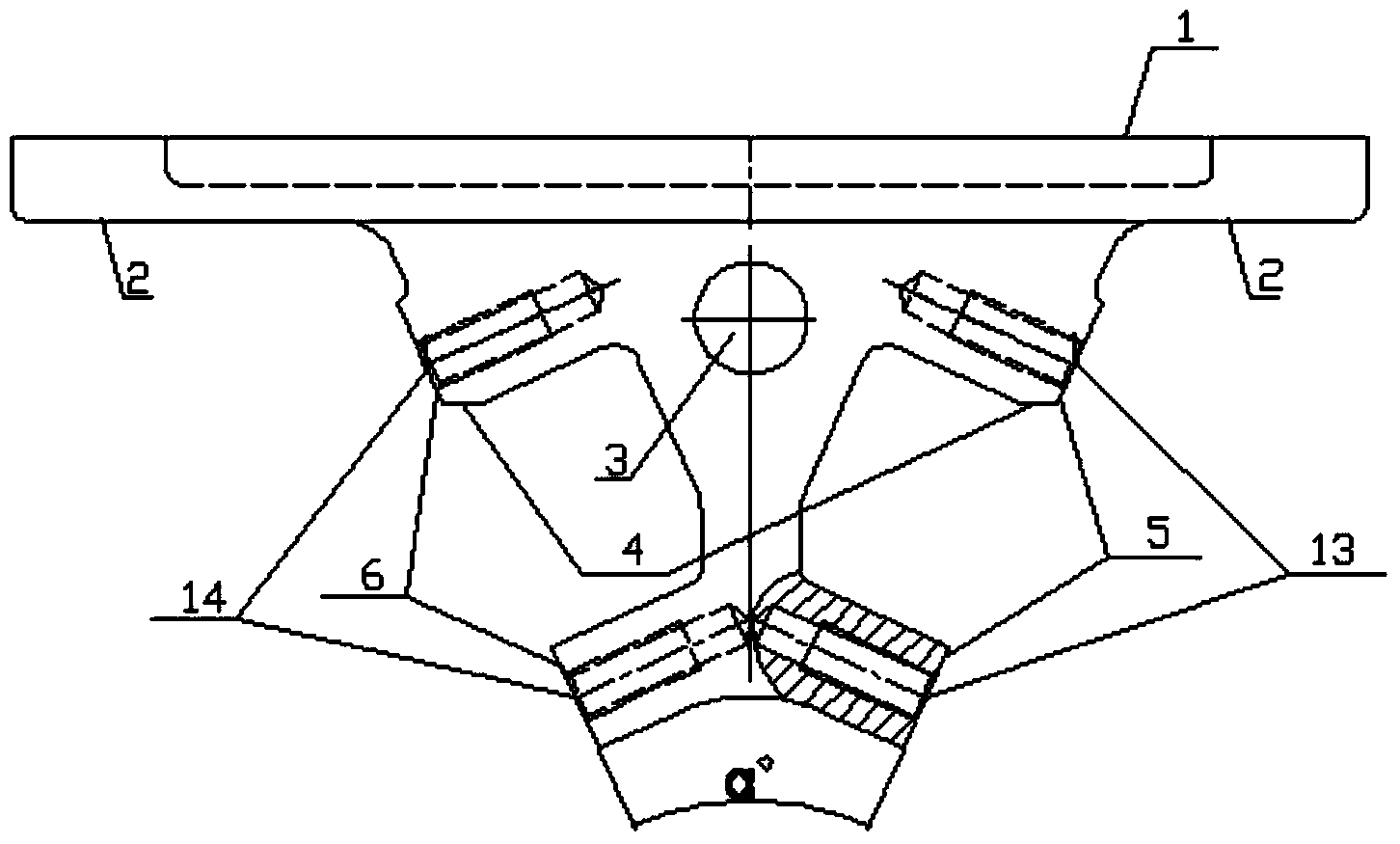

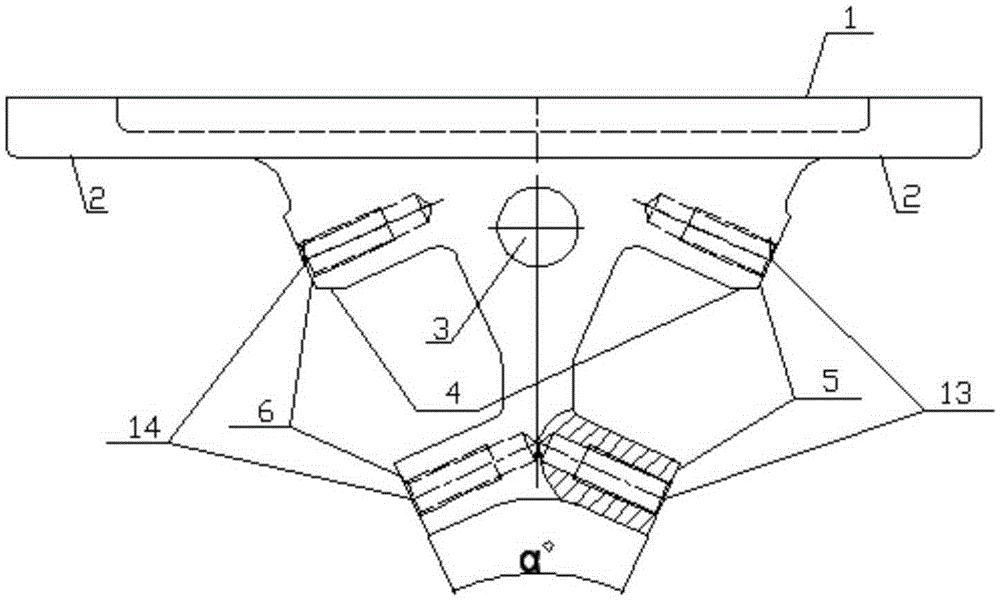

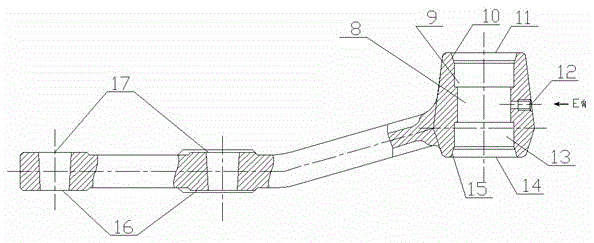

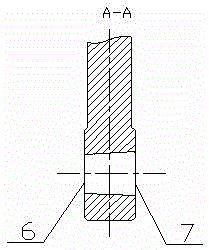

Process for machining transition swing arms of steering devices of heavy-duty automobiles

The invention relates to the technical field of accessories of automobiles, in particular to a process for machining transition swing arms of steering device systems of heavy-duty automobiles. The process includes milling upper end surfaces of large balls; milling lower end surfaces of the large balls; drilling auxiliary positioning holes; boring the auxiliary positioning holes; milling small end surfaces of large and small taper holes; milling large end surfaces of the large and small taper holes; lathing upper-end inner holes and taper holes of the large balls; lathing lower-end inner holes and taper holes of the large balls; drilling and reaming the large and small taper holes; milling planes of threaded holes; drilling and tapping the threaded holes. The process has the advantages that the transition swing arms are machined on various common machine tools in various working procedures of the process, accordingly, the investment is low, and the efficacy can be improved fast; requirements of products are mainly guaranteed by the aid of tools, the process is reasonable in arrangement, workpieces can be positioned and clamped conveniently, requirements on the precision of the workpieces can be guaranteed, and the machining efficiency is high.

Owner:SINO TRUK JINAN POWER

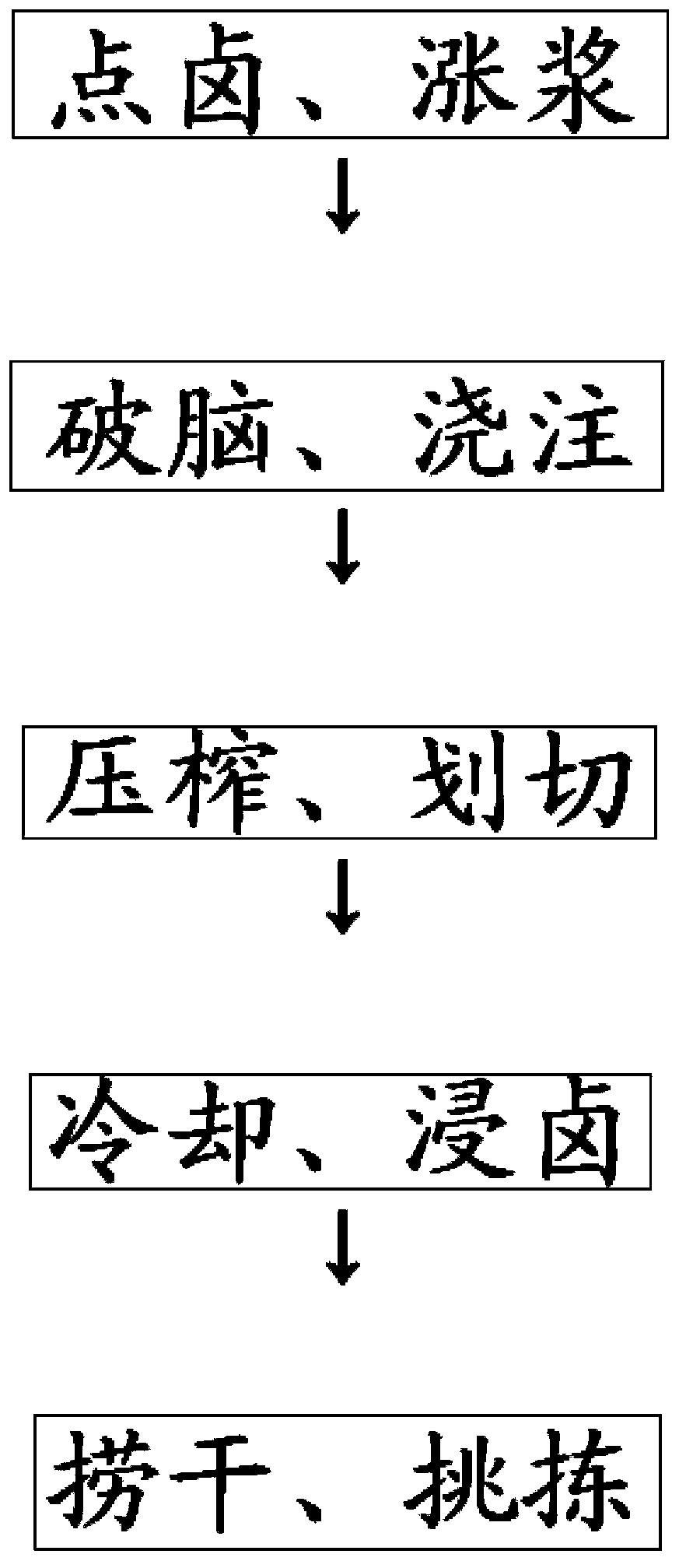

Rapid making method for stinky tofu

InactiveCN103689108ASuitable for mass productionReasonable processing technologyCheese manufactureFood scienceLarge CalorieVitamin

The invention relates to a rapid making method for stinky tofu. The main steps include: bittern dripping and static solidification, slight breaking and pouring, squeezing and cutting, cooling and brine soaking, bailing and picking, as well as casing and delivery finally. The stinky tofu made by the method provided by the invention is rich in protein, vitamin and minerals, and also contains considerable calories. Thus, the stinky tofu not only can serve as a common leisure food, but also can serve as a daily staple food, and is very suitable for people to eat out together and for work or outdoor dining. Being able to be processed into various dishes, the stinky tofu has delicate, smooth and tender taste and heavy fragrance, and is more delicious than ordinary stinky tofu. Due to a more reasonable processing technology, the product has excellent quality. The method provided by the invention has the characteristics of fast processing speed, reasonable technological arrangement, and is very suitable for mass production of food processing enterprises.

Owner:SHANGHAI QINGMEI GREEN FOOD

Atomization assisting CVD thin film deposition method

ActiveCN109440083AAdjust gas atmosphereAdjust the atmosphereLiquid/solution decomposition chemical coatingChemical vapor deposition coatingGas phaseRoom temperature

The invention discloses an atomization assisting CVD thin film deposition method. The atomization assisting CVD thin film deposition method is characterized by comprising the following steps that a, an atomization assisting CVD thin film deposition device is designed; b, a plane substrate being about to form a film is placed in an installing hole in a substrate template, then the substrate template is horizontally placed on the upper plate face of a lower lifting plate, and the position of the lower lifting plate is adjusted; d, after a temperature of a reaction area reaches a preset temperature, firstly an atomization source is opened, and is used for atomizing liquid precursors into aerosol precursors, the aerosol precursors are input into a buffering mixing chamber through carrier gas sent out of the atomization source; and e, after the temperature of the reaction area is close to a room temperature or is 45 DEG C or below, the operation that the precursors are input into the buffering mixing chamber through a gas phase matter inflow pipe and an aerosol inflow pipe firstly stops, then a gas sucking pump is closed, finally, a sealing cover is opened, the substrate template is taken out, and finally a substrate is taken down from the substrate template. The thin film deposition method is high in deposition efficiency, reasonable in process arrangement and high in thin film quality.

Owner:CHONGQING UNIV OF TECH +1

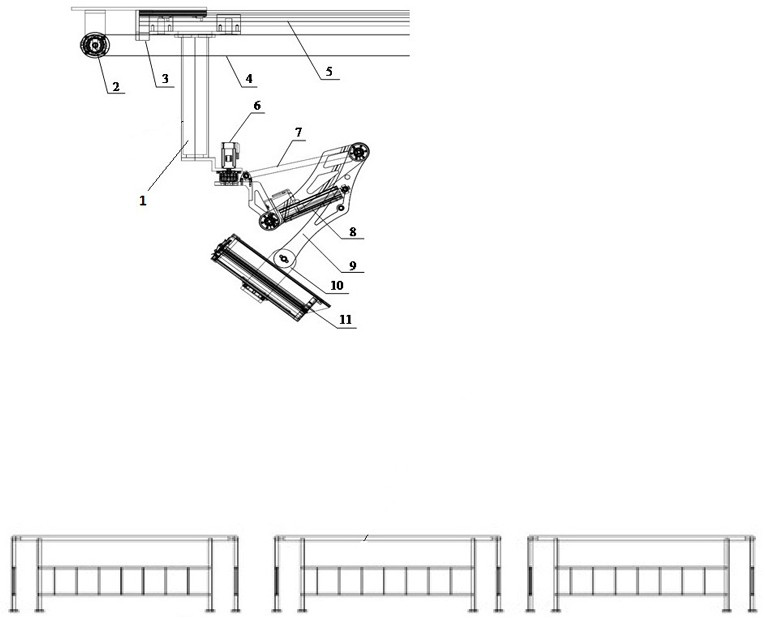

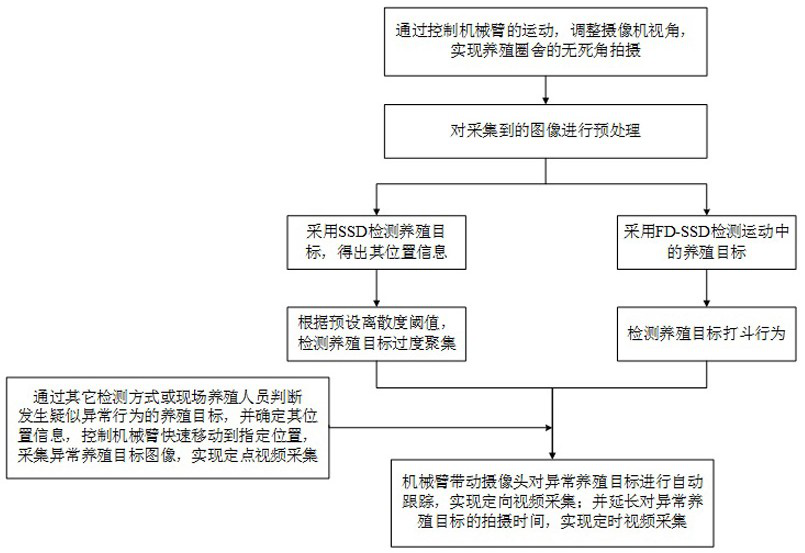

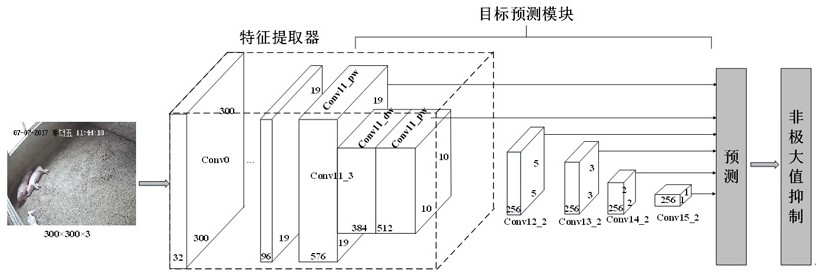

Farm target automatic tracking and monitoring video acquisition system and method

