Desulfurization chimney and manufacturing and mounting method thereof

An installation method and chimney technology, applied in separation methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of occupying a large cargo space, high LNG transformation costs, and difficult to predict the pressure of fuel costs in ship operation. Reasonable layout, high degree of design, high structural stability and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

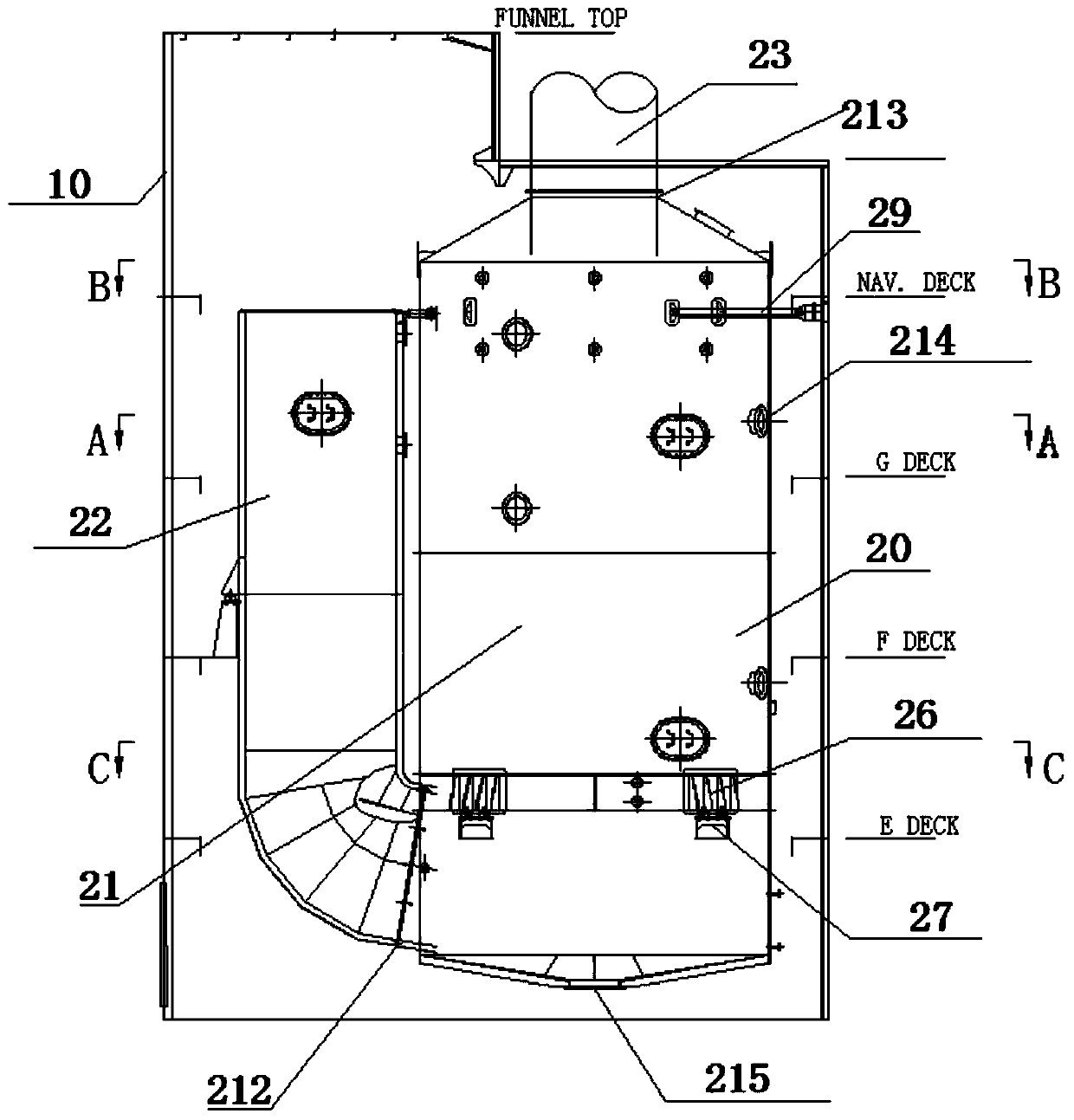

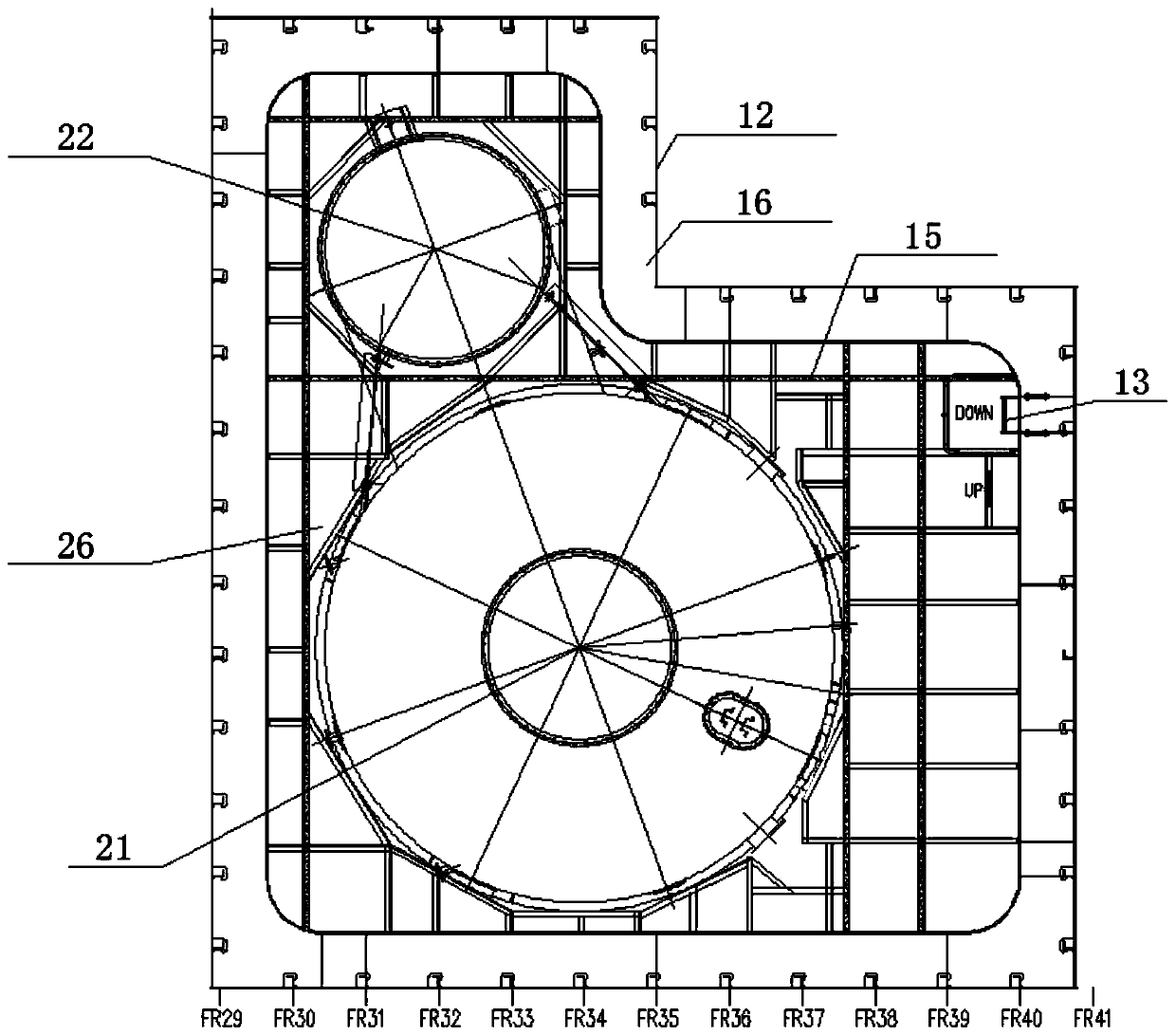

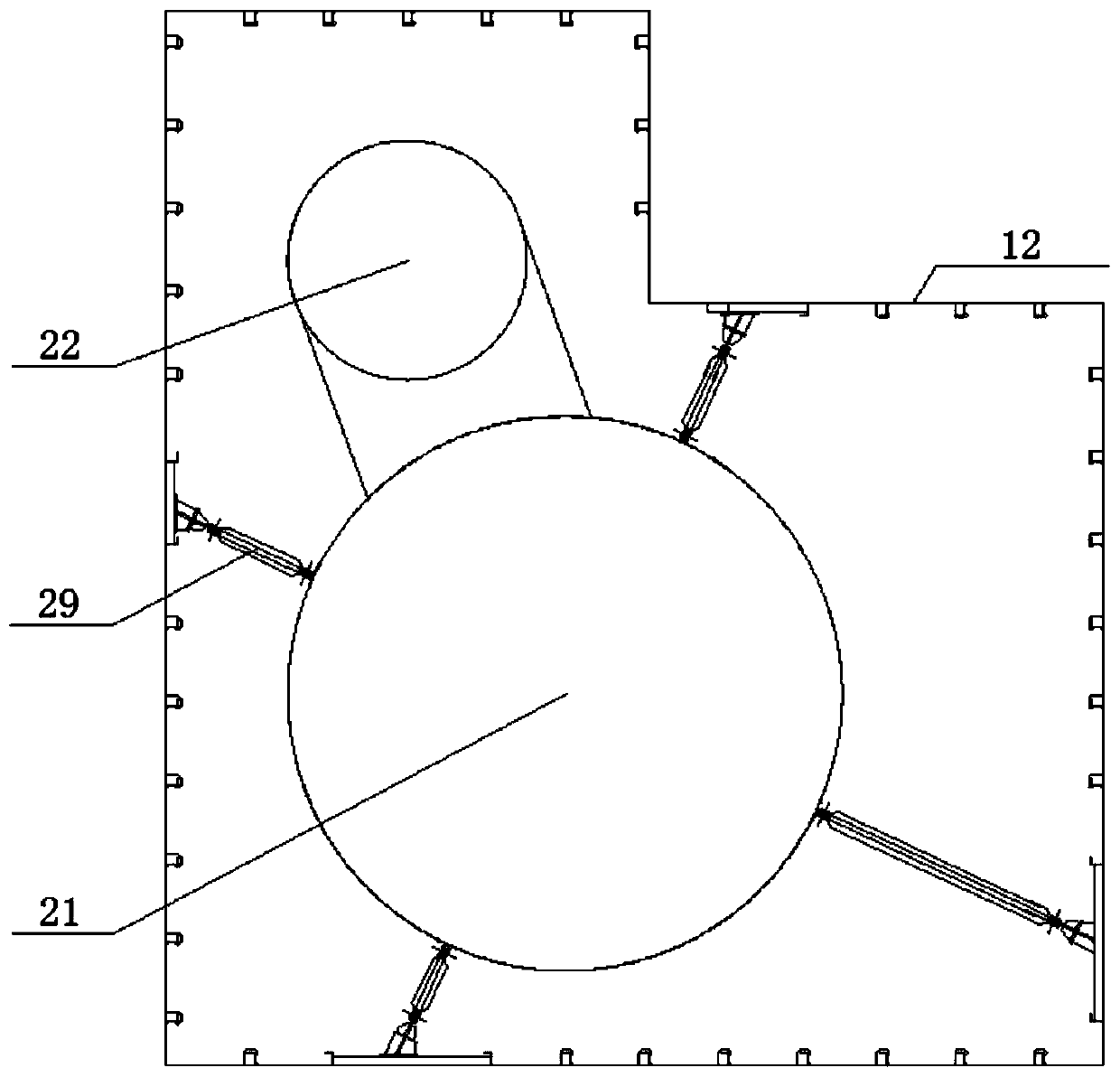

[0044] Please refer to Figure 1-4 , figure 1 It is a schematic structural diagram of the desulfurization chimney described in Example 1 of the present invention, figure 2 forfigure 1 The schematic diagram of the cross-section of A-A is shown, image 3 for figure 1 The schematic diagram