Combined stretcher

A stretching machine and stretching device technology, applied in the field of combined stretching machines, can solve the problems of copper-clad aluminum wire falling off, difficulty in manufacturing, and difficulty in tensioning copper-clad aluminum wire, so as to save costs and reduce workload , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

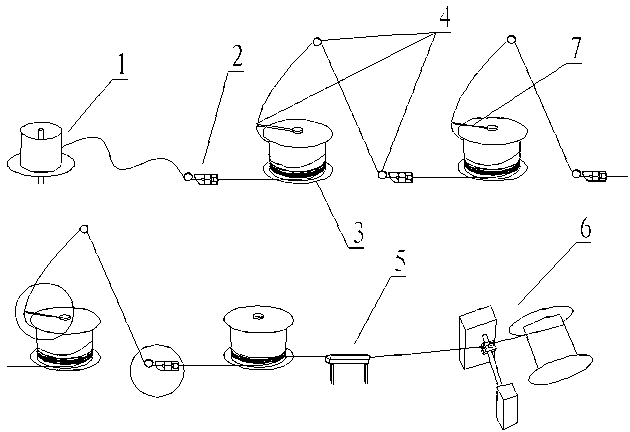

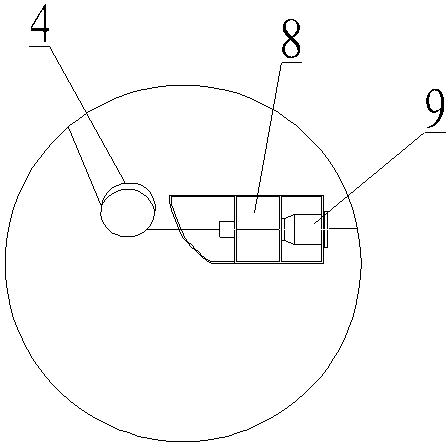

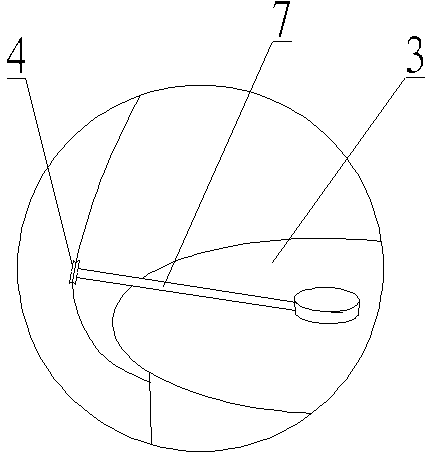

[0014] Such as figure 1 A combined stretching machine shown includes a wire take-up reel 1, a mold box 2, a wire winding reel 3, a guide pulley 4, a wire wiper frame 5, and a wire take-up reel 6, and the mold box 2 is provided with a lubricating liquid 8 and a pulley. Stretching die 9, the crossbar 7 that can rotate around the axis of the winding disk 3 is provided on the winding disk 3;

[0015] Its working principle is: the copper-clad aluminum wire is taken out from the take-up reel 1, and enters the mold box 2 through the guide pulley 4 in the right direction, and is stretched by the stretching die 9 under the lubrication of the lubricating liquid 8 in the mold box 2. Afterwards, the copper-clad aluminum wire is wound multiple times on the winding reel 3, and then introduced into the next mold box 2 through the guide pulley 4, and then in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com