ActiveCN112598701AImprove accuracyReduce procurement costsImage enhancementTelevision system detailsAnimal scienceComputer monitoring

The invention relates to a farm target automatic tracking and monitoring video acquisition system and method. The system comprises an inspection robot and an upper computer monitoring system. A trackof the inspection robot is installed above a farm colony house, square limiting devices are arranged at the two ends of the inspection track, the mechanical arm is installed on the inspection track through a connecting rod, a camera is fixed to the other end of the mechanical arm, and the upper computer monitoring system controls the inspection robot. The method comprises the following steps: based on a breeding target detection and positioning result, controlling a mechanical arm to move, performing directional video acquisition, judging abnormal behaviors of a breeding target by an upper computer monitoring system or breeding personnel, determining a suspected abnormal behavior position, controlling a robot to move to a specified position, and performing fixed-point video acquisition. When an improved SSD detection method and an FDSSD detection method are adopted to detect that the breeding targets are excessively gathered or fight, the video collection time is prolonged, and timingvideo collection is carried out; the whole system and method are reasonable in design, easy and convenient to operate and capable of achieving real-time and automatic monitoring of breeding targets.

Owner:TAIYUAN UNIV OF TECH +1

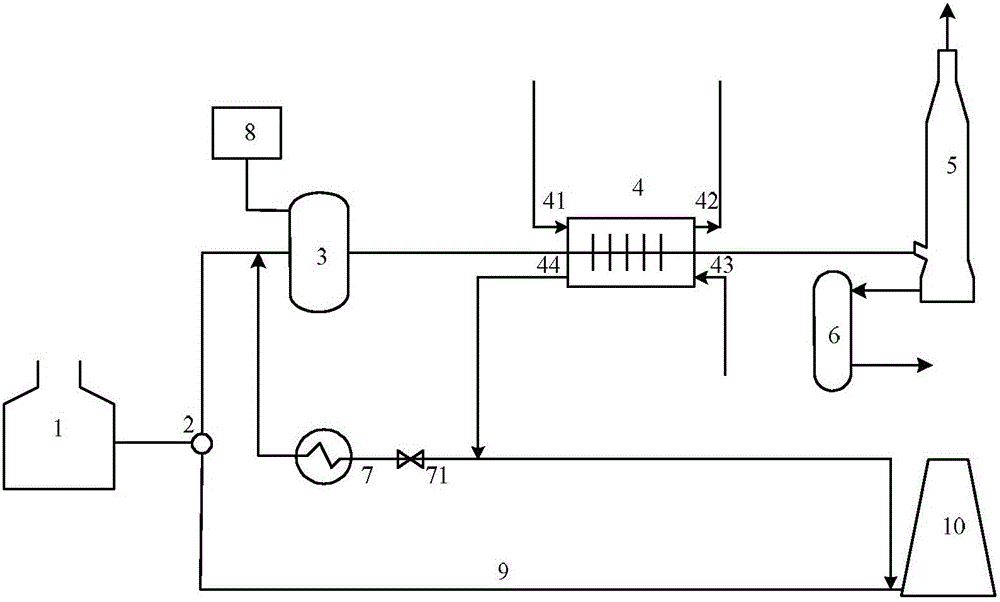

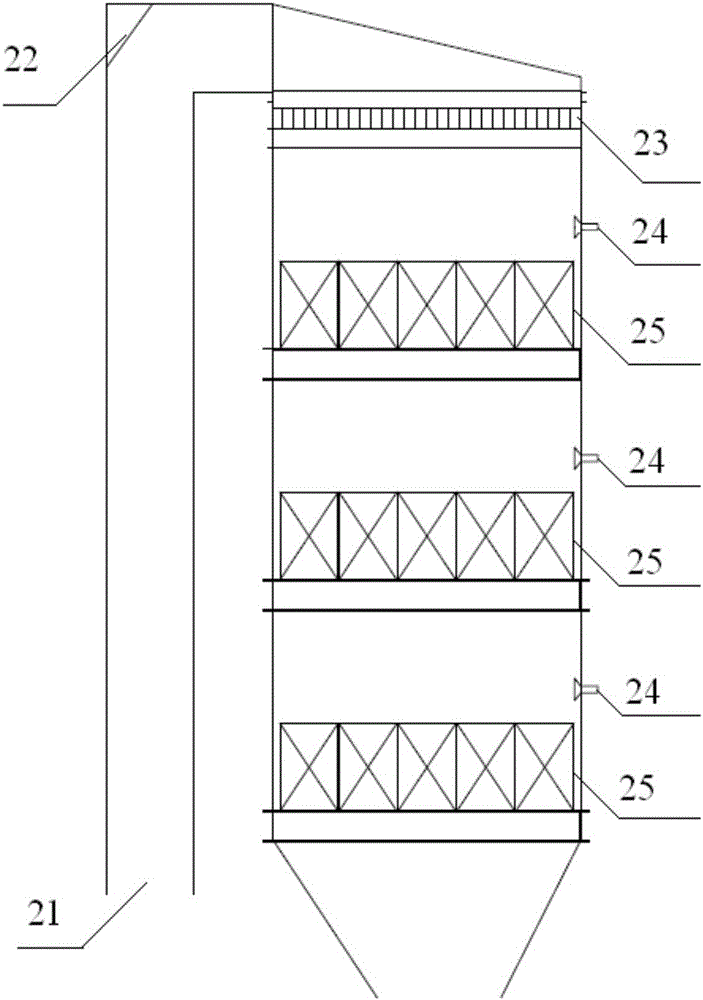

System and process for utilizing coke oven flue gas desulfurization and denitrification waste heat

InactiveCN105797581AReasonable process arrangementImprove economyGas treatmentCoke ovensSoot blowerSulfide

The invention provides a system and process for utilizing coke oven flue gas desulfurization and denitrification waste heat. The process includes: allowing flue gas to enter an SCR denitrification reactor to react with the reducing agent, allowing the flue gas after the reaction to enter a waste heat boiler module for heat exchanging, controlling the module to allow the temperature of the flue gas to be 160-180 DEG C, allowing the flue gas to enter a magnesium desulfurization module for desulfurization, and discharging, wherein the SCR denitrification reactor is connected with an inlet flue, a guide plate is arranged at the turning part of the flue, a rectifying grating is arranged on the upper portion in an SCR denitrification reactor shell, a catalyst layer is arranged below the rectifying grating, and a steam soot blower is arranged between the rectifying grating and the catalyst layer; the catalyst is a vanadium-titanium-based catalyst and / or a rare-earth-system low-temperature catalyst; volume velocity is controlled to be 5000-8000m<3> / m<3>. H, and flue gas speed is controlled to be 3-10m / s; the waste heat boiler module is a heat pipe waste heat boiler. The process has the advantages that the nitrogen oxide and sulfide in the coke oven flue gas are removed successfully, the flue gas waste heat is utilized to the maximum extent, and the economy of the system is increased.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

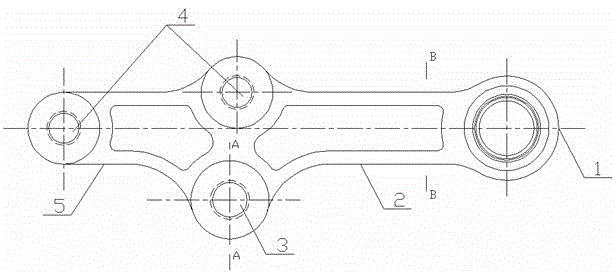

Processing technique for casting beam of automobile chassis

InactiveCN101549458AGuaranteed accuracy requirementsPrecise positioningOther manufacturing equipments/toolsEngineeringChassis

The invention relates to a processing technique for casting a beam of an automobile chassis, which comprises the following steps of: (1) milling a lower bottom surface, (2) milling an upper plane surface, (3) milling two lateral sides, (4) drilling a hole in the lower surface, (5) drilling a hole in the upper surface, (6) drilling holes at the two lateral sides, (7) boring holes at two lateral inclined surfaces, (8) milling an inner convex plate inclined surface at one side, (9) milling the inner convex plate inclined surface at the other side, (10) drilling screw holes on the inner convex plate inclined surface, (11) tapping inclined surface screw holes, (12) back facing of a hole table-board on the lower bottom surface, (13) back facing of a hole table-board on the upper plane surface and (14) back facing of hole table-boards on two lateral surfaces. The technique process has reasonable procedure arrangement, is convenient for the positioning and clamping of work pieces, and can guarantee the precision requirement of the work pieces and high processing efficiency.

Owner:SINO TRUK JINAN POWER

Process method for extracting potassium from seawater through zeolite process

InactiveCN106587248AImprove technical and economic levelEnhanced Potassium Extraction RateSeawater treatmentAlkali metal chloridesSorbentPotassium

The invention discloses a process method for extracting potassium from seawater through a zeolite process. The process method comprises the following steps that clean natural zeolite with the diameter size being 0.8 mm-2 mm is selected; the selected zeolite is boiled through saturated salt water for 2 h and remained for standby application, and the solid-liquid ratio of the zeolite to the saturated salt water is 1:10; the treated zeolite is put into reaction tanks, the seawater with the temperature being 8 DEG C-10 DEG C is uniformly sent into the reaction tanks, and the seawater passing through the reaction tanks is circularly sent into the reaction tanks again; an ammonium chloride solution with the concentration being 80%-90% is added into the reaction tanks to serve as eluents; and the solution is cooled, potassium chloride crystals are precipitated, and the residual solution is sent into the step c to be recycled. According to the process method for extracting the potassium from the seawater through the zeolite process, the natural zeolite serves as an adsorbing agent, an alkali-filtered deaminized mother solution serves as the eluents at a normal temperature, and extraction of the potassium from the seawater and combination of hot-method and alkali making are combined, so that heat consumption in potassium extraction part is reduced, the resource is wide, the cost is low, pollution is not caused, and the economical benefit is high.

