High-quality sand making and dry-mixed mortar integrated production line

A dry powder mortar and production line technology, which is applied in the dry powder mortar integrated production line and the field of high-quality sand making, can solve the problems of increasing the production cost of the production system, reducing production efficiency, and occupying a large area, so as to save probability screens, improve production efficiency, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

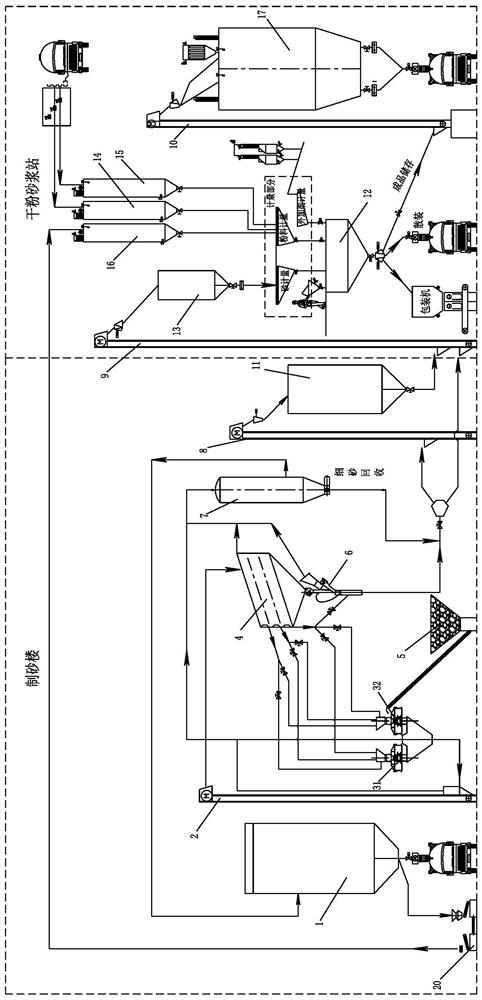

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0028] See figure 2 , an integrated production line for high-quality sand making and dry powder mortar, including a sand making building and a dry powder mortar station;

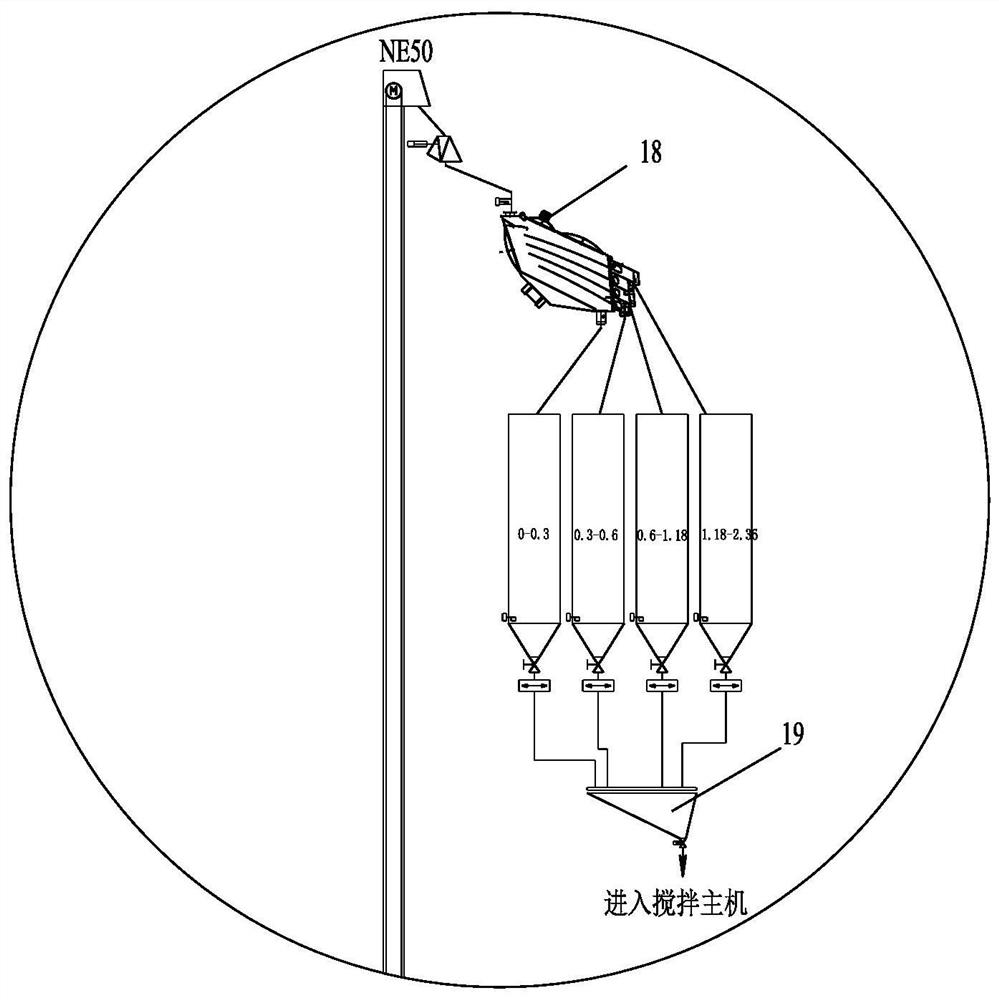

[0029] The sand making building includes stone powder storage bin 1, semi-finished bucket elevator 2, grading sand making machine 31, particle type optimization machine 32, vibrating screen 4, raw material aggregate bin 5, winnowing device 6, stone powder separator 7, and finished sand bucket Lifting machine 18, dry sand storage bin 11; the grading sand making machine 31 and the particle type optimization machine 32 are dual-machine sand, and the grading sand making machine 31 is mainly used for grading and adjustment of fineness modulus. The type optimization machine 32 is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com