Pollution discharge pipe used for installation of open groove method

A technology for installation and sewage pipes, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of poor sealing, poor connection between the inner diameters of pipes, leakage, etc., and achieves good sealing and sealing. Reliable and reasonable process arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

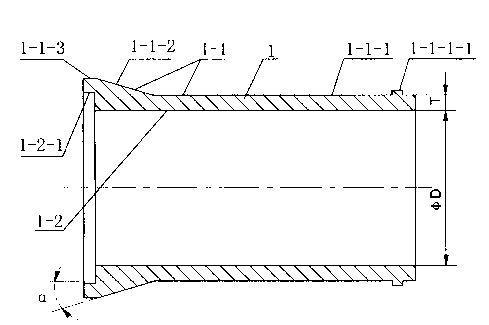

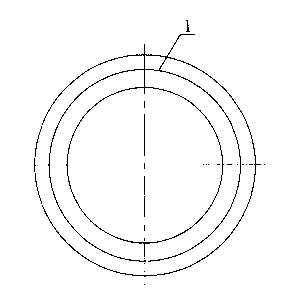

[0014] like figure 1 and figure 2 As shown, a sewage pipe for slotting installation is composed of a water pipe body 1 with a circular cross section. The water pipe body 1 includes a pipe outer diameter 1-1 and a pipe inner diameter 1-2. The pipe outer diameter 1-1 is composed of a small outer diameter surface 1-1-1, an inclined surface 1-1-2 and a large outer diameter surface 1-1-3, one end of the small outer diameter surface 1-1-1 and the large outer diameter surface The radial surface 1-1-3 is connected by the inclined surface 1-1-2, the angle α between the inclined surface 1-1-2 and the horizontal plane is 5°, and the other end of the small outer diameter surface 1-1-1 is provided with a ring Boss 1-1-1-1. One end of the tube inner diameter 1-2 is provided with an annular groove 1-2-1.

[0015] There is one ring-shaped boss 1-1-1-1.

[0016] The wall thickness of the water pipe body 1 is equal to 10% of the inner diameter 1-2 of the pipe. In the figure: T represents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com