Method for regenerating aluminium-copper intermediate alloy by extruding waste copper-clad aluminium conductor and waste copper conductor for three times

A technology for copper-clad aluminum wire and intermediate alloy, which is applied in the field of three-time extrusion of waste copper-clad aluminum wire and waste copper wire to regenerate aluminum-copper intermediate alloy, can solve the problem that the recycled finished product cannot be used directly, is not suitable for large-scale application, and causes pollution in the recycling process. problems, to achieve the effect of saving energy consumption, convenient access, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

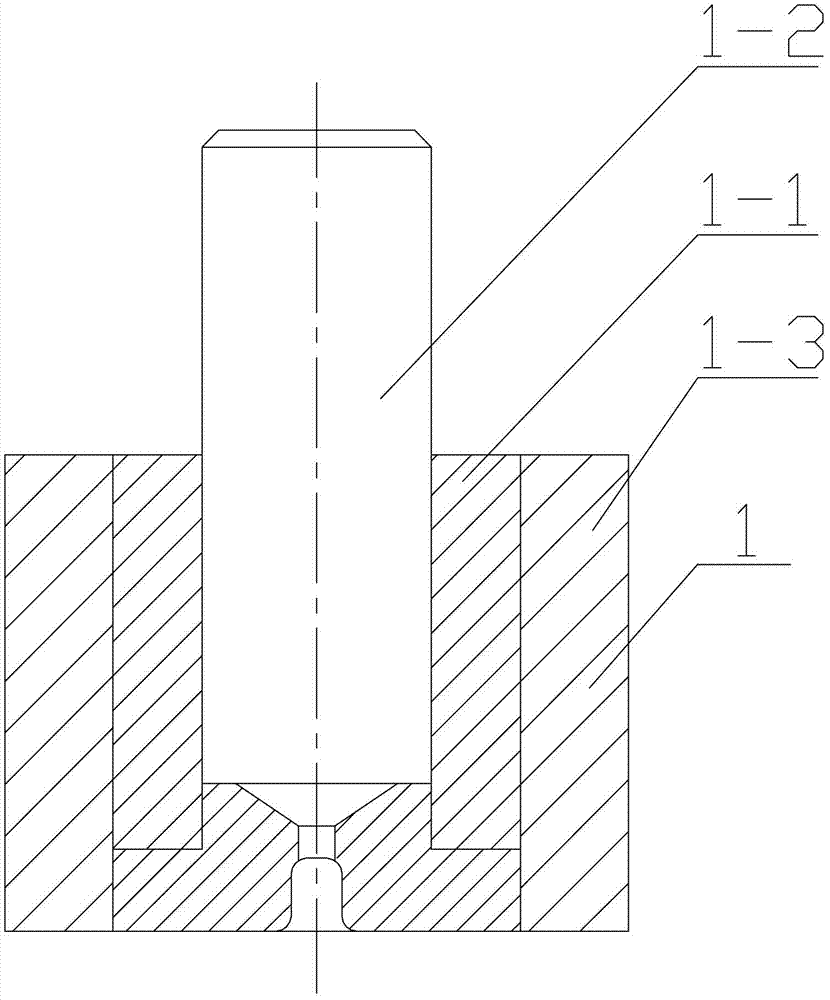

[0032] Specific implementation mode one: combine figure 1 Describe this embodiment, the specific steps of the method described in this embodiment are as follows:

[0033] Step 1. Machining waste copper-clad aluminum wires and waste copper wires:

[0034] Firstly, the recovered waste copper-clad aluminum wires and waste copper wires are bundled into bundles, and then the bundled waste copper-clad aluminum wires and waste copper wires are processed into waste copper-clad aluminum wires and waste copper-clad aluminum wires with a length of 0.5-1.0mm by using a pulverizer. Copper wire particles;

[0035] Step 2, assembly and feeding of extrusion die 1:

[0036] First assemble the extrusion die 1 and put the processed waste copper-clad aluminum wire and waste copper wire particles into the extrusion cylinder inner sleeve 1-1 of the extrusion die 1, and then insert the thermocouple into the extrusion cylinder inner sleeve 1-1 scrap copper clad aluminum wire and scrap copper wire ...

specific Embodiment approach 2

[0054] Specific implementation mode two: combination figure 1 To illustrate this implementation mode, the scrap copper wire described in step 1 in this implementation mode is a pure copper wire. Other method steps are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com