Process and electrolysis device for removing heavy metals in domestic garbage organic waste

A technology for organic waste and domestic waste, applied in photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of changing shape, secondary pollution, etc., achieve stable operation, save operating costs, and improve composting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

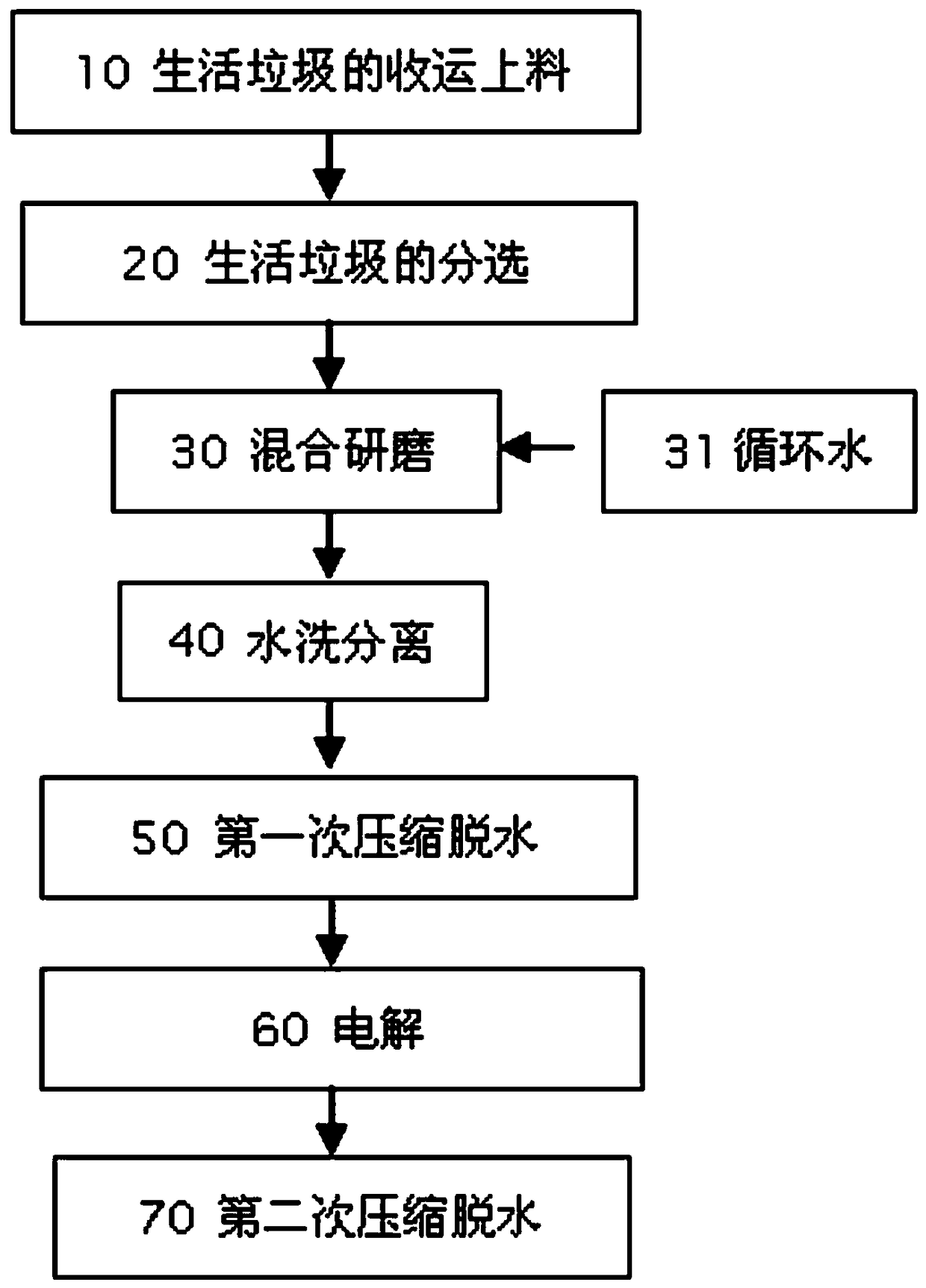

[0032] like figure 1 As shown, a process for removing heavy metals in domestic waste organic waste includes the following seven treatment processes:

[0033] 1) Household garbage collection and loading 10, transporting the household garbage from each garbage collection station to the production and processing point, and adding materials to the processing equipment for loading;

[0034] 2) Sorting 20 of household garbage, separating the garbage put into the sorting equipment. The sorting equipment mainly uses drum sieves and wind separators to effectively separate the 20mm-80mm particle size materials in the household garbage;

[0035] 3) mixing and grinding for 30 minutes, mixing the separated material with a particle size of 20 mm to 80 mm with water, and then grinding it through a grinder until it becomes a slurry;

[0036] 4) washing and separating 40, transporting the muddy mixture to the water separation tank, the mixture is divided into three parts, wherein the lighter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com