Copper coated aluminum uni-core flame-retardant flexible electric cable and manufacturing method thereof

A manufacturing method and technology of flexible cables, which are applied in the manufacture of cables/conductors, insulated cables, cables, etc., can solve the problems of hard cables, low tensile force of aluminum materials, low strength, etc., and achieve low cost, less copper, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

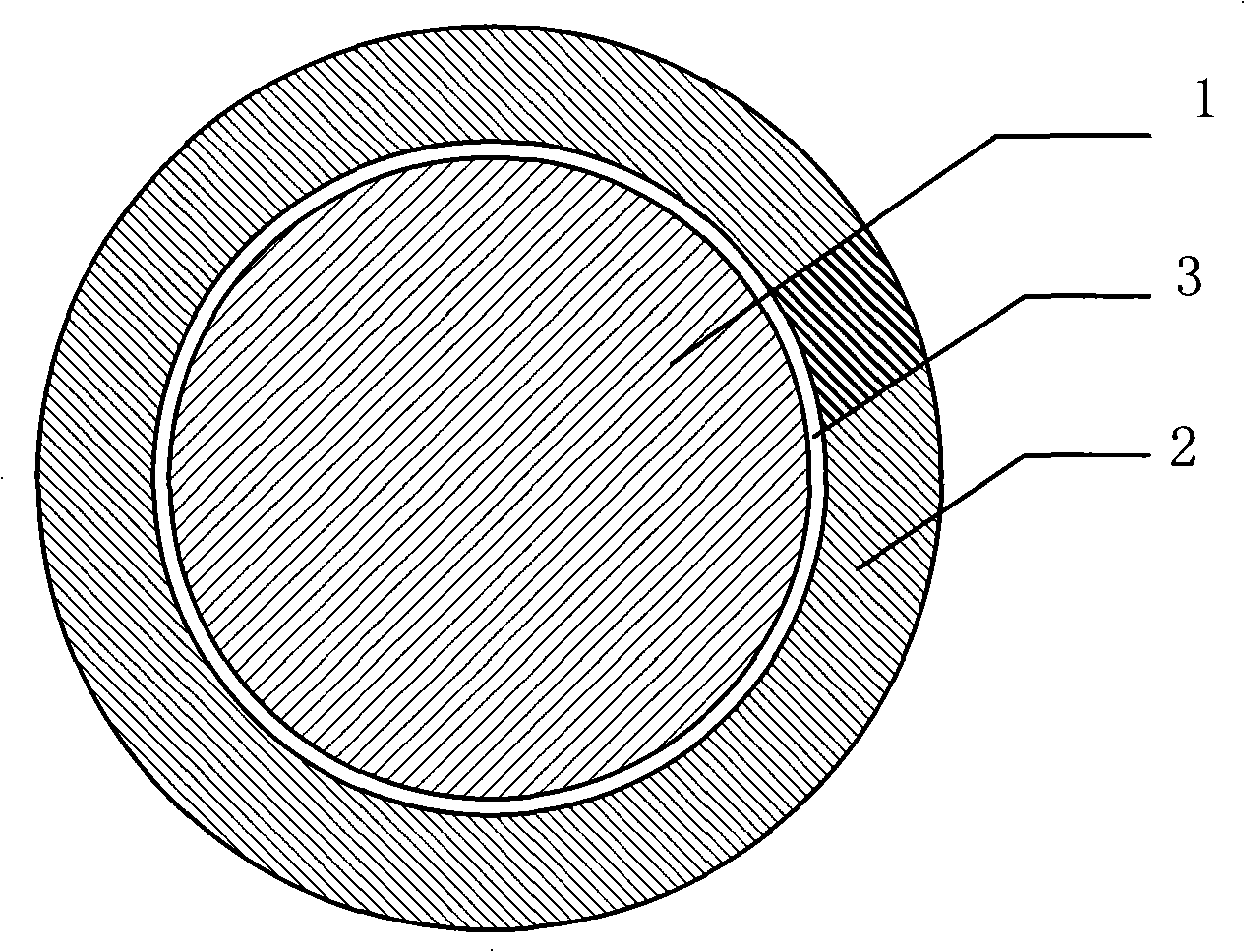

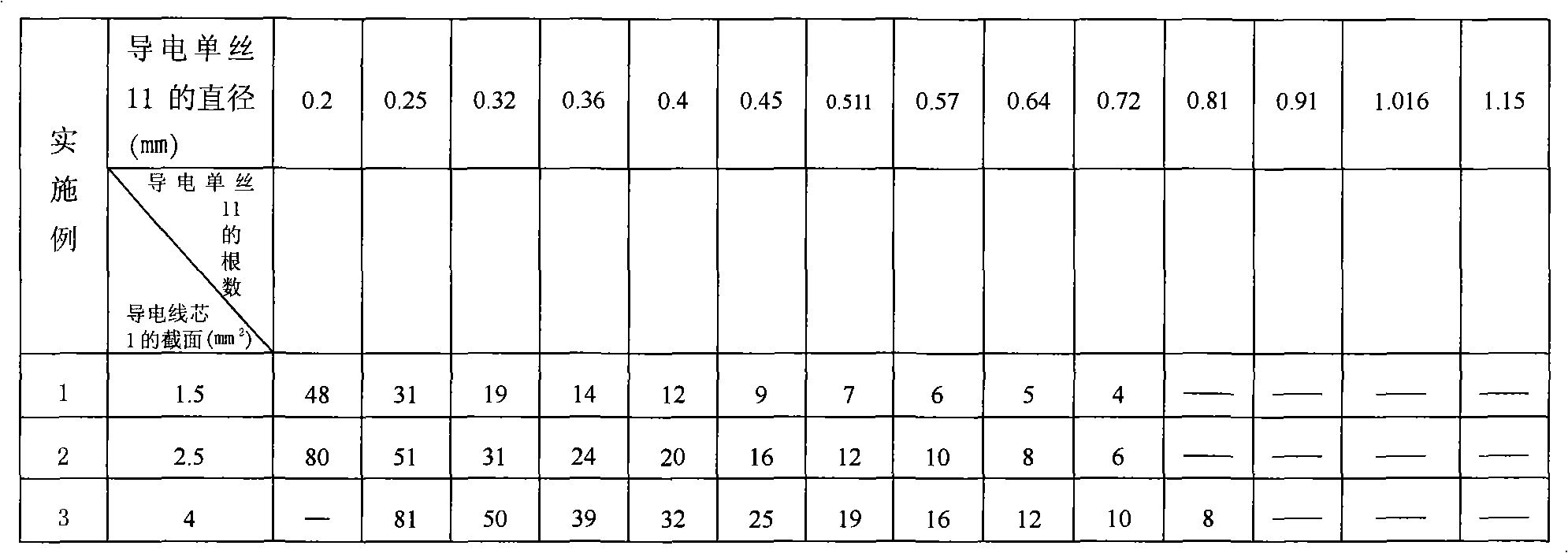

[0032] In one embodiment of the present invention, the manufacturing process of the copper-clad aluminum single-core flame-retardant flexible cable includes: the step of making the copper-clad aluminum wire into a single conductive core 1; An insulating treatment step of forming a flame-retardant insulating layer 2 on a conductive wire core 1.

[0033] In another embodiment of the present invention, the manufacturing process of the copper-clad aluminum single-core flame-retardant flexible cable of the present invention includes: the step of making the copper-clad aluminum wire into a single conductive core 1; The step of forming the isolation layer 3 ; and the insulating treatment step of extruding flame-retardant plastic on the isolation layer 3 to form the flame-retardant insulating layer 2 .

[0034] Wherein, the step of forming the isolation layer 3 may be: wrapping non-woven fabric on the outer surface of the single conductive core 1 .

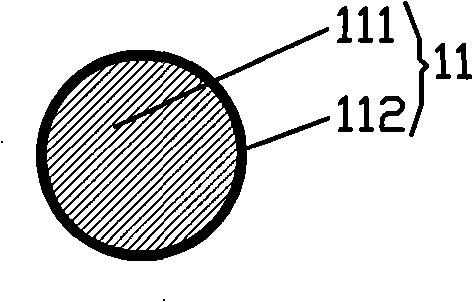

[0035] The step of making the cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com