Thin-wall elliptical part numerical control machining method

A processing method, ellipse technology, which is applied in the field of numerical control processing of thin-walled ellipse parts, can solve the problems of cumbersome processing technology, unstable clamping, and low processing accuracy, and achieve the effects of reasonable process arrangement, guaranteed processing quality, and solved bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

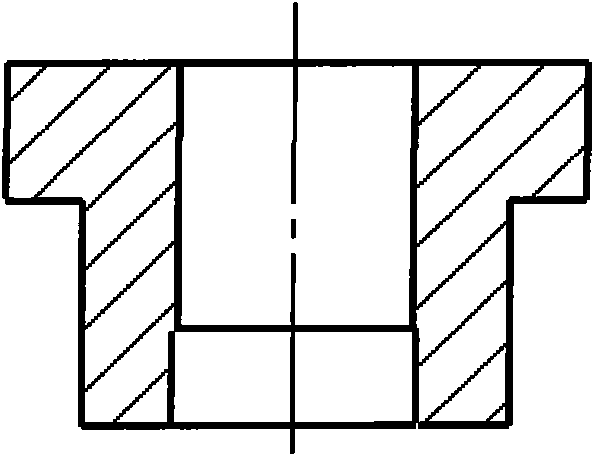

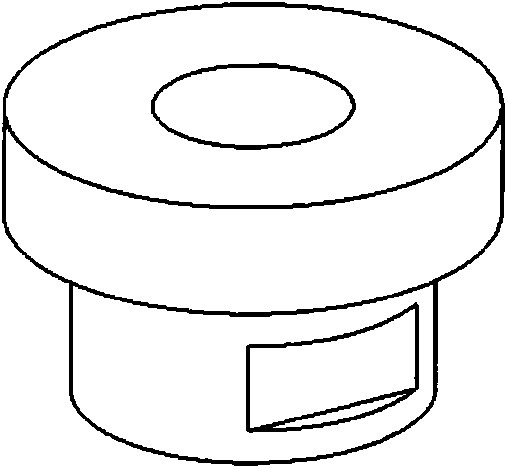

[0017] Such as Figure 1 to Figure 9 As shown, a numerical control processing method for thin-walled elliptical parts, including: the first step, blanking: prepare the aluminum bar on the sawing machine according to the drawing size; the second step, rough turning: rough turning on the CNC lathe according to the drawing size The end face, outer circle and inner hole of the bar; the third step, the milling process benchmark: a small plane is finely milled on the φ154mm cylindrical surface on the CNC milling machine as a process benchmark, which is convenient for the next step of drilling and alignment and milling inside the ellipse Alignment of the cavity and ring groove; the fourth step, drilling: alignment of process benchmarks, machining 8-φ6 holes on the CNC milling machine; fifth step, rough milling of elliptical inner cavity: alignment of process be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com