Owner:广安佰瑞德钾盐化工股份有限公司

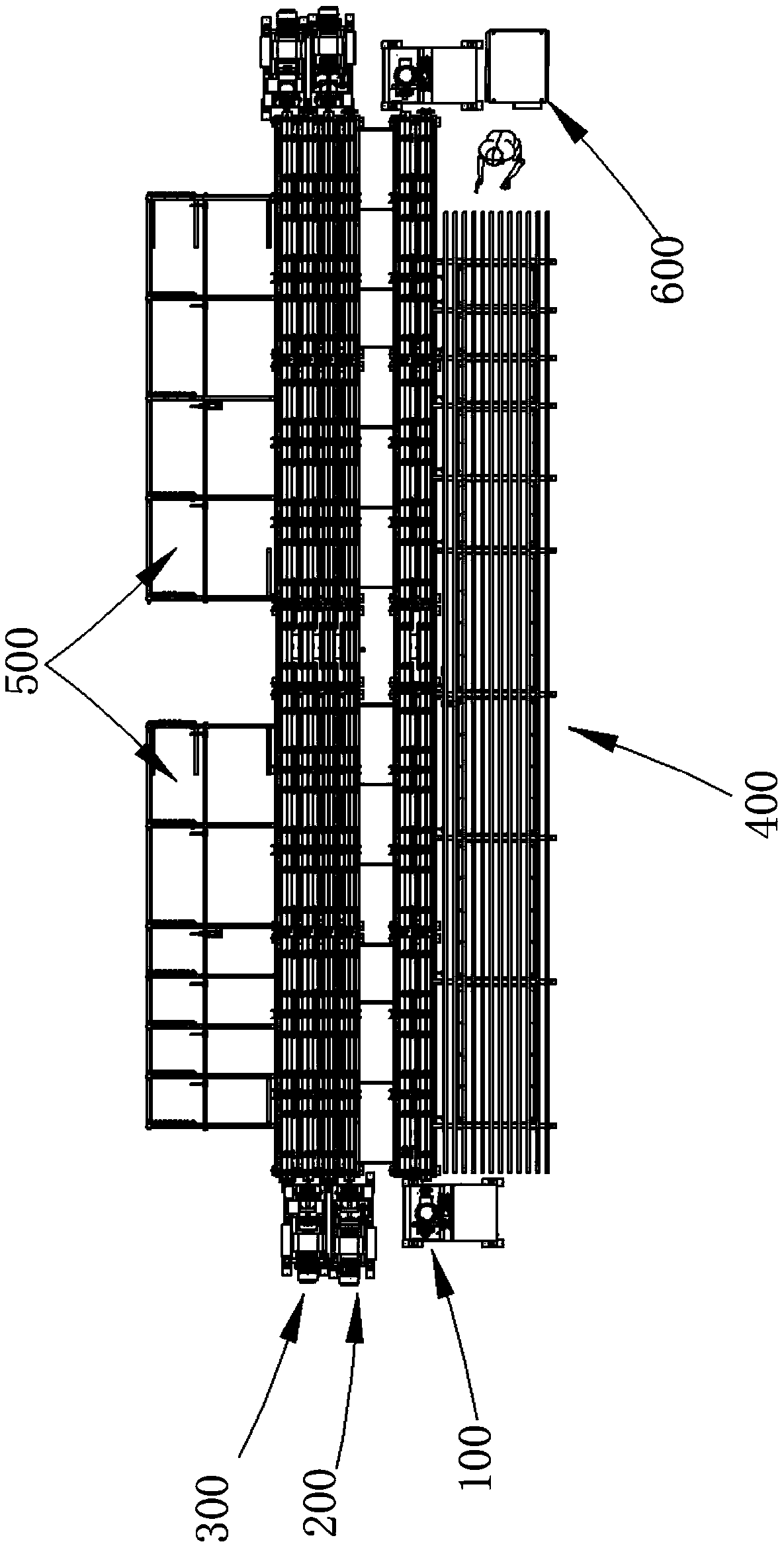

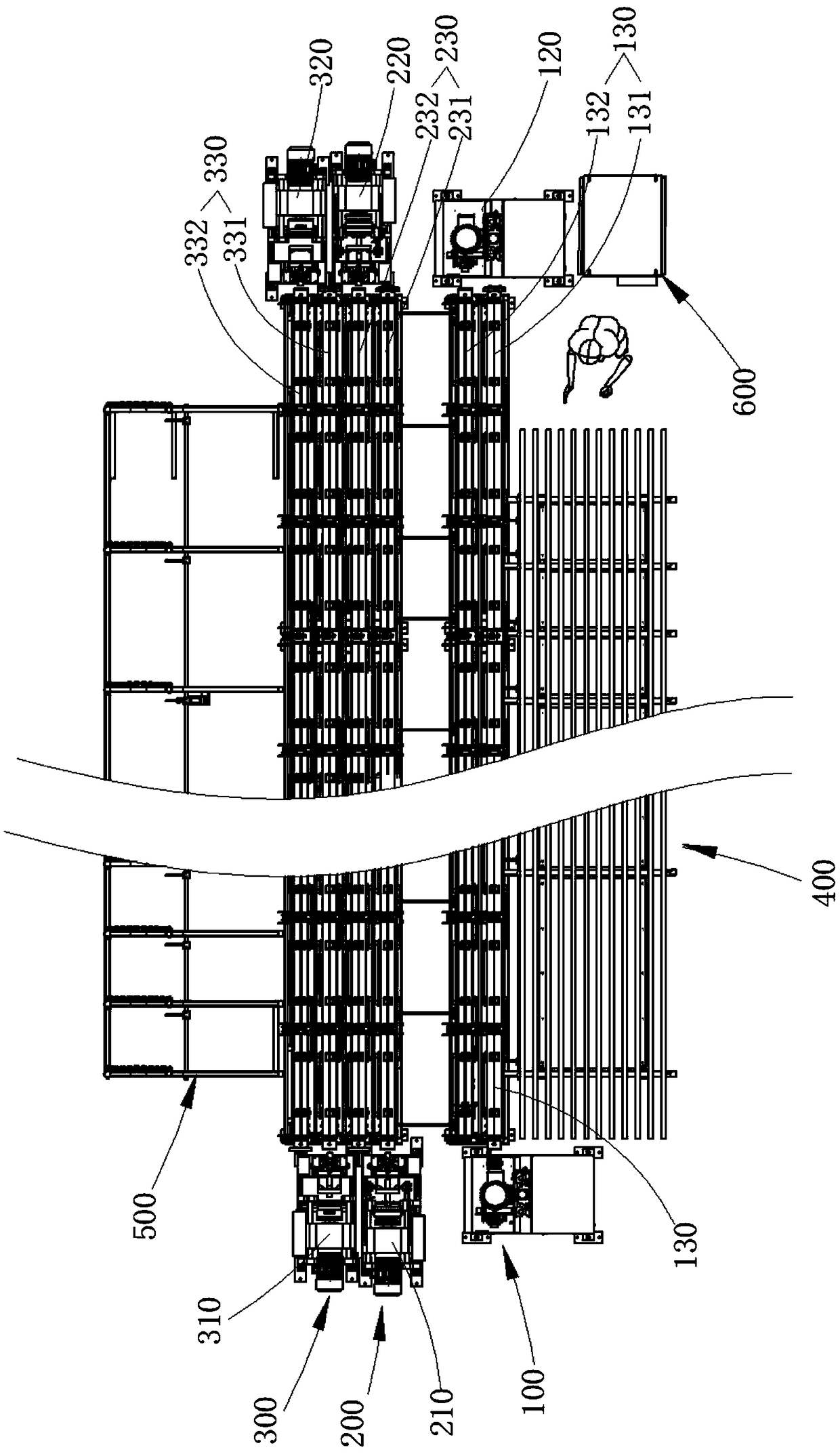

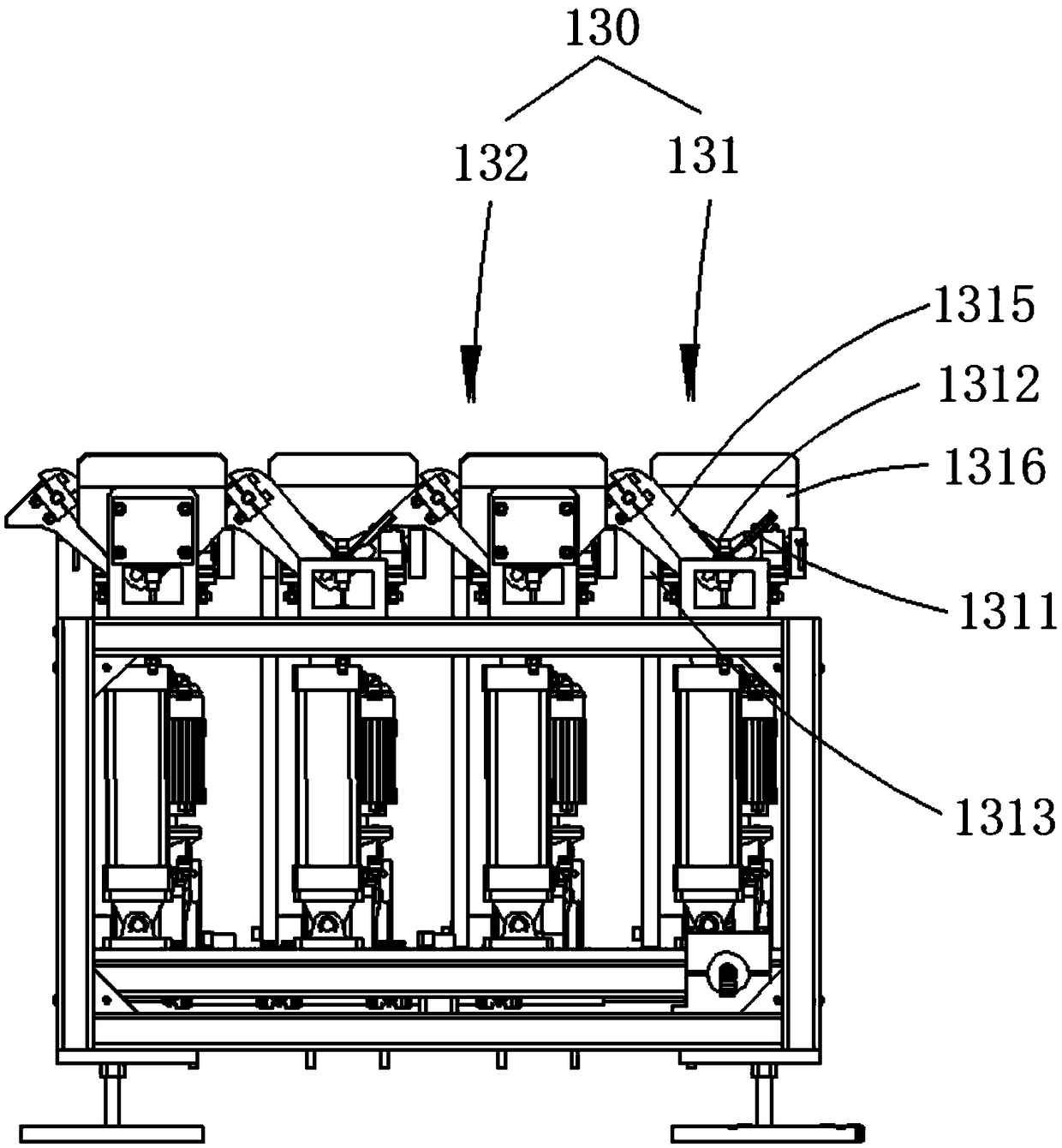

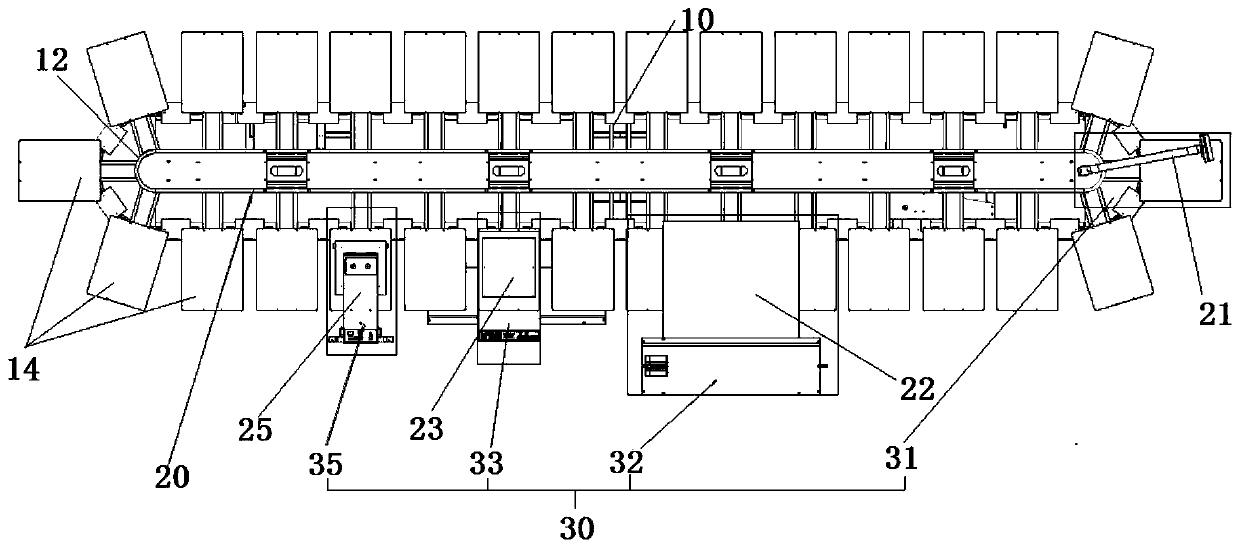

Automatic steel bar machining system

PendingCN108637372AReduce labor costsSave energyMetal sawing devicesScrew-threads articlesEngineeringRebar

The invention relates to the technical field of automatic equipment, and provides an automatic steel bar machining system. Automatic steel bar machining is achieved through a cutting module, a rib peeling chamfering module and a thread rolling module, the labor cost can be saved, and the production efficiency is improved, wherein the cutting module, the rib peeling chamfering module and the threadrolling module are sequentially arranged. The machining modules are arranged in a modular combination manner. Through the arrangement of procedures of saw cutting, rib peeling chamfering and thread rolling, the technical problem that in the prior art, a flat end face formed after saw cutting deforms after rib peeling and thread chaing, and rubbing-down needs to be conducted again is solved, the grinding procedure is omitted, technology arrangement is more reasonable and simpler, the problem about the large occupied area is solved, and energy saving and consumable reduction are facilitated. Rib peeling chamfering machining and thread rolling machining are divided into two procedures, the problem that in the prior art, the machining duration of rib peeling and thread rolling machining and grinding machining is not matched with the saw cutting machining duration beat is solved, technology arrangement and the production beat are more reasonable, and the production efficiency can be betterimproved.

Owner:康振智能装备(深圳)股份有限公司

Instant chicken soup rice and fried rice and making methods thereof

The invention belongs to the technical field of food processing, and particularly relates to instant chicken soup rice and fried rice and making methods thereof. The instant chicken soup rice is composed of 74-80% of rice grain, 2-5% of diced chicken, 2-4% of cabbage, 1.5-3% of edible textured soybean protein powder, 1.5-2.5% of diced mushroom, 1-3% of diced carrot, 0.3-2.5% of chive, 3-6% of smashed potato powder, 3-5% of chicken essence powder, 2-6% of soup essence, 0.5-1.5% of hen flavor powder, 0.4-0.6% of thirteen spice and 0.006-0.01% of vinegar powder. The instant chicken fried rice is composed of 82-88% of rice grain, 8-12% of diced chicken, 1.5-2.5% of diced mushroom and 0.3-2.5% of chive.

Owner:DAQING ZHOUJIAZHUANG FOOD CO LTD

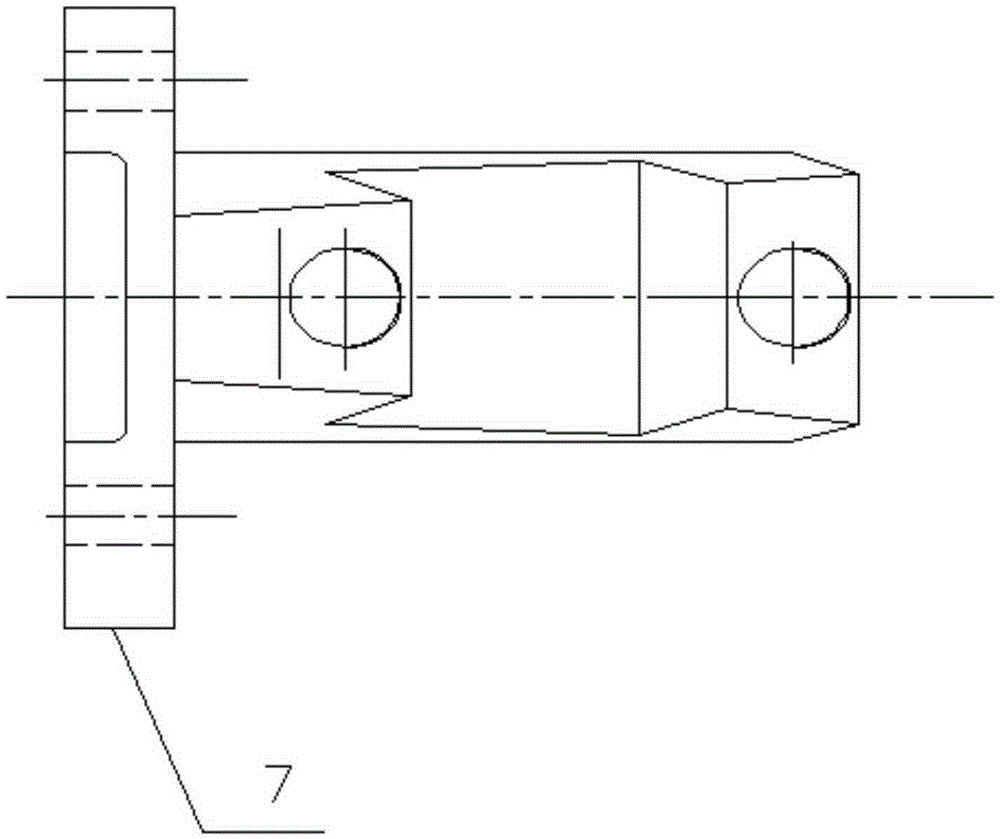

Processing technology of left support and right support of novel suspension V-shaped propelling rod of heavy automobile

ActiveCN103522010AGuaranteed accuracy requirementsPrecise positioningPivoted suspension armsEngineeringMachine tool

The invention provides a technical scheme of a processing technology of a left support and a right support of a novel suspension V-shaped propelling rod of a heavy automobile. According to the technical scheme, the processing technology comprises the first step of milling a lower side face, the second step of milling a bottom face, the third step of drilling 14 bolt connecting holes and drilling and reaming 2 technological positioning holes, the fourth step of milling a boss inclined face on one side, the fifth step of milling a boss inclined face on the other side, the sixth step of drilling a boss inclined face thread bottom hole in one side, the seventh step of drilling a side boss inclined face thread bottom hole in the other side, the eighth step of tapping a boss inclined face thread hole, and the ninth step of using a counter bit for reaming platform tops of all holes in the bottom face with the bottom face 1 and the side face 7 used for positioning and a positioning circular hole used for auxiliary positioning. According to the processing technology, processing can be carried out on different machine tools according to different procedures, investment is low, and synergy is fast. The requirement of a product is guaranteed mainly through a tool, the technology arrangement is reasonable, a workpiece is positioned and tightly clamped conveniently, the requirement for the precision of the workpiece can be ensured, and processing efficiency is high.

