Processing technique for casting beam of automobile chassis

A processing technology and automobile chassis technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., to achieve the effects of easy positioning and clamping, high processing efficiency, and guaranteed accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

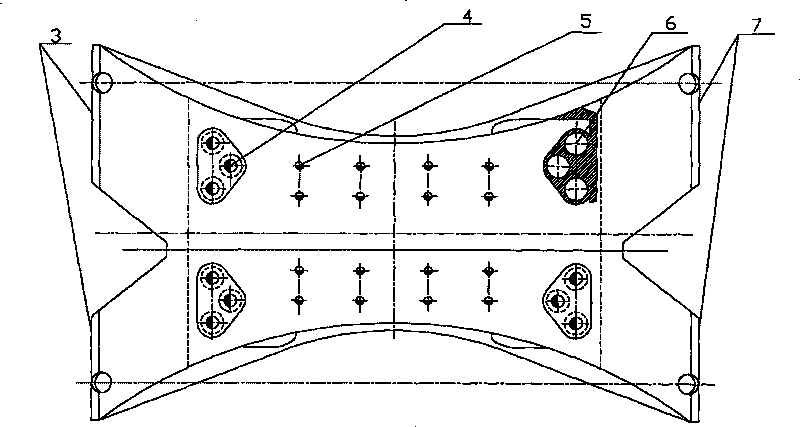

[0028] like Figure 1-5 A schematic diagram of the structure of the cast beam is given. Its processing process is:

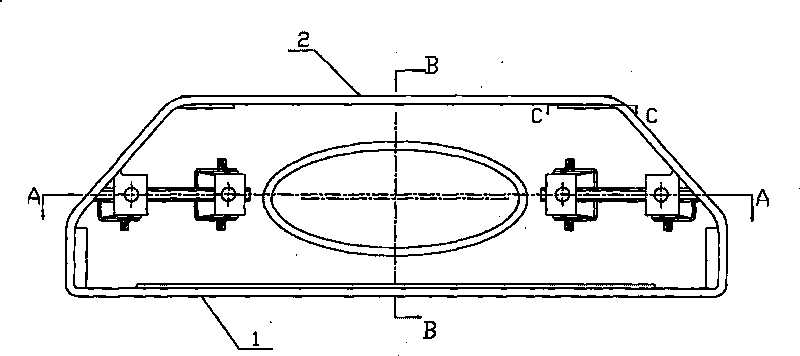

[0029] 1) The above plane 2 and the left side 3 are roughly positioned, clamped with a moving platen tool, and processed on an X2010A gantry milling machine, using a φ350 three-sided edge disc milling cutter to mill the bottom surface 1 (see figure 1 );

[0030] 2) Position the following bottom surface 1, clamp it with a movable platen tool, process it on an X2010A gantry milling machine, and use a φ32 three-sided disc milling cutter to mill the upper surface 2 (see figure 1 );

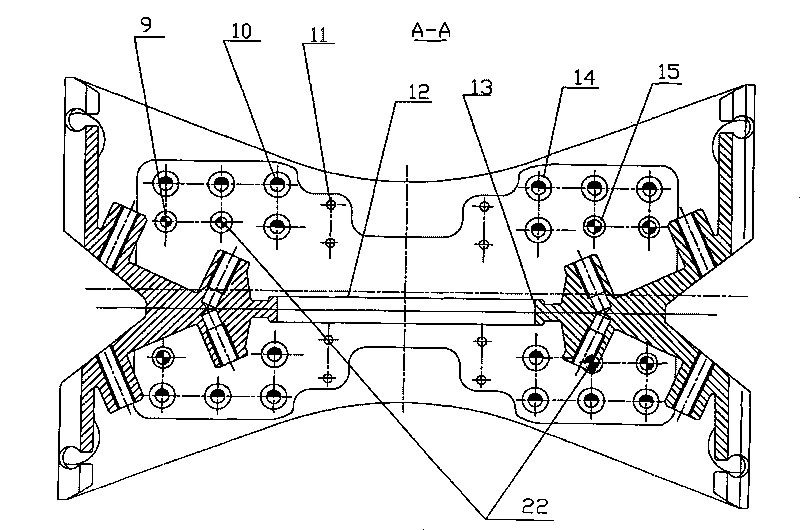

[0031] 3) The lower bottom surface 1 and the inner elliptical end surface 13 are used as the positioning, and the clamping tool is clamped with a moving platen type screw clamping tool. 2 Processed on -1258C face milling machine, using φ100 sleeve face milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com