Surface printing machine and surface printing process

A printing process and printing machine technology, applied in the field of fabric processing, can solve the problems of poor printing effect, low production efficiency and high production cost, and achieve the effects of improving printing coloration and saturation, improving printing effect and reducing manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

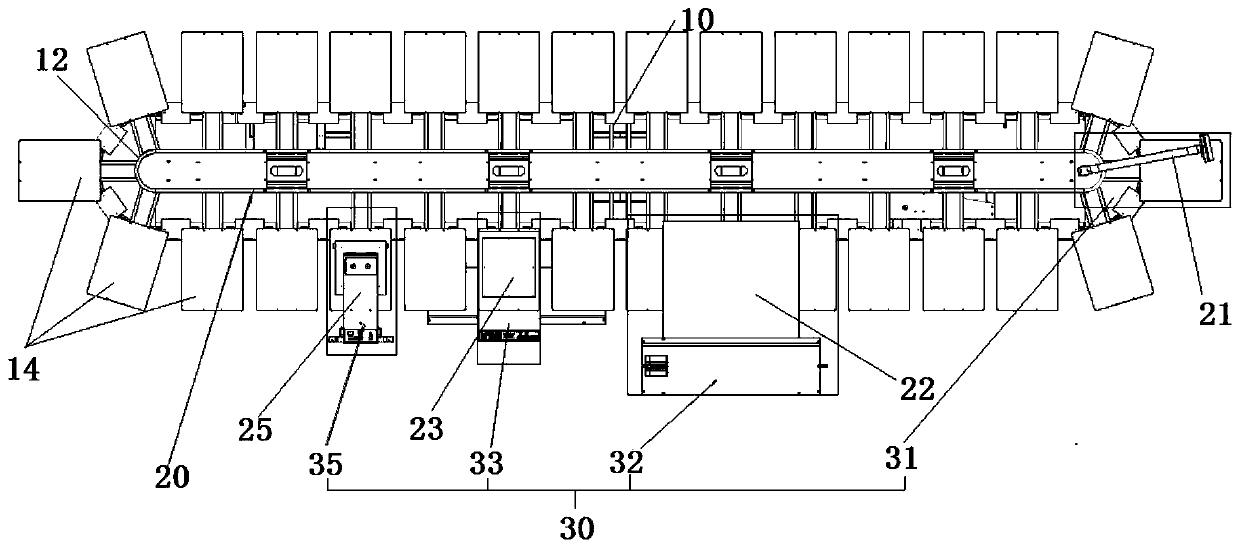

[0029] Please refer to figure 1 , figure 1 It is a schematic structural diagram of the surface printing machine described in Embodiment 1 of the present invention. The embodiment of the present invention provides a surface printing machine, which includes a frame 10, a printing mechanism 20, a driving mechanism (not shown) and a control mechanism (not shown); the frame 10 includes an annular guide rail 12 and several sliding arrangements The printing and dyeing station 14 on the circular guide rail 12; the circular guide rail 12 is provided with several functional areas 30, which successively include a scraping printing area 31, a spray printing area 32 and a drying area 33; the printing mechanism 20 includes a scraping printing device 21, The spraying device 22 and the oven 23 are installed in the scraping area 31, the spraying and printing area 32 and the drying area 33 of the circular guide rail 12 in sequence; , and sequentially pass through the scraping area 31, the spr...

Embodiment 2

[0034] An embodiment of the present invention provides a surface printing process, which uses the surface printing machine described in Embodiment 1 for surface printing, specifically including the following steps:

[0035] S1. Laser screen making: laser engraving the pattern to be printed on the scraping device;

[0036] S2. Pre-treatment: the printing and dyeing station moves to the pre-treatment area, the spreading device lays the fabric to be printed and dyed on the printing and dyeing station, and performs printing surface treatment on the fabric;

[0037] S3. Squeegee printing and heat treatment: after the printing surface treatment is completed, the printing and dyeing station moves to the scraping printing area, and the base color paste is scraped and printed on the fabric obtained in step S2 by using the scraping printing device, and then the printing and dyeing station moves to In the drying zone, heat treatment is carried out on the fabric scraped and printed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com