Owner:SINO TRUK JINAN POWER

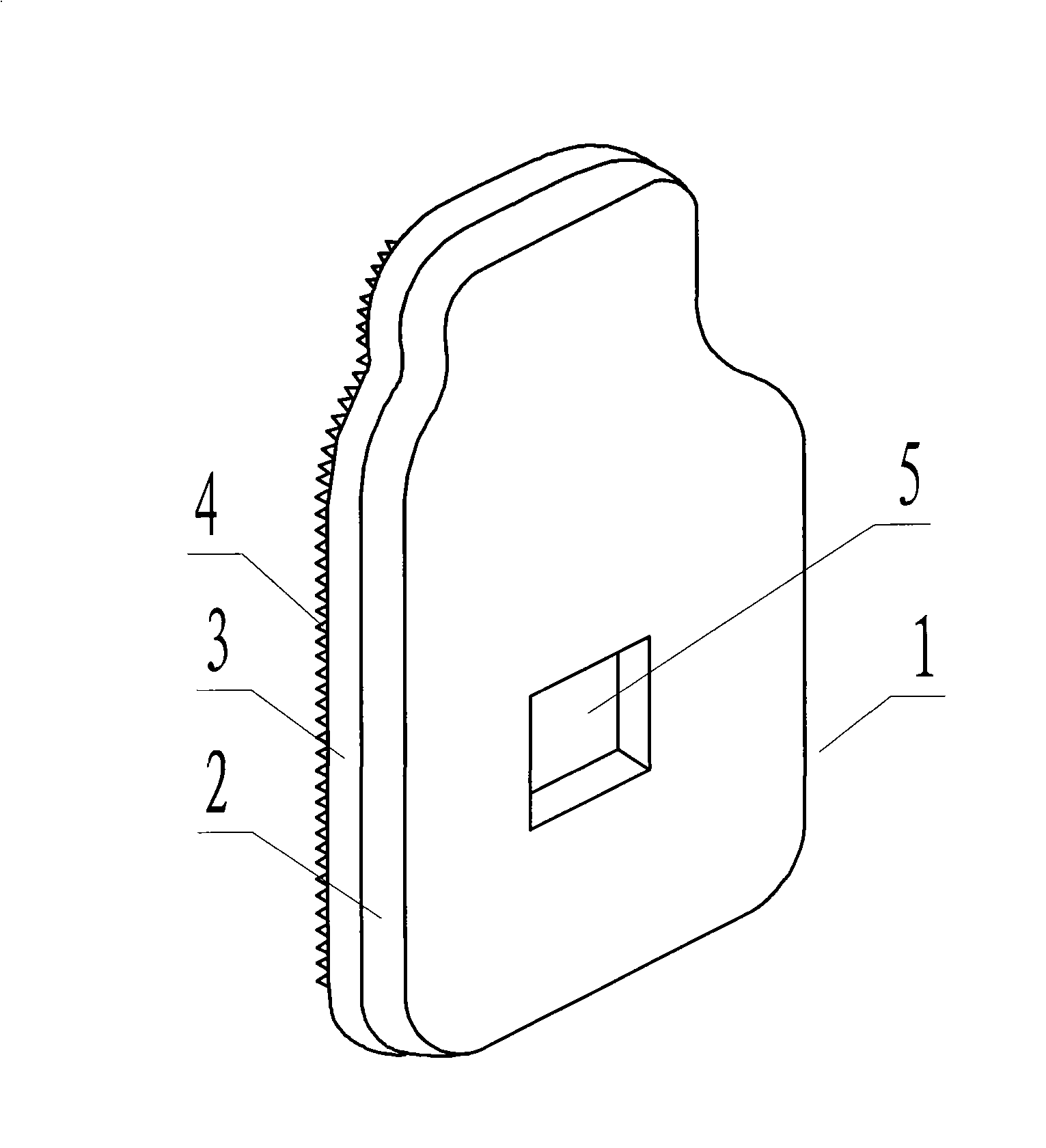

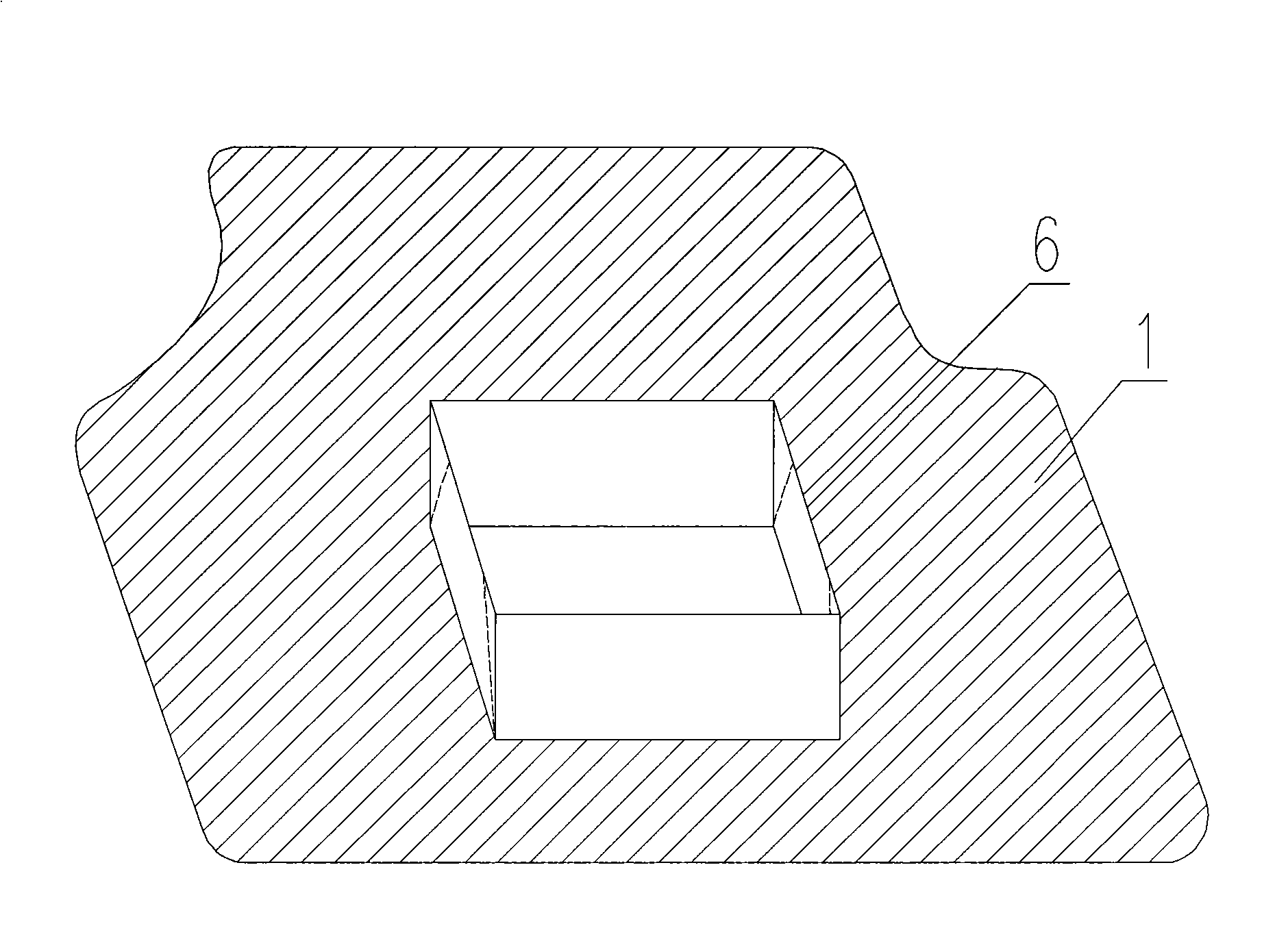

Vehicle pad with groove and manufacture method thereof

InactiveCN101327757ASimple preparation processReasonable process arrangementBack restsThigh restsMarine engineeringCushion

The invention provides a vehicle cushion with a groove and a manufacturing method thereof, specifically a cushion with a grove for automobile and a manufacturing method thereof. A vehicle cushion with a groove of the invention, a groove with depth not less than one third of thickness of the vehicle cushion is on the front face of the vehicle cushion. The invention aims to solve the problem to manufacture one or more grooves with various forms and a greater depth, or penetrating up and down on the vehicle cushion. The manufacturing method of the vehicle cushion with a groove has rational technology, simple and reliable process, with high production efficiency and low cost. The invention further provides a receiving container to be installed inside the groove thereof, with deft design, and good adhesion to the vehicle cushion, which can be integrated with the cushion when being folded with good looking.

Owner:格兰特杨

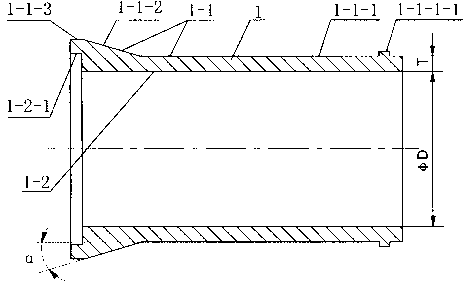

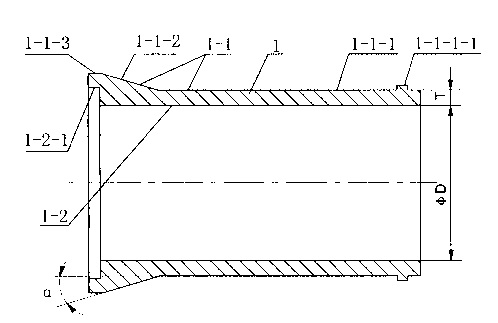

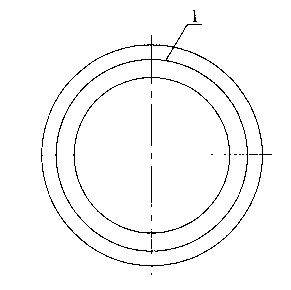

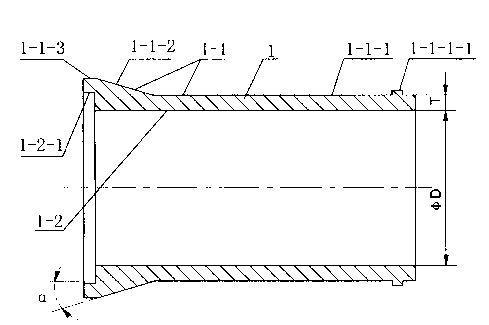

Novel grooving discharge pipe used for installation

The invention relates to a discharge pipe, in particular to a novel grooving discharge pipe used for installation. The novel grooving discharge pipe used for the installation is composed of a water pipe body (1), wherein the cross section of the water pipe body (1) is ring-shaped, and the water pipe body (1) comprises a pipe outer diameter (1-1) and a pipe inner diameter (1-2). The pipe outer diameter (1-1) is composed of a small outer diameter face (1-1-1), an inclined plane (1-1-2) and a large outer diameter face (1-1-3). One end of the small outer diameter face (1-1-1) is connected with the large outer diameter face (1-1-3) through the inclined plane (1-1-2), the included angle between the inclined plane (1-1-2) and the horizontal plane is 15 degrees, an annular boss (1-1-1-1) is arranged at the other end of the small outer diameter face (1-1-1), and an annular groove (1-2-1) is arranged at one end of the pipe inner diameter (1-2). According to the novel grooving discharge pipe used for the installation, a flange-type structure is formed to avoid leakage, the novel grooving discharge pipe used for the installation is reliable in sealing, good in tightness and reliability, moreover simple in structure and low in manufacturing cost.

Owner:溧阳市保珠建材厂

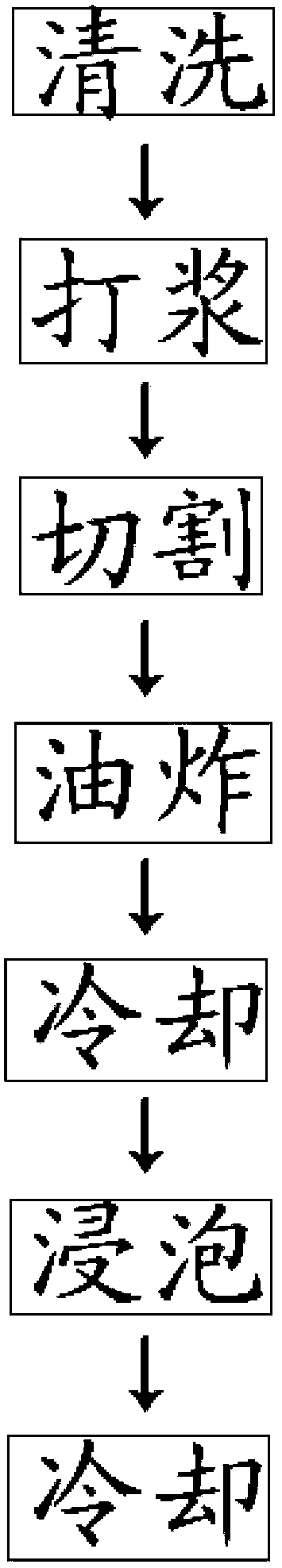

Rapid manufacturing method of fried gluten puff

InactiveCN103098975AFast processingReasonable process arrangementVegetable proteins working-upGlutenRapid manufacturing

The invention discloses a rapid manufacturing method of fried gluten puff. The method comprises the following steps of: cleaning, pulping, cutting, frying, cooling, soaking and cooling. The fried gluten puff manufactured by the method is high in processing speed, reasonable in technical arrangement, and very suitable for batch production of food processing enterprises, and the production procedure is simplified.

Owner:SHANGHAI QINGMEI GREEN FOOD

Surface printing machine and surface printing process

InactiveCN111016413AReduce manual operationsIncrease productivityScreen printersTypewritersTextile printerAutomatic control

The invention relates to a surface printing machine and a surface printing process. The surface printing machine comprises a rack, a printing mechanism, a driving mechanism and a control mechanism, wherein the rack comprises an annular guide rail and a plurality of printing and dyeing stations slidably arranged on the annular guide rail; and the printing and dyeing station circularly slides on theannular guide rail under the driving of the driving mechanism and sequentially passes through a plurality of functional areas to complete corresponding process operation. According to the surface printing machine, the annular guide rail and the printing and dyeing station are arranged, scraping printing equipment and spraying printing equipment which are required in the printing process are arranged on the annular guide rail, the control mechanism controls the driving mechanism to work, the printing and dyeing station is driven to circularly slide on the annular guide rail, related process steps are completed on the corresponding printing mechanism, manual operation is reduced by automatic control, the production efficiency is improved, the process arrangement is reasonable, the operation is simple, and the printing effect is good.

