Transformer copper-clad aluminum winding detector and detection method

A technology of transformer winding and copper-clad aluminum, applied in electrical winding testing, instruments, measuring electricity, etc., can solve the problems of large environmental impact, influence of imaging results, no non-destructive testing methods, etc., and achieves convenient operation and reasonable structure and composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

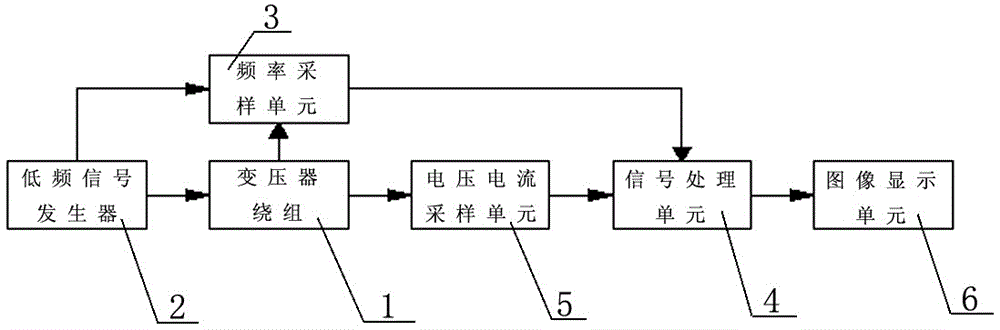

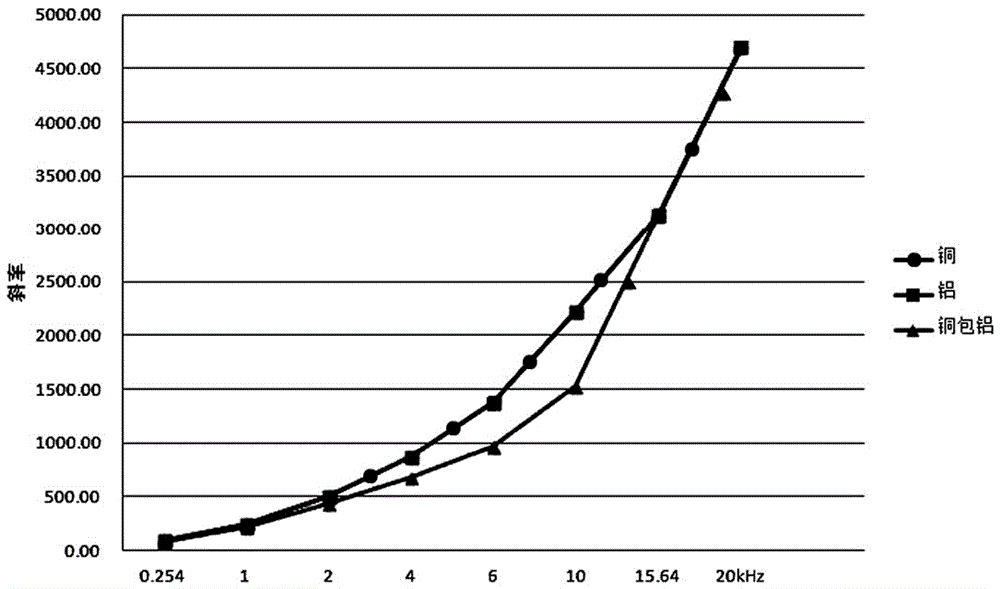

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a transformer copper-clad aluminum winding tester according to the present invention includes a low-frequency signal generator 2 connected to the transformer winding 1 and generating a sine wave signal with a frequency of 50Hz~35kHz to the transformer winding. The lead ends of the signal generator 2 and the transformer winding 1 are respectively connected to a signal processing unit 4 through the same frequency sampling unit 3, and the lead ends of the transformer winding 1 are also connected with a voltage and current sampling unit 5 capable of collecting sampling signals; The above-mentioned signal processing unit 4 performs signal integration and calculation, and then outputs the AC resistance slope at each frequency to the connected image display unit 6, and at the same time, the signal processing unit 4 calculates the output of the AC resistance slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com