Clamp of shock absorption machine tool

A technology of machine tool fixtures and shock absorbing devices, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems of damaged items, poor shock absorption effect, etc., to reduce damage, prolong service life, and prevent wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

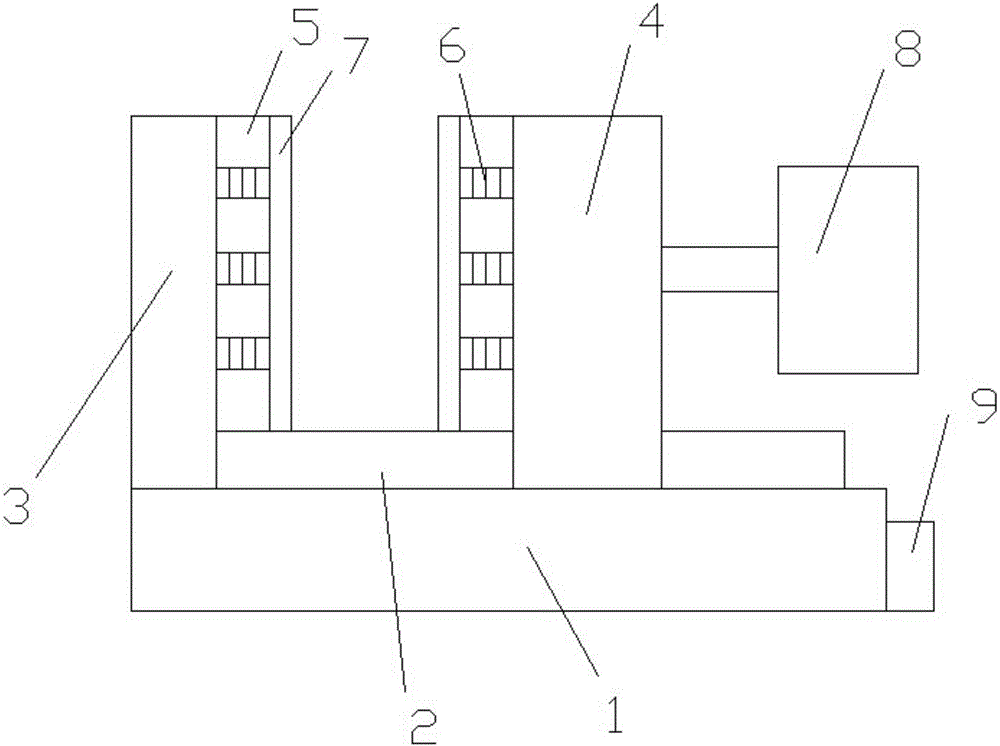

[0030] figure 1 The shock-absorbing machine tool fixture shown includes a base 1, on which a chute 2 and a controller 9 are arranged, one end of the chute 2 is fixedly connected to the first clamp body 3, and the other end of the chute 2 is slidably connected to the second clamp body 4, so The opposite sides of the first clip body 3 and the second clip body 4 are sequentially connected to the cushion layer 5 and the pressure sensor 7 from the inside to the outside. The cushion layer 5 is provided with a shock absorbing device 6, and the second clip body 4 The outside is connected to the cylinder 8, and the pressure sensor 7 and the cylinder 8 are both connected to the controller 9.

[0031] The first clip body 3 is fixedly connected to the base 1 by bolts.

[0032] The damping device 6 in the cushion layer 5 is a spring.

[0033] The number of springs in each cushion layer 5 is three.

[0034] The cushion layer 5 is made of rubber material.

[0035] Since the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com