Owner:广州诚鼎机器人有限公司

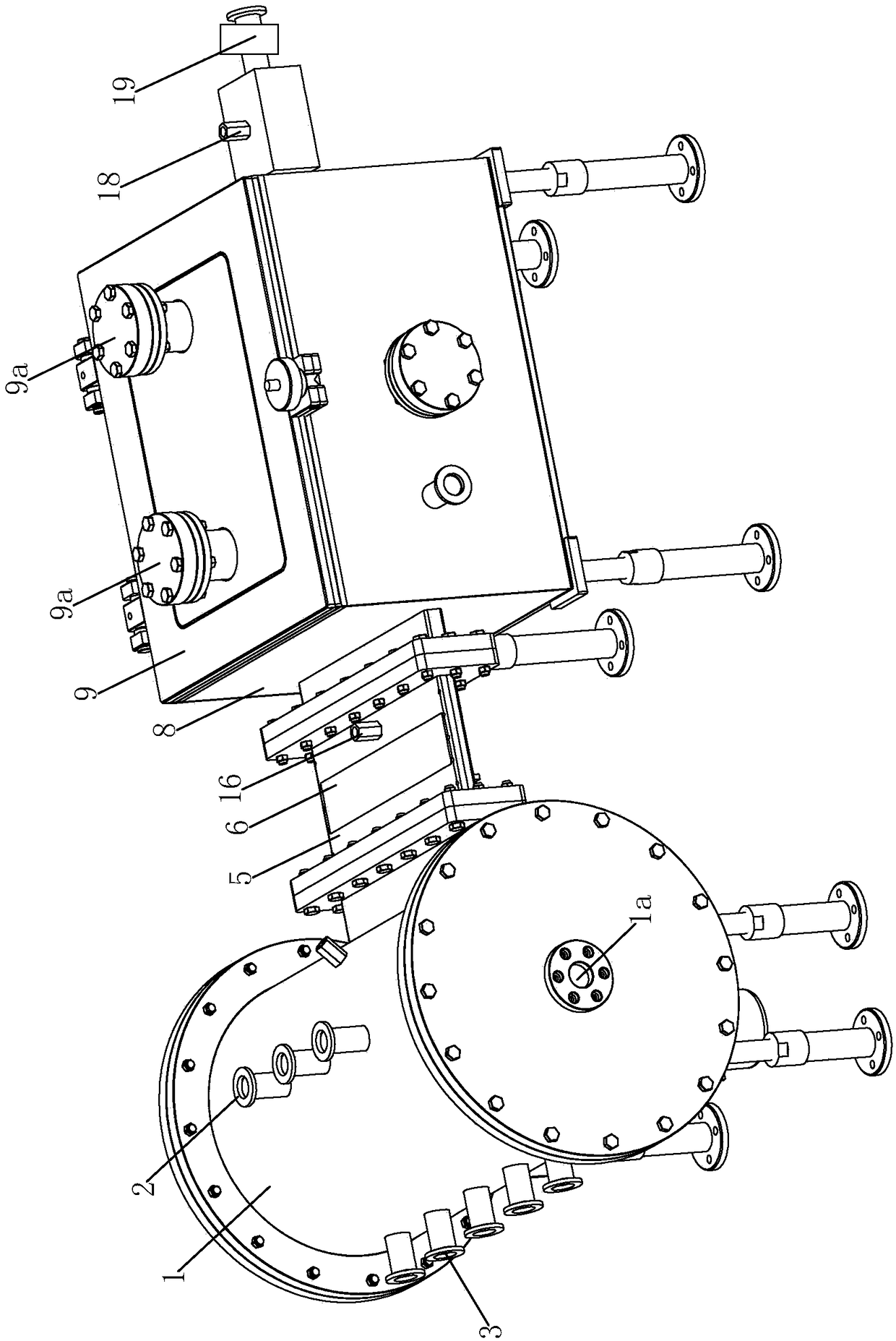

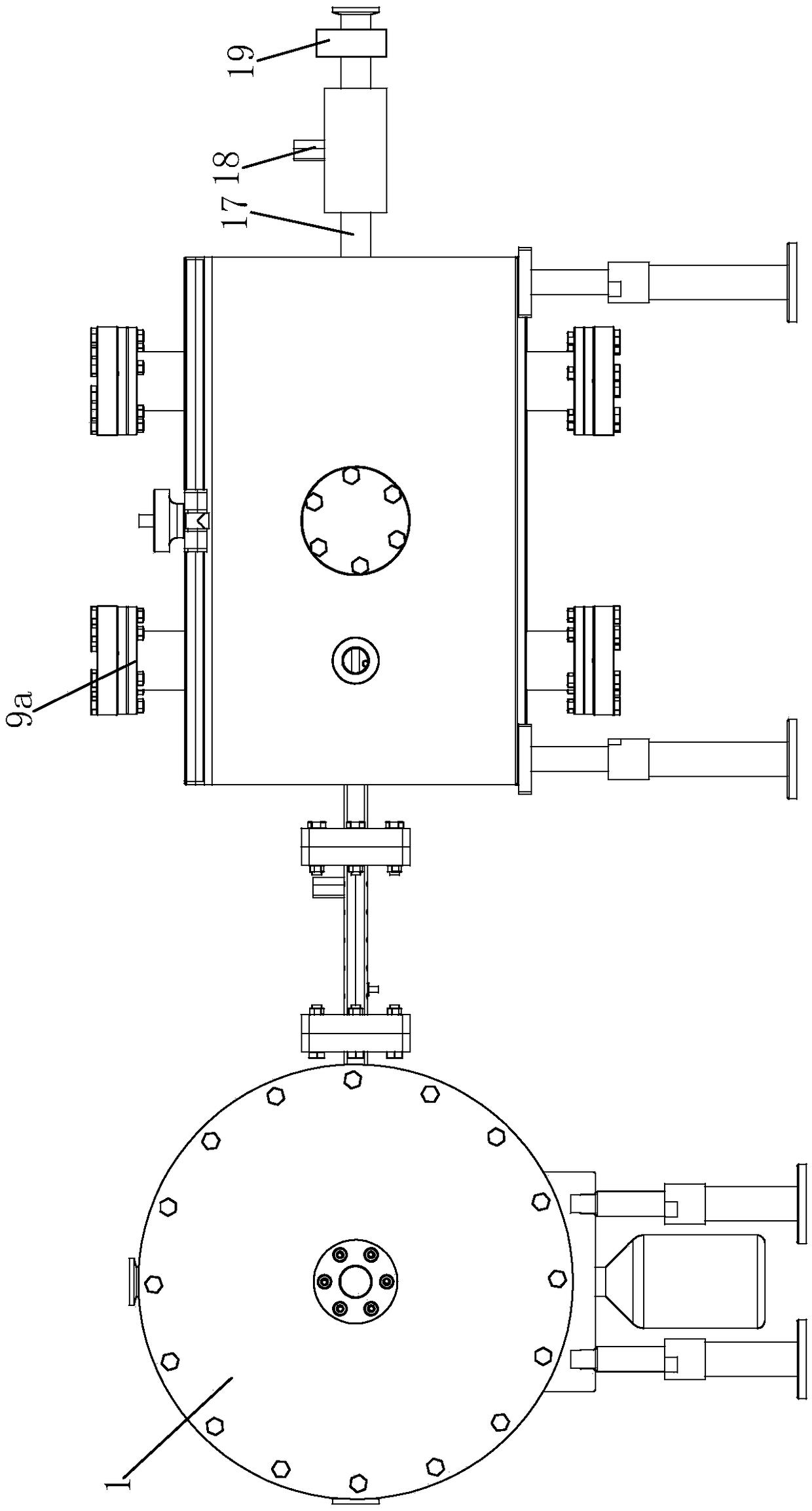

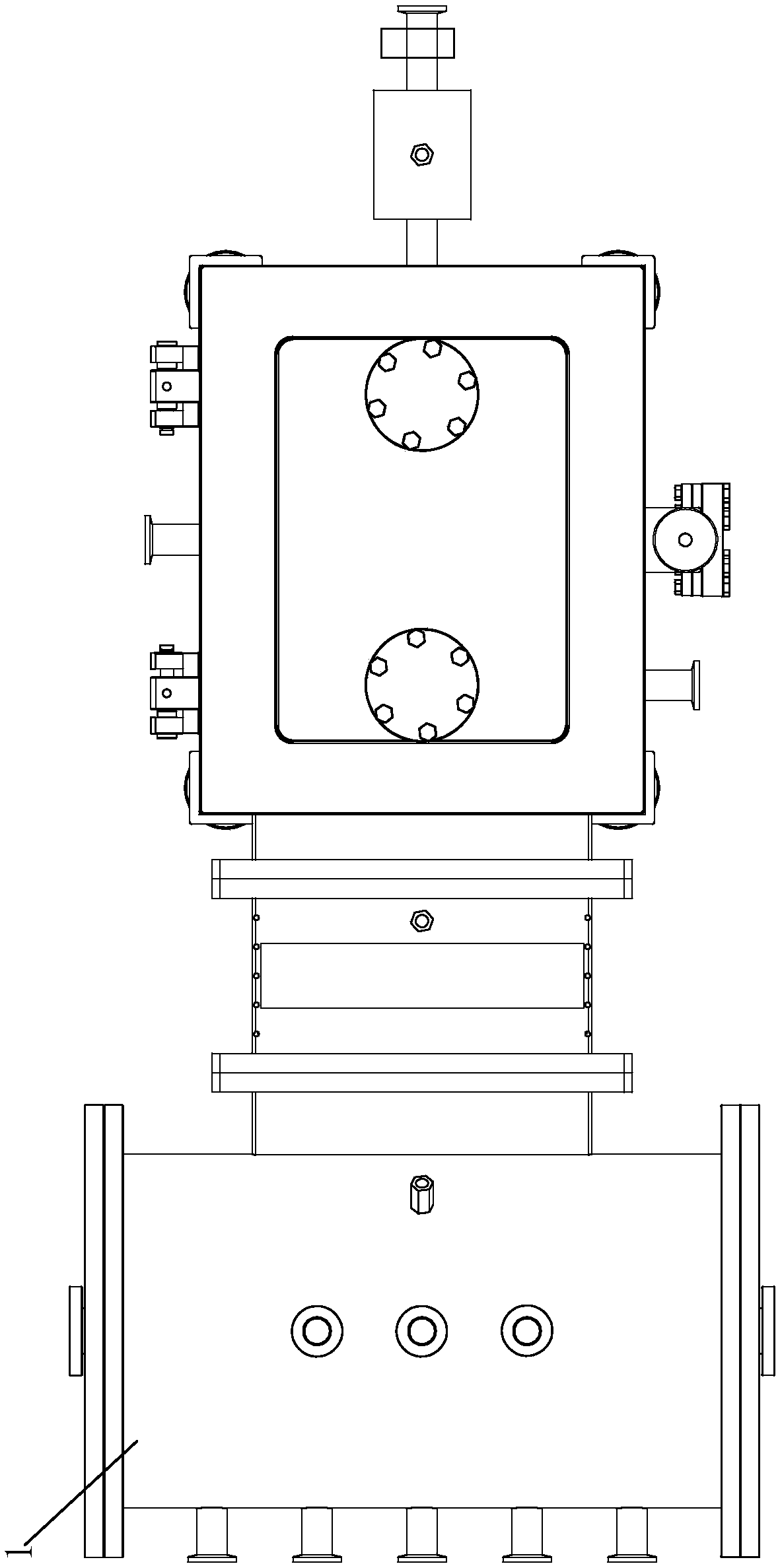

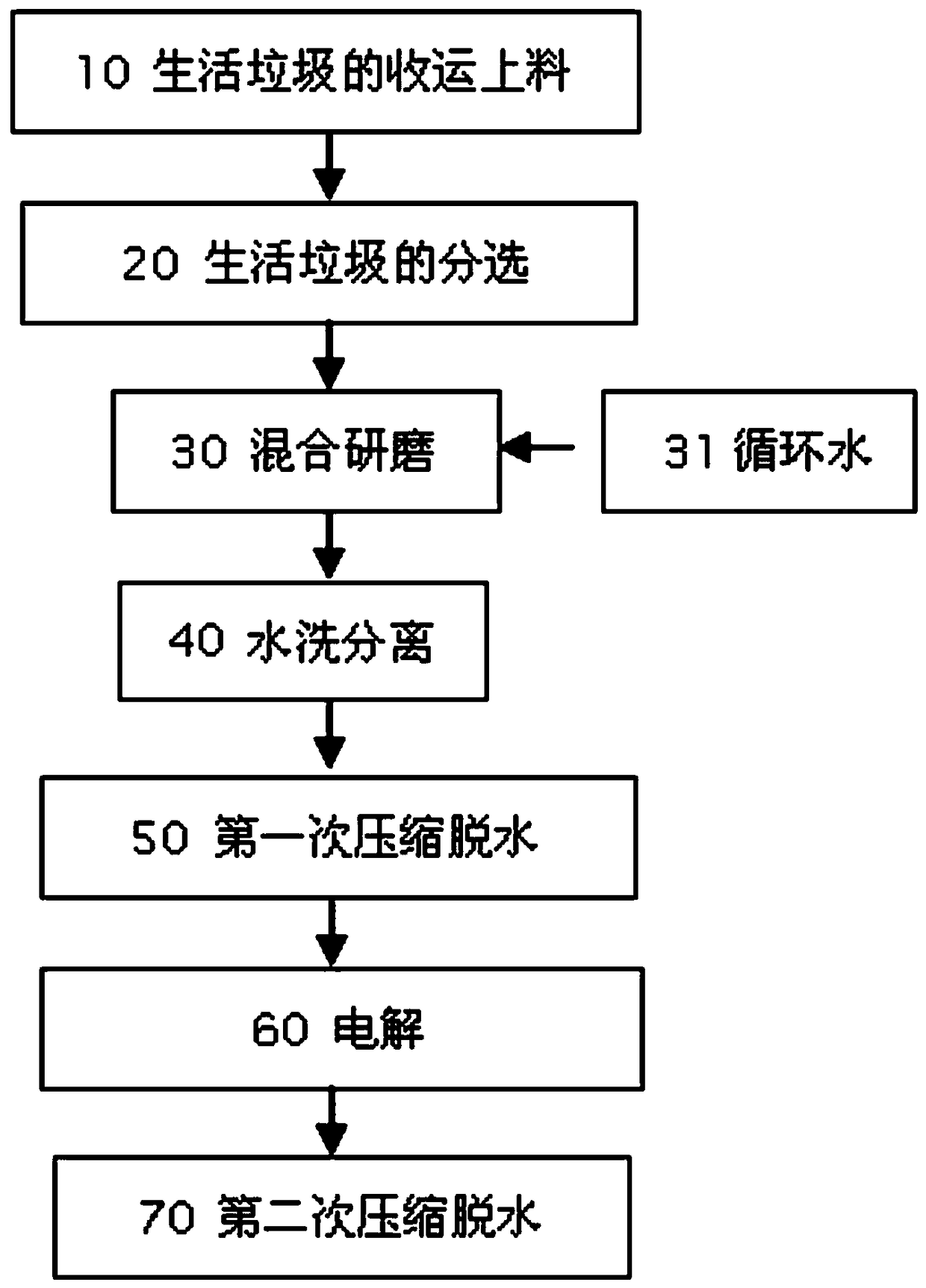

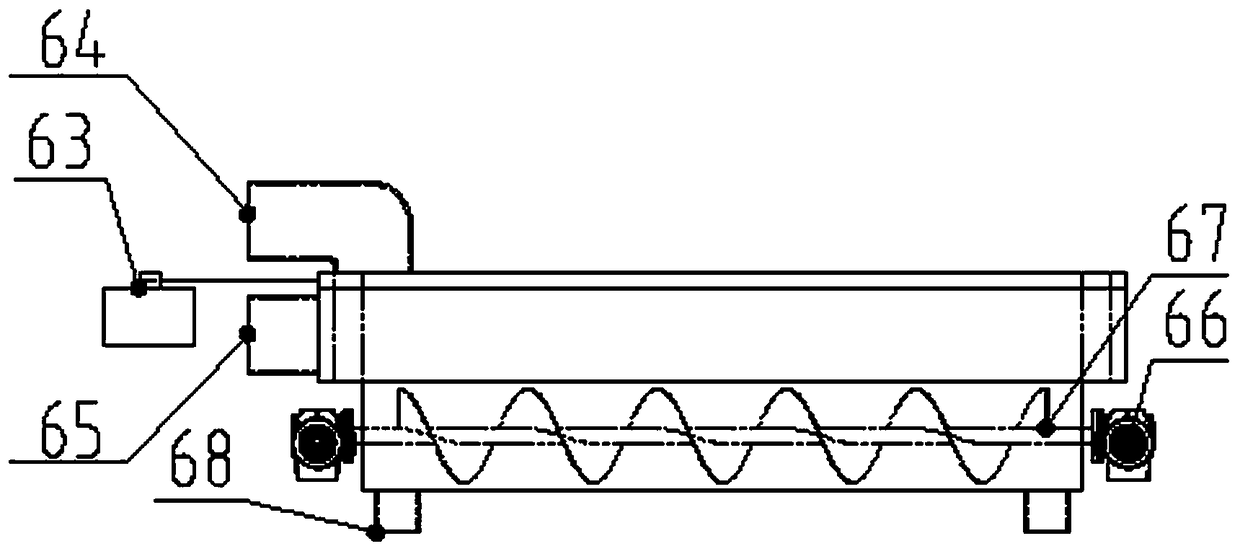

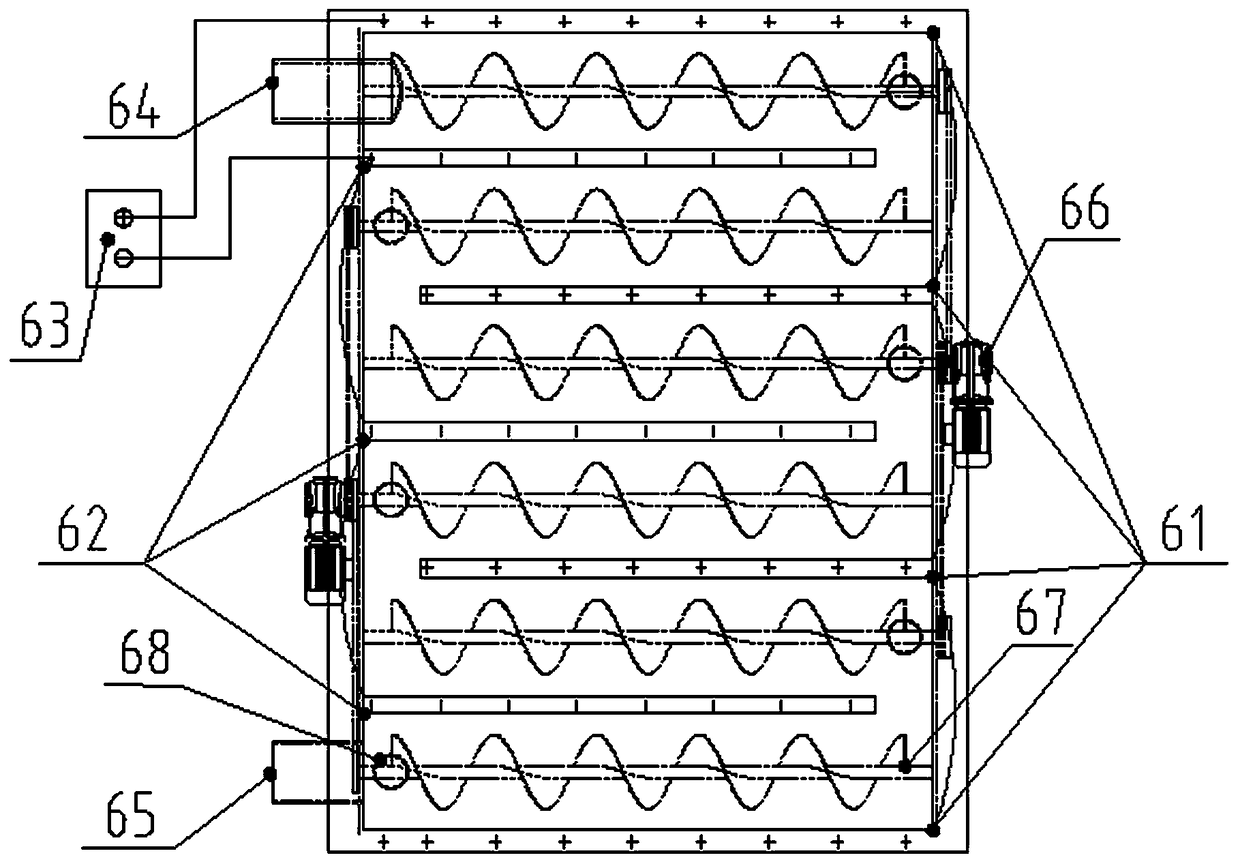

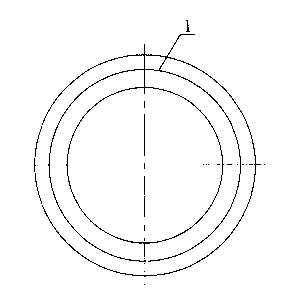

Process and electrolysis device for removing heavy metals in domestic garbage organic waste

ActiveCN106238441BMeet production needsEliminate polluted environmentPhotography auxillary processesSolid waste disposalChemical treatmentElectrolysis

The invention discloses a process and an electrolyzer for removing heavy metal in organic waste in household garbage. The process comprises seven processes which are sequentially as follows: collecting, transporting and loading of household garbage, sorting of household garbage, mixing and grinding, washing and separating, primary compressing and dehydrating, electrolyzing, and secondary compressing and dehydrating. By virtue of the processes, the household garbage is treated into compost raw materials. The electrolyzer comprises a box body, a positive electrode guide plate, a negative electrode guide plate, a rod type spiral pusher, a speed reducer, a charge tube, a discharge tube and a precipitate discharge hole. The process is scientific in conception, eliminates the problem that environment is polluted by heavy metal due to the fact that organic waste in household garbage is used for composting, saves operation cost in comparison with other physical or chemical treatment methods, improves compost fertilizer efficiency, is stable in operation, and is simple and convenient to operate.

