A post-treatment agent for antifouling self-cleaning paint and preparation method thereof

A post-treatment agent and self-cleaning technology, applied in the field of coatings, can solve the problems of difficult environmental pollution, easy dust collection, high cost, etc., and achieve the effects of improving hardness and aging resistance, increasing cross-linking strength, and ensuring adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 of the present invention provides an antifouling self-cleaning coating post-treatment agent, which includes the following raw materials in parts by weight: siloxane 5, silane coupling agent 0.5, polysiloxane oligomer 3, solvent 30 , thermoplastic resin 5, hydroxyl silicone oil 1, polysilazane 10.

[0027] The siloxane is selected from but not limited to one or more of methyltrimethoxysilane, methyltriethoxysilane, and dimethyldimethoxysilane. In this embodiment, the silicon The oxanes include methyltrimethoxysilane and methyltriethoxysilane, the purity of which is not less than 99.0%, to prevent impurities from affecting the effect.

[0028] As an optional embodiment, the solvent is selected from but not limited to one or more of n-butyl acetate, n-butyl ether, xylene, in this embodiment, the solvent is n-butyl acetate, Its purity is not less than 99.5%, to avoid impurities affecting the effect.

[0029] The thermoplastic resin is a thermoplastic acrylic ...

Embodiment 2

[0031] Embodiment 2 of the present invention provides an antifouling self-cleaning paint post-treatment agent, which includes the following raw materials in parts by weight: siloxane 10, silane coupling agent 2, polysiloxane oligomer 6, solvent 50 , thermoplastic resin 10, hydroxyl silicone oil 3, polysilazane 20.

[0032] In this embodiment, the siloxane includes methyltrimethoxysilane, methyltriethoxysilane and dimethyldimethoxysilane, the purity of which is not less than 99.0%, to avoid impurities affecting the effect; The solvent is n-butyl ether and xylene, the purity of which is not less than 99.5%, so as to avoid the impact of impurities; the thermoplastic resin is cellulose acetate butyrate with a molecular weight of 20,000-50,000. The hydroxyl mass percentage of the hydroxyl-containing silicone oil is 2-5%.

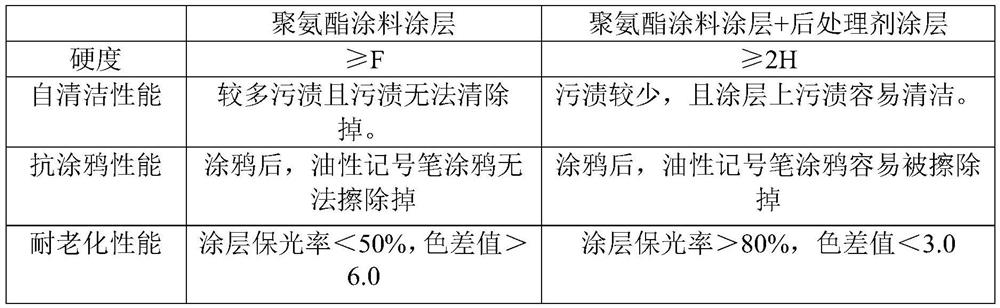

[0033] Compared with the prior art, the anti-fouling self-cleaning paint post-treatment agent described in the embodiments of the present invention is applied t...

Embodiment 3

[0039] Embodiment 3 of the present invention provides a kind of preparation method of antifouling self-cleaning coating post-treatment agent, it comprises the following specific steps:

[0040] 1) Weigh the raw materials according to the above-mentioned formula quantity, put the siloxane, silane coupling agent and polysiloxane oligomer into the reaction kettle, under the temperature condition of 110-120°C, Disperse evenly and react for 1 hour under the condition of rotating speed;

[0041] 2) Add the thermoplastic resin and hydroxyl-containing silicone oil to the mixture obtained in step 1) while dispersing, disperse evenly and fully react under heating conditions, add the solvent and lower the temperature of the obtained mixture to 5-15°C;

[0042] 3) Add polysilazane to the mixture obtained in step 2) and disperse for 30 minutes at a rotational speed of 800-1000 rpm;

[0043] 4) The mixture obtained in step 3) is filtered with a 5 μm filter bag filter and packaged to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com