Processing technique for casting beam of automobile chassis

A processing technology, automobile chassis technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., to achieve the effect of less investment, reasonable process arrangement, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

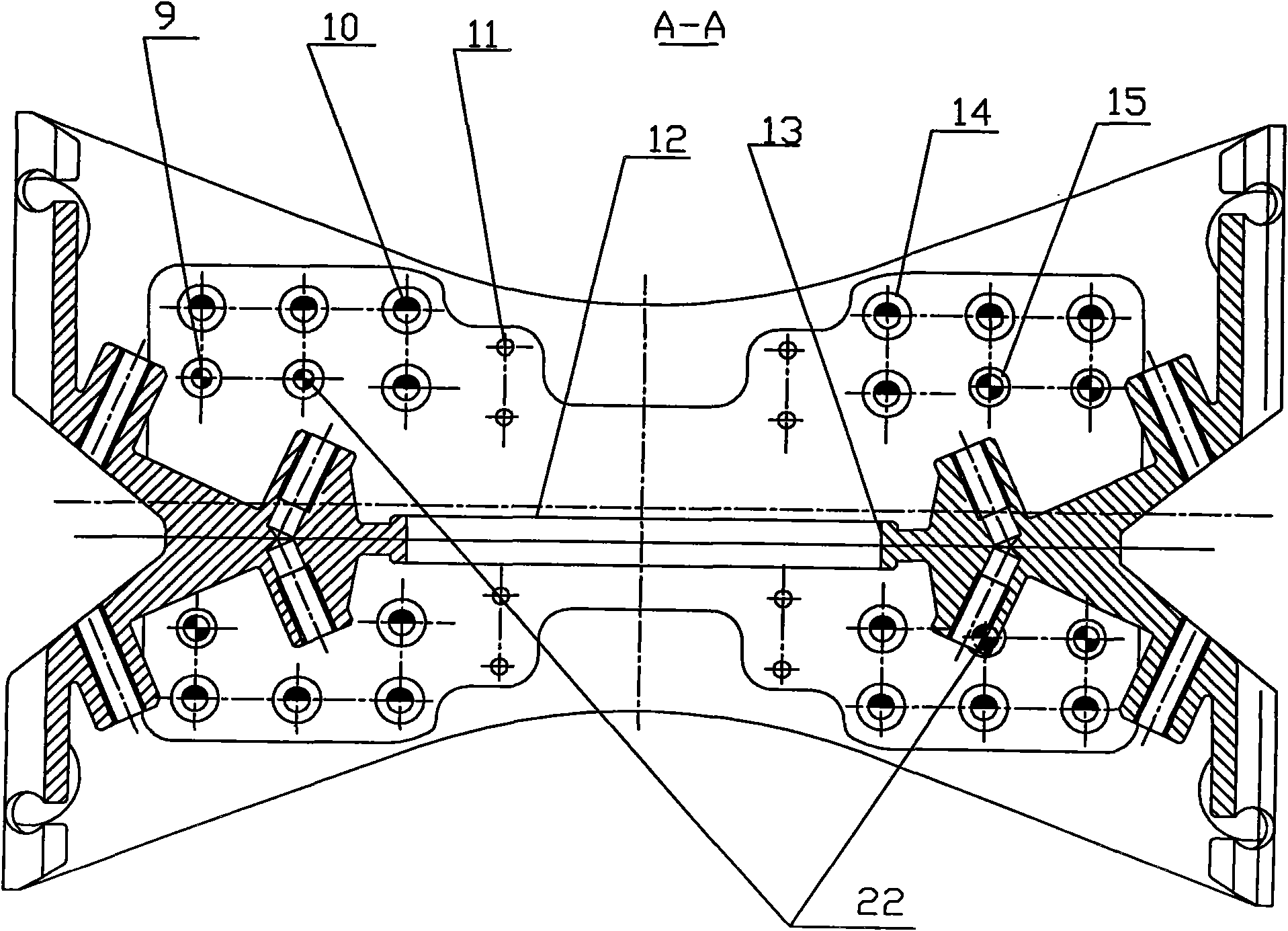

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

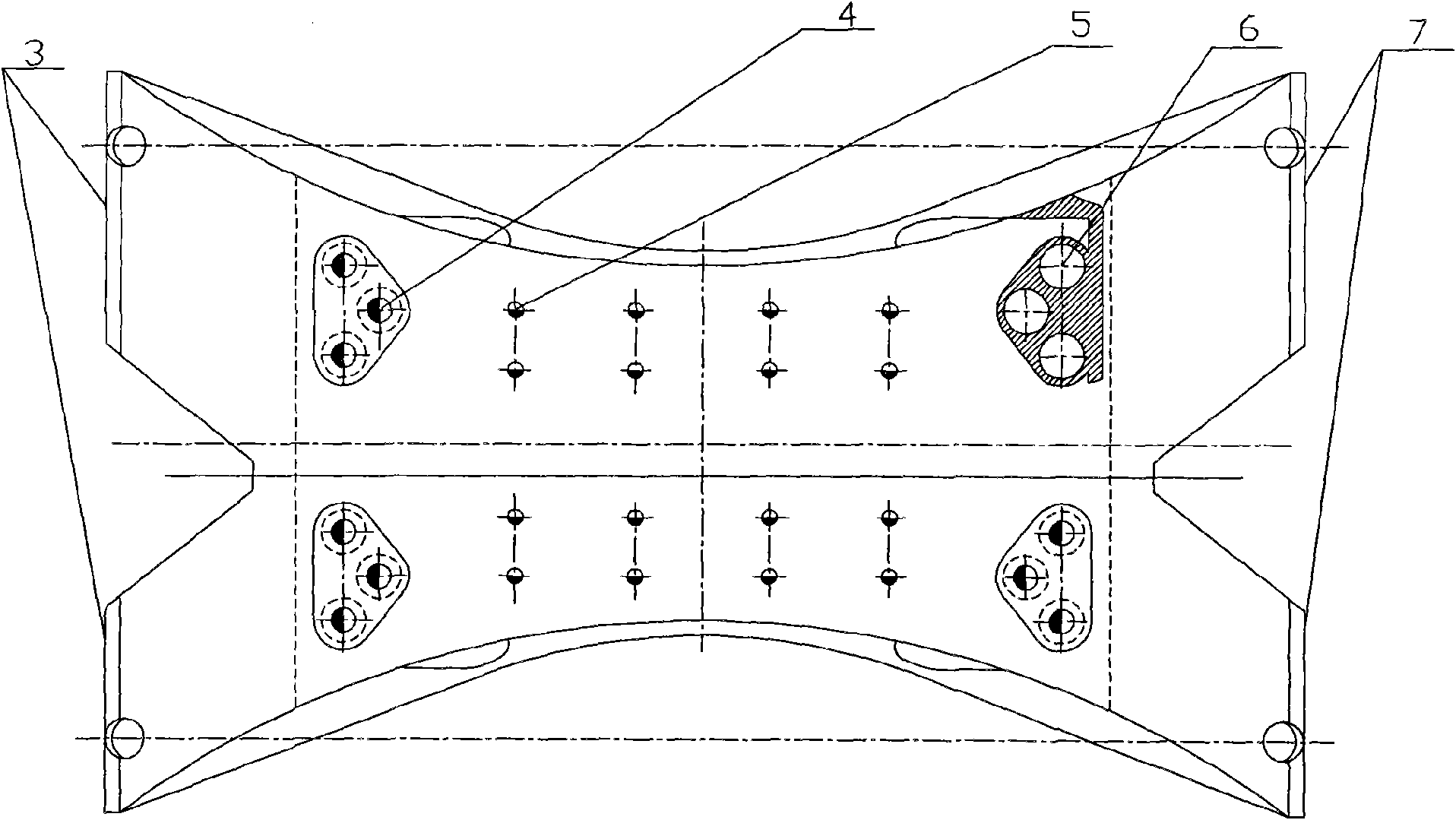

[0028] Such as Figure 1-5 The structure diagram of the cast beam is given. The processing process is:

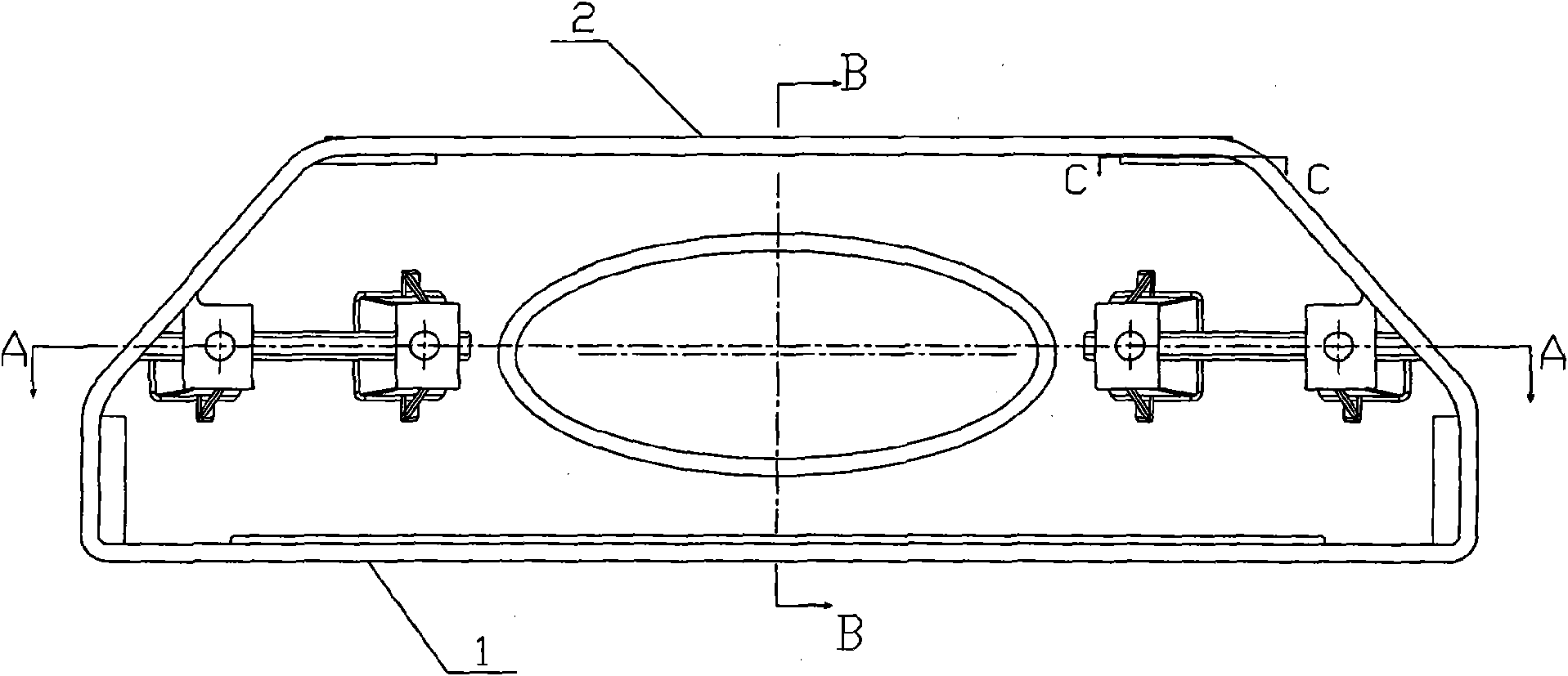

[0029] 1) The above plane 2 and the left side 3 are coarsely positioned, clamped by a movable platen tool, processed on the X2010A gantry milling machine, and milled with a φ350 three-sided disc milling cutter tool to mill the bottom surface 1 (see figure 1 );

[0030] 2) Position the bottom surface 1 below, clamp it with a movable platen tool, and process it on the X2010A gantry milling machine. Use a φ32 three-sided disc milling cutter to mill the upper plane 2 (see figure 1 );

[0031] 3) The following bottom surface 1 and inner elliptical end surface 13 are used for positioning, and clamped by a moving pressure plate type screw clamping tool. 2 -1258C end face milling machine processing, with φ100 set of face milling cutter tools, milling the left side 3 and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com