Owner:BEIJING ZHENGSHI ENVIRONMENTAL PROTECTION ENG CO LTD

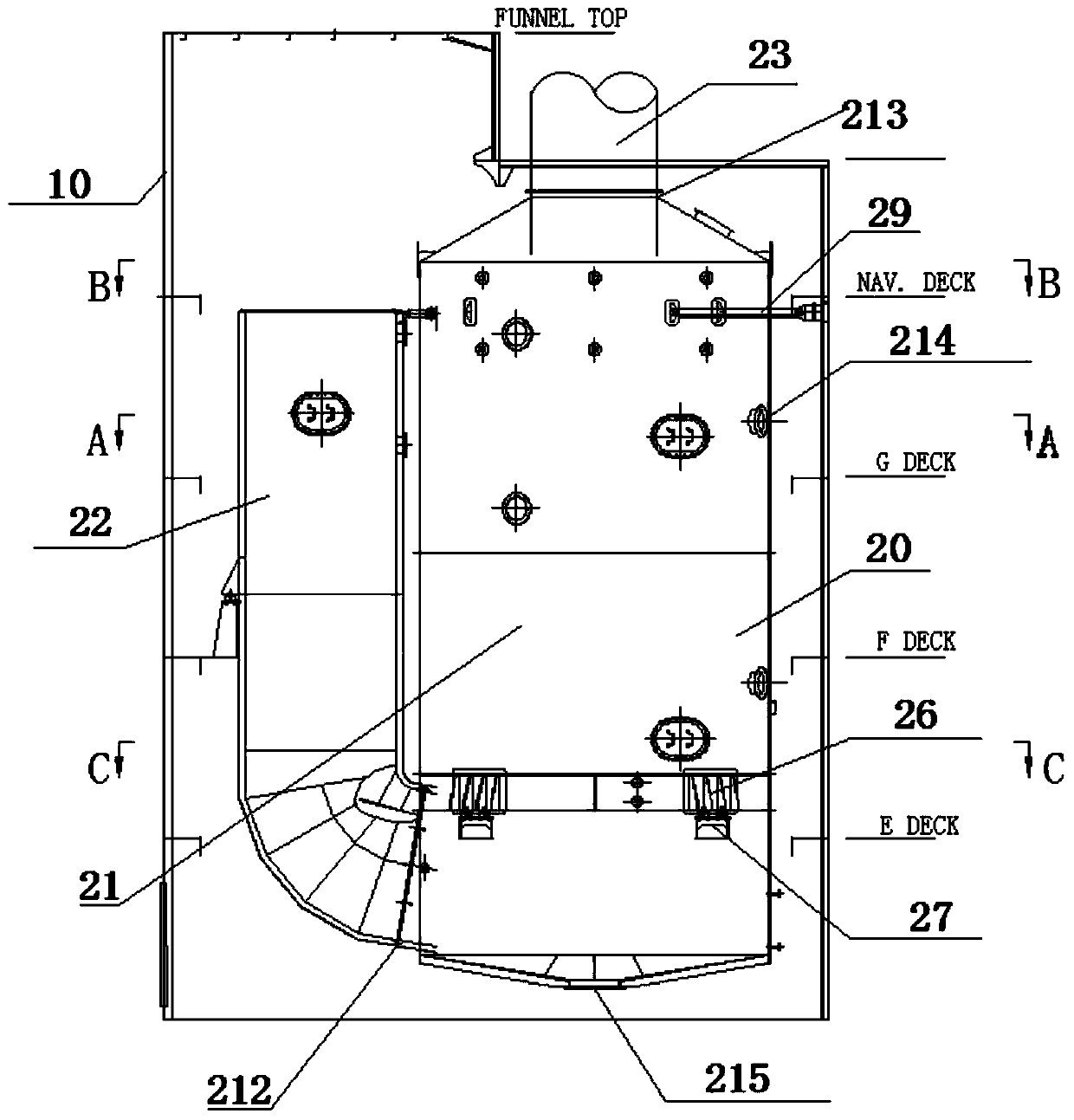

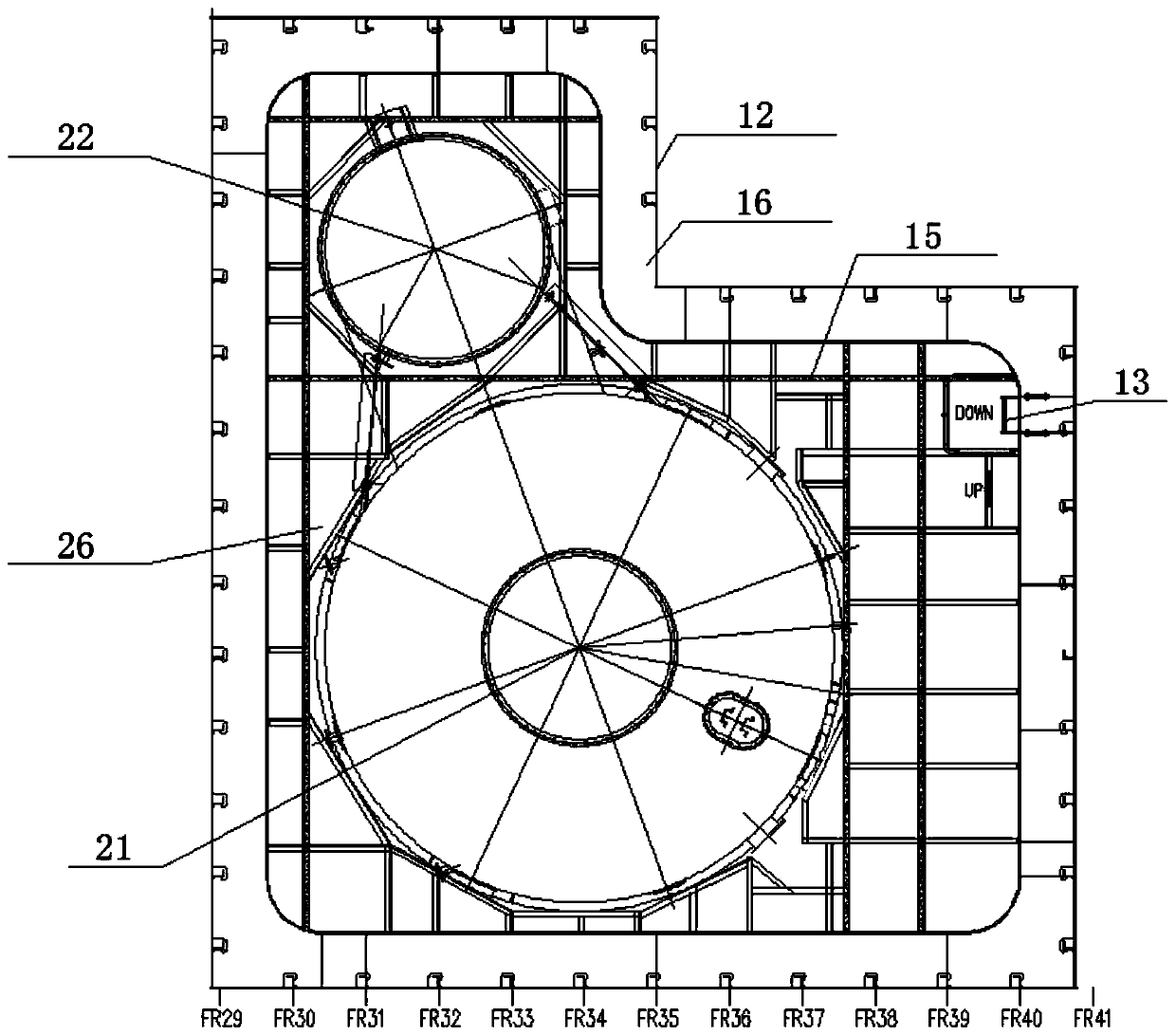

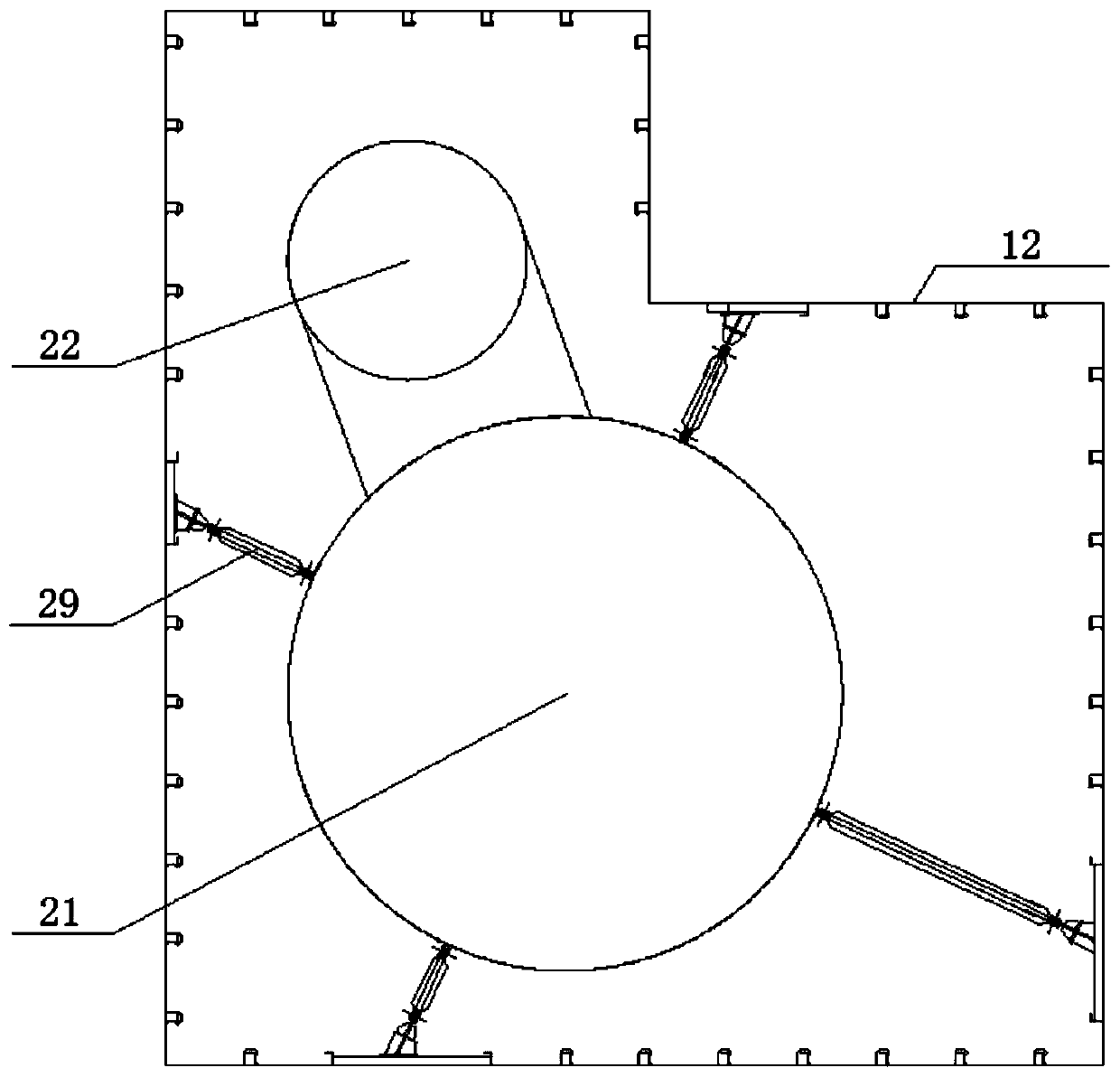

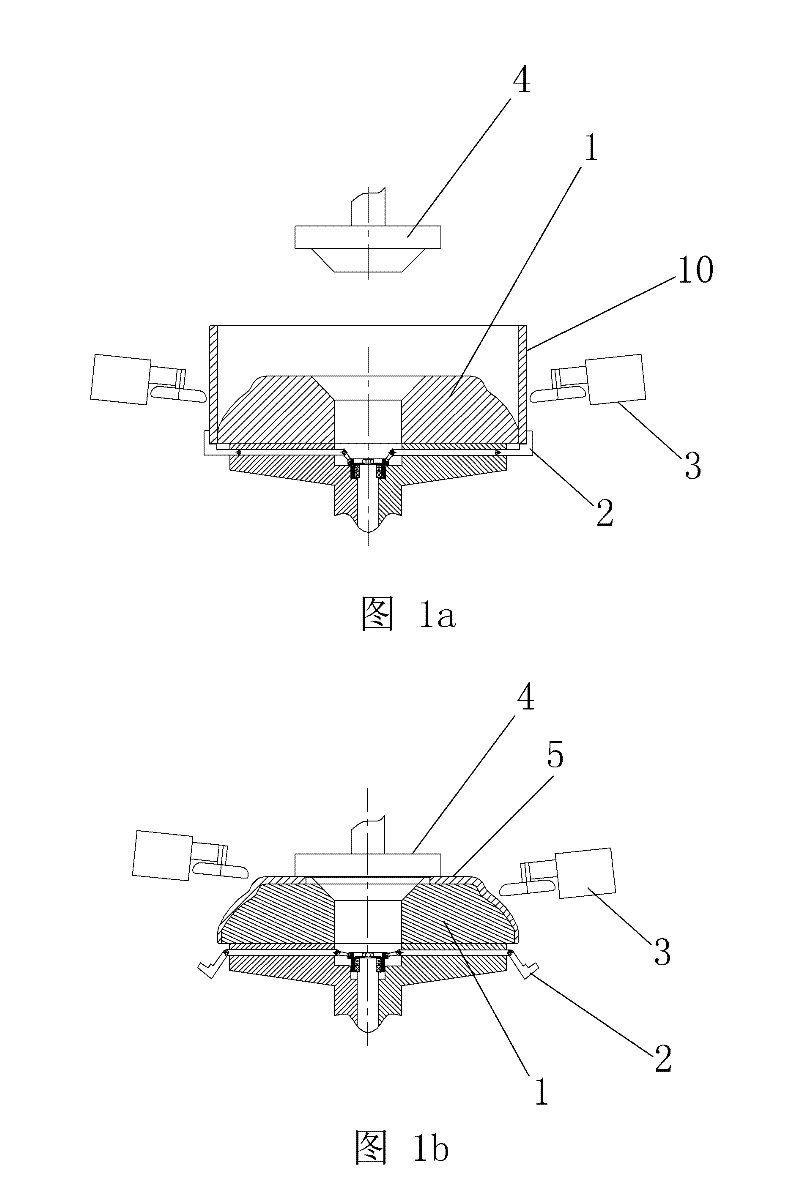

Desulfurization chimney and manufacturing and mounting method thereof

InactiveCN111495153AAvoid collisionNormal operation is not affectedPropulsion power plantsDispersed particle separationButt jointProcess engineering

The invention relates to a desulfurization chimney and a manufacturing and mounting method thereof. The desulfurization chimney comprises a chimney assembly and a desulfurization device arranged in the chimney assembly, the desulfurization device assembly is integrally arranged in the chimney assembly. The device arrangement is reasonable; the modularized design degree is high; and during ship desulfurization and installation, only the desulfurization chimney needs to serve as an independent unit to be hoisted onto a ship, and the pipeline connector of a desulfurization tower accessory is connected with the exhaust pipelines of a main engine and an auxiliary engine of an original ship to form a set of recyclable desulfurization system, so that the workload of dismounting or refitting the original ship is greatly reduced, the construction period is favorably shortened, and the refitting cost is saved. The manufacturing and mounting method is reasonable in process arrangement and convenient to operate, and device damage is not prone to occurring in the mounting process; good butt joint of the desulfurization chimney and an original ship structure can be guaranteed through positioningof the desulfurization tower and the desulfurization tower base, so the structural stability and the structural strength are high, and it is guaranteed that normal operation of the desulfurization tower is not affected.

Owner:广州文冲船舶修造有限公司

A coating process for the middle beam frame of a loader

InactiveCN104324871BExtended service lifeProtectPretreated surfacesUnderstructuresEngineeringIron Black