of the B-B direction cross-section is shown, Figure 4 for figure 1 The schematic cross-section of C-C is shown. As shown in the figure, Embodiment 1 of the present invention provides a desulfurization chimney, which includes a chimney assembly 10 and a desulfurization device 20 disposed in the chimney assembly 10 .

[0045] The chimney assembly 10 includes an upper section of the chimney and a lower section of the chimney, and the upper section of the chimney and the lower section of the chimney all include some chimney surrounding walls; the chimney surrounding walls include side wall panels 12, frames (not shown in the figure shown) and some platform boards 16, the platform boards 16 ...

Embodiment 2

[0056] Embodiment 2 of the present invention provides a method for manufacturing and installing a desulfurization chimney, which includes the following steps:

[0057] 1) Prefabrication and splicing of the chimney assembly 10: the side wall panels 12, the frame 14 and several platform panels 16 are spliced and fixed to form the surrounding wall of the chimney, and are respectively spliced on the tire frame to form the upper section of the chimney and the lower section of the chimney ;

[0058] 2) Prefabrication and installation of the desulfurization tower base 27: the base panel 272 and the base web 274 are respectively spliced and fixed to form the desulfurization tower base 27, and the desulfurization tower base 27 is fixedly connected to the desulfurization tower base 26;

[0059] 3) Hoist the lower section of the chimney to the tire frame of the general group, position and fix it; lift the desulfurization tower 21 upright and hoist it into the lower section of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com