A Processing Technology of Transition Swing Arm of Steering Device of Heavy-duty Vehicle

A technology for steering devices and heavy-duty vehicles, applied in the field of auto parts, can solve problems such as unreasonable process arrangement, difficulty in meeting technical accuracy requirements for transition swing arms, and complicated operations, and achieves easy positioning and clamping, guaranteeing accuracy requirements, and process arrangements. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

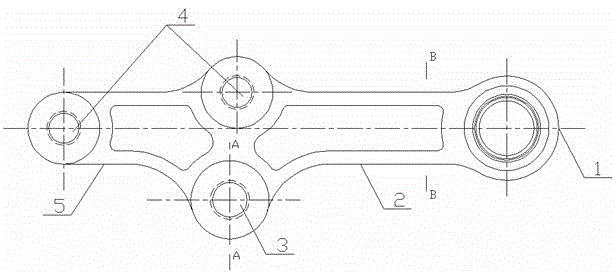

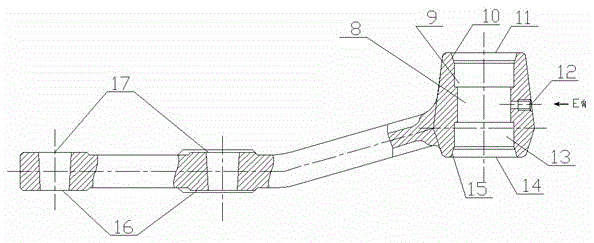

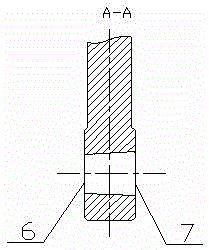

[0036] Such as Figure 1-5 A schematic diagram of the transition swing arm is given. Its processing process is:

[0037] (1) Mill the upper end surface 11 of the large ball head; use the lower end surface 14 of the large ball head and the outer diameter 1 of the large ball head as rough positioning, use the side surface 2 and the small end face 16 of the small tapered hole as auxiliary positioning, and use the moving platen tool to clamp, Machining on X5030 milling machine, using φ80 sleeve type face milling cutter, milling the upper end face 11 of the large ball head (see figure 1 and figure 2 );

[0038] (2) Milling the lower end surface 14 of the large ball head: the upper end surface 11 of the large ball head and the outer diameter 1 of the large ball head are used as positioning, and the side surface 2 and the large end surface 17 of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com