The invention provides a process for coating a middle beam frame of a loading machine. After a middle beam frame structure is connected, the specific spraying process is as follows: deoiling; derusting; cleaning; priming; drying; polishing; scouring; performing topcoating: diluting black vinyl perchloride enamel, air-drying bituminous enamel or magnetized iron black hydroxyacid finish coat until the viscocity is applicable to construction, and then spraying the frame for once, wherein in order to obtain a vinyl perchloride enamel film with relatively large thickness, the black vinyl perchloride enamel is firstly sprayed for a thin pass and is uniformly sprayed for once after 20 minutes; drying, namely drying bituminous enamel and hydroxyacid finish coat for 24 hours and drying vinyl perchloride enamel for 6-8 hours. The process for coating the middle beam frame of the loading machine is reasonable in process arrangement and is capable of ensuring that the middle beam frame is well protected by coatings and prolonging the service life of the middle beam frame.

Owner:张永

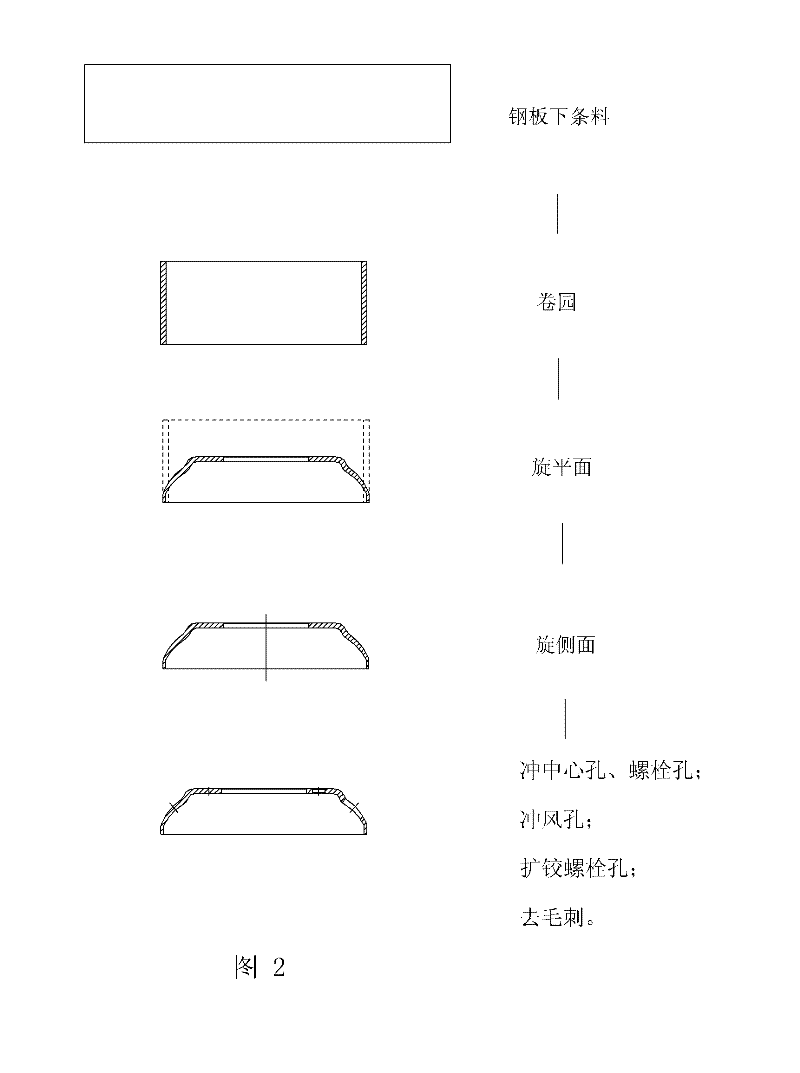

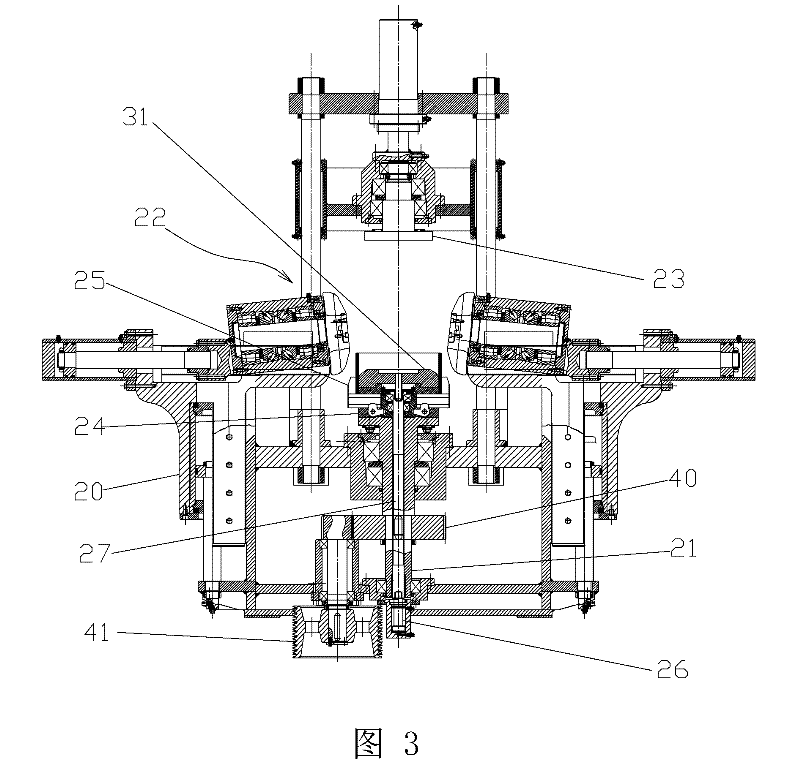

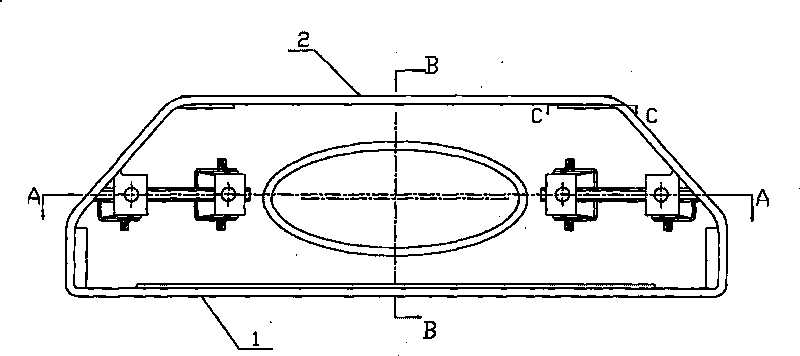

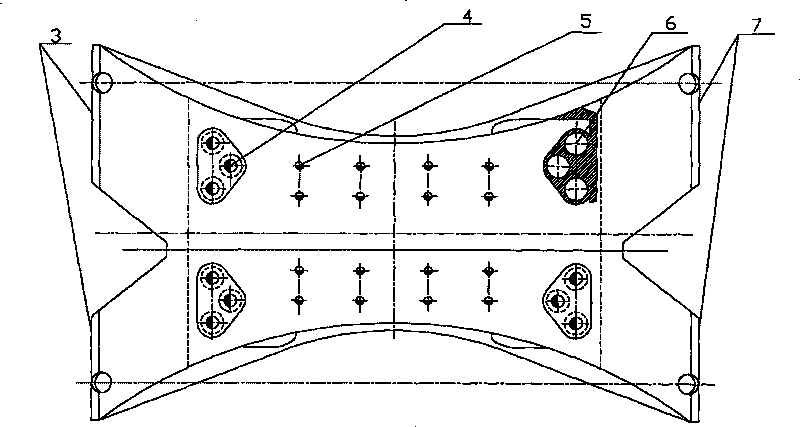

Spoke molding method and device

The invention discloses a spoke molding method and a spoke molding device. The spoke molding method comprises the following steps: arranging a cylindrical blank on a mold core of spinning equipment; clamping the peripheral wall part near the bottom end of the cylindrical blank with the mold core by using a lower clamping device; inwards spinning the peripheral wall near the top end of the cylindrical blank into a spoke top wall having a flat annular structure with a central hole by using a spinning device of the spinning equipment; removing the clamping of the lower clamping device on the cylindrical blank; clamping the annular flat top wall with the mold core by using an upper clamping device of the spinning equipment; spinning the peripheral wall part from the part below the top wall tothe bottom end of the cylindrical blank into a spoke peripheral wall which meets the requirement of shape and thickness by using the spinning equipment. In the molding method, the cylindrical blank is subjected to the spinning processing of the spoke top wall and peripheral wall on the spinning equipment in turn. Compared with the prior art, the method and the device save materials and greatly improve the production efficiency.

