Paying-off device for copper-clad aluminum wires

A copper-clad aluminum wire and pay-off device technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve problems such as low production efficiency, affect the quality of copper-clad aluminum wires, increase production costs, etc., and achieve the goal of ensuring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

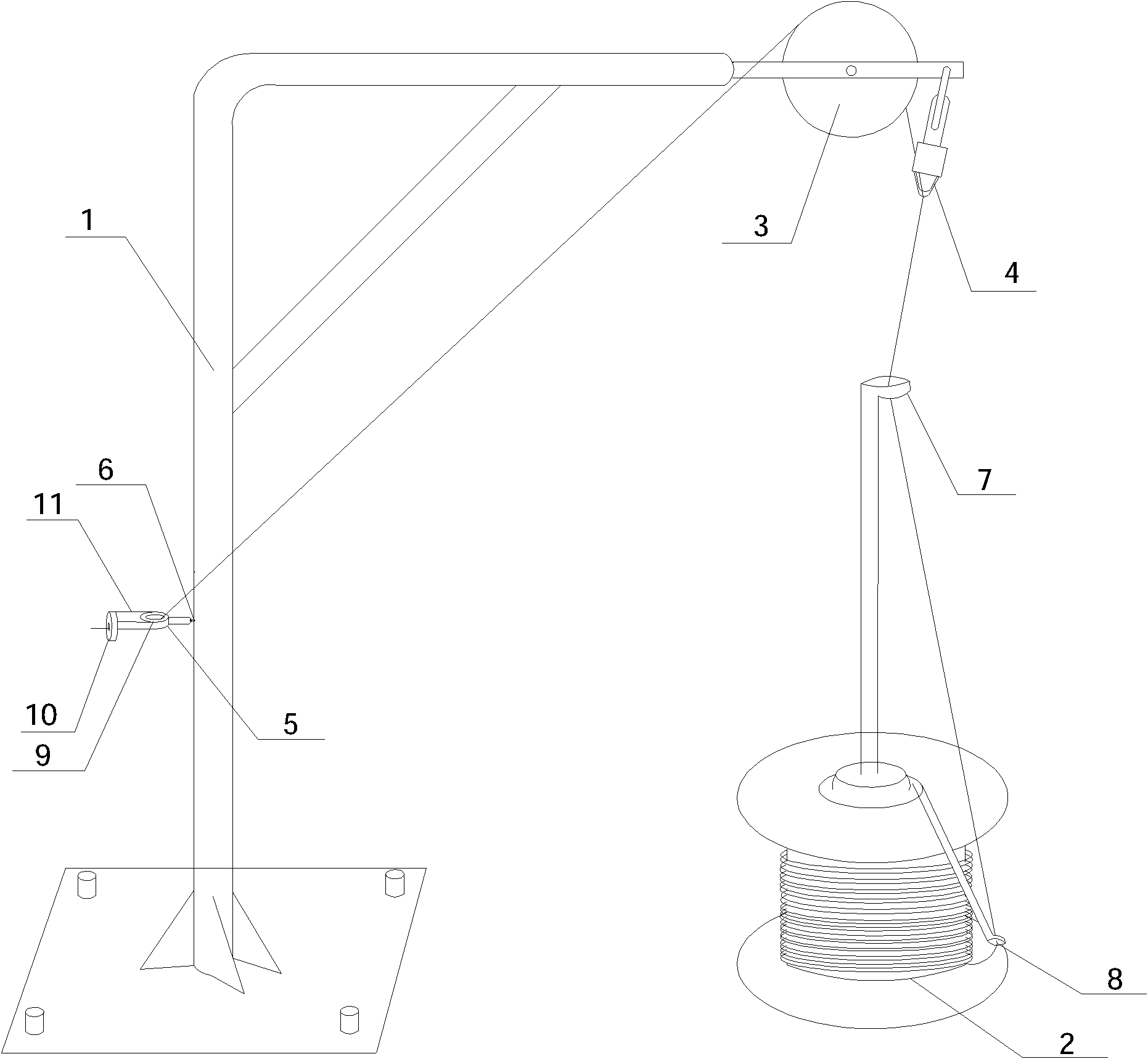

[0011] like figure 1 The shown copper-clad aluminum wire pay-off device includes a vertical support frame 1 and a pay-off reel 2, one end of the vertical support frame 1 is fixed on the ground, and the other end is provided with a guide wheel 3 and a wire wheel for the copper-clad aluminum wire to pass through. The vertically downward buffer hook 4, the vertical support frame 1 is provided with an outlet device 5 close to the ground, and the outlet device 5 is connected to the vertical support frame 1 by screws 6; there is a vertical buffer ring on the pay-off reel 2 7 and the rotatable lead rod 8 of obliquely downward. Wherein, the outlet device 5 is connected to the vertical support frame 1 by screws 6, so that the outlet device 5 can rotate.

[0012] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com