Owner:买联合 +1

Processing technique for casting beam of automobile chassis

InactiveCN101549458BGuaranteed accuracy requirementsPrecise positioningOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention relates to a processing technique for casting a beam of an automobile chassis, which comprises the following steps of: (1) milling a lower bottom surface, (2) milling an upper plane surface, (3) milling two lateral sides, (4) drilling a hole in the lower surface, (5) drilling a hole in the upper surface, (6) drilling holes at the two lateral sides, (7) boring holes at two lateral inclined surfaces, (8) milling an inner convex plate inclined surface at one side, (9) milling the inner convex plate inclined surface at the other side, (10) drilling screw holes on the inner convex plate inclined surface, (11) tapping inclined surface screw holes, (12) back facing of a hole table-board on the lower bottom surface, (13) back facing of a hole table-board on the upper plane surface and (14) back facing of hole table-boards on two lateral surfaces. The technique process has reasonable procedure arrangement, is convenient for the positioning and clamping of work pieces, and can guarantee the precision requirement of the work pieces and high processing efficiency.

Owner:SINO TRUK JINAN POWER

An automated method for bacterial community composition and diversity analysis of 16S rRNA genes

ActiveCN106815492BVarious methods of data mining analysisIn-depth analysis of data mining methodsSequence analysisInstrumentsData profilingAnalysis tools

The present invention discloses an automated method for bacterial community composition and diversity analysis of 16S rRNA genes. The 16S rRNA sequencing data analysis process provided by it uses sequencing raw sequence data as input, and calls industry-standard analysis tools (such as: Mothur , QIIME, etc.), and finally visualize the data and get easy-to-interpret analysis results. The present invention includes the current popular mainstream analysis items, and at the same time, the analysis content is modularized, the methods of data mining and analysis are more diverse and deeper, and different analysis module contents can be combined according to different needs, and the sequential flow arrangement is also more reasonable ; In addition, analysis errors caused by different sequencing depths are eliminated, making the analysis results more comprehensive, accurate and reliable.

Owner:SHANGHAI PASSION BIOTECHNOLOGY CO LTD

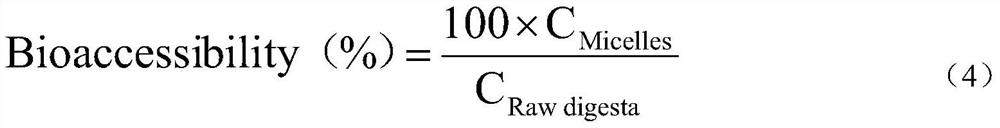

Beta-carotene emulsion with high bioaccessibility and preparation method thereof

PendingCN112493473AStrong solubilizing abilityPrevent precipitation from floatingFood ingredientsSucroseOil phase

The invention relates to a beta-carotene emulsion with high bioaccessibility. The beta-carotene emulsion with high bioaccessibility is prepared by subjecting oil-phase components and aqueous-phase components to homogenizing and emulsifying, the oil-phase components comprise carotene, camellia oil and olive oil, and the aqueous-phase components comprise sucrose ester, pectin and deionized water; wherein the mass percentage of the oil-phase components in the total components is 1-7%; the mass ratio of camellia oil to olive oil in the oil-phase components is 1: 1-1: 5; and the mass ratio of sucrose ester to pectin in the aqueous-phase components is 1: 0.5-1: 1. The beta-carotene emulsion with high bioaccessibility disclosed by the embodiment of the invention has the advantages of high bioaccessibility and good stability.

Owner:HAINAN UNIVERSITY

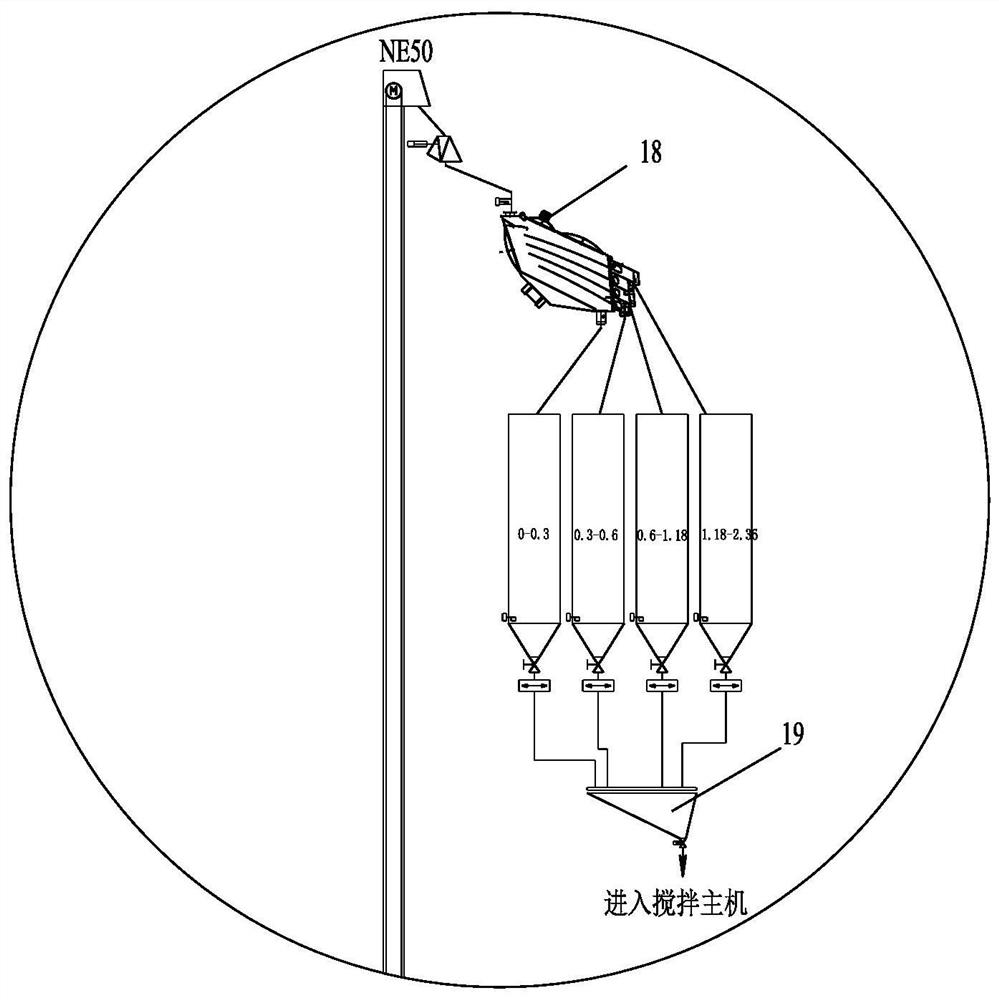

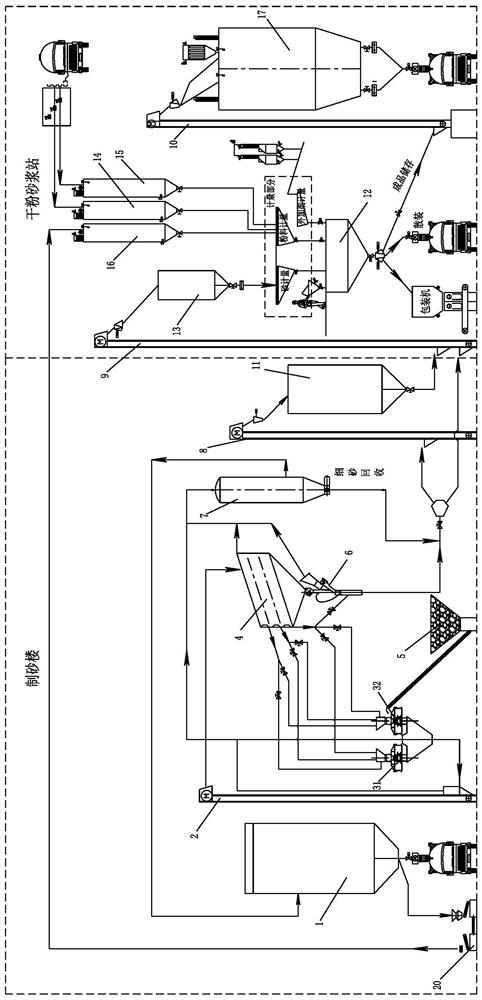

High-quality sand making and dry-mixed mortar integrated production line

The invention relates to a high-quality sand making and dry-mixed mortar integrated production line. The production line comprises a sand making building and a dry-mixed mortar station; a raw materialaggregate bin is connected with a graded sand making machine and a grain shape optimizing machine, raw material aggregate enters a vibrating screen through a semi-finished product bucket elevator after being crushed by the graded sand making machine and the grain shape optimizing machine, the aggregate enters a first sand finished product bucket elevator after the stone powder content of the aggregate is controlled by a winnowing device, and part of the aggregate returns to the graded sand making machine and the grain shape optimizing machine to be treated; fine sand in a stone powder separator returns to finished product machine-made sand, the treated stone powder enters a stone powder storage bin, and the stone powder storage bin sends the stone powder into a stone powder bin; fine sandtreated by the stone powder separator is fed into a dry sand storage bin through the first sand finished product bucket elevator, and then is fed into a dry sand temporary storage bin through a second sand finished product bucket elevator; and all the materials are stirred by a stirrer, enter a dry-mixed mortar finished product bin and are stored through a dry-mixed mortar finished product bucketelevator. The production line has the following advantages: the integrated design is adopted, the occupied area is small, and the process arrangement is compact and reasonable.

Owner:辽宁海诺重工股份有限公司

A method of making woodcarving color painting

ActiveCN105667173BReasonable process arrangementShort time consumingDecorative surface effectsLacquerPulp and paper industry

The invention relates to a manufacturing method for a wood carving colored drawing. The manufacturing method comprises the following steps of polishing, color fading, primer coating, polishing for a plurality of times and primer coating, tracing, coloring, gold drawing, and zapon lacquer coating. The manufacturing method of the colored drawing is reasonable in technique arrangement, short in consumed time and high in working efficiency. The wood carving colored drawing manufactured through the manufacturing method is uniform and harmonious in style, delicate and quite high in sense of depth and has the ancient charm and aesthetic sense to a greater extent.

Owner:泉州市红莲木雕艺术研究院有限公司

Pollution discharge pipe used for installation of open groove method

The invention relates to a pollution discharge pipe, in particular to the pollution discharge pipe used for installation of an open groove method. The pollution discharge pipe is composed of a water pipe body (1) with a circular cross section. The water pipe body (1) comprises a pipe outer diameter (1-1) and a pipe inner diameter (1-2). The pipe outer diameter (1-1) is composed of a small outer diameter face (1-1-1), an inclined plane (1-1-2) and a large outer diameter face (1-1-3). One end of the small outer diameter face (1-1-1) is connected with the large outer diameter face (1-1-3) through the inclined plane (1-1-2). An inclined angle of 5 degrees is formed between the inclined plane (1-1-2) and a horizontal plane. An annular boss (1-1-1-1) is arranged at the other end of the small outer diameter face (1-1-1). An annular groove (1-2-1) is formed at one end of the pipe inner diameter (1-2). The pollution discharge pipe used for the installation of the open groove method has the advantages of being in a flange-type structure, preventing a leakage phenomenon from occurring, and being reliable in sealing, good in tightness, good in reliability, simple in structure and low in manufacture cost.

Owner:溧阳市保珠建材厂

Processing technology for left and right bearings of a new suspension V-shaped thrust rod of a heavy-duty vehicle

ActiveCN103522010BGuaranteed accuracy requirementsPrecise positioningPivoted suspension armsEngineeringHeavy duty

The invention provides a technical scheme of a processing technology of a left support and a right support of a novel suspension V-shaped propelling rod of a heavy automobile. According to the technical scheme, the processing technology comprises the first step of milling a lower side face, the second step of milling a bottom face, the third step of drilling 14 bolt connecting holes and drilling and reaming 2 technological positioning holes, the fourth step of milling a boss inclined face on one side, the fifth step of milling a boss inclined face on the other side, the sixth step of drilling a boss inclined face thread bottom hole in one side, the seventh step of drilling a side boss inclined face thread bottom hole in the other side, the eighth step of tapping a boss inclined face thread hole, and the ninth step of using a counter bit for reaming platform tops of all holes in the bottom face with the bottom face 1 and the side face 7 used for positioning and a positioning circular hole used for auxiliary positioning. According to the processing technology, processing can be carried out on different machine tools according to different procedures, investment is low, and synergy is fast. The requirement of a product is guaranteed mainly through a tool, the technology arrangement is reasonable, a workpiece is positioned and tightly clamped conveniently, the requirement for the precision of the workpiece can be ensured, and processing efficiency is high.

Owner:SINO TRUK JINAN POWER

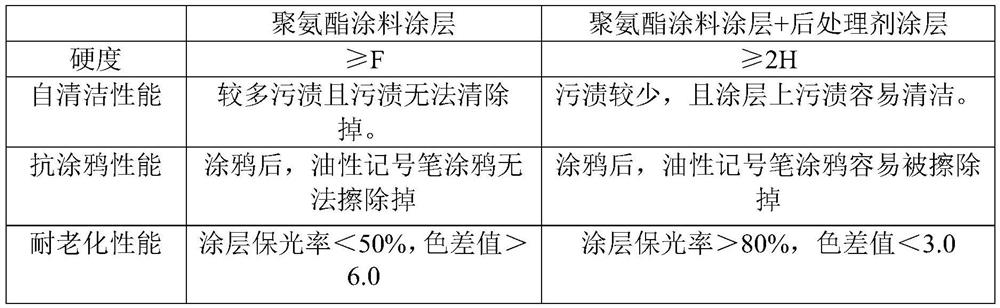

A post-treatment agent for antifouling self-cleaning paint and preparation method thereof

ActiveCN111334189BHigh hardnessImprove aging resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceCoating system

The invention relates to an antifouling self-cleaning paint post-treatment agent and a preparation method thereof. The anti-fouling self-cleaning paint post-treatment agent is used after the coating system is constructed and cured, and has fast drying, high hardness, anti-fouling self-cleaning performance and The advantages of excellent aging resistance can effectively improve the hardness, anti-fouling self-cleaning performance and aging resistance of the paint coating. The antifouling self-cleaning paint post-treatment agent includes the following raw materials in parts by weight: siloxane 5-10, silane coupling agent 0.5-2, polysiloxane oligomer 3-6, solvent 30-50 , thermoplastic resin 5-10, hydroxyl-containing silicone oil 1-3, polysilazane 10-20; the siloxane is selected from but not limited to methyltrimethoxysilane, methyltriethoxysilane, dimethyl One or more of dimethoxysilanes. The preparation method has reasonable process arrangement and simple operation, is suitable for large-scale industrial mass production, and no harmful substances and irritating odors are generated during the preparation process, and has good environmental friendliness.

Owner:广东四方威凯新材料有限公司

A Processing Technology of Transition Swing Arm of Steering Device of Heavy-duty Vehicle

ActiveCN103753113BGuaranteed accuracy requirementsPrecise positioningControl engineeringProcess engineering

The invention relates to the technical field of auto parts, in particular to a processing technology for a transition swing arm of a steering device system of a heavy-duty vehicle. Including: milling the upper end face of the large ball head; milling the lower end face of the large ball head: drilling process positioning hole: boring process positioning hole; milling the small end face of the large and small taper hole; Holes and taper holes: Inner hole and taper holes at the lower end of the large ball head: Drilling and reaming Large and small taper holes: Milling threaded holes Plane: Drilling and tapping threaded holes. Each procedure of the technological process of the present invention is all processed on common machine tools, with less investment and quick efficiency increase. Mainly rely on the tooling to ensure the product requirements, the process arrangement is reasonable, it is convenient for workpiece positioning and clamping, the accuracy requirements of the workpiece can be guaranteed, and the processing efficiency is high.

Owner:SINO TRUK JINAN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com