High flame retarding radio frequency cable and manufacturing method

A radio frequency cable, high flame retardant technology, applied in circuits, electrical components, waveguides, etc., can solve the problems of physical foaming polyethylene insulation processing technology limitations, the degree of foaming cannot be too high, and there are many strip winding processes. The effect of shortening the processing cycle, small dielectric constant, and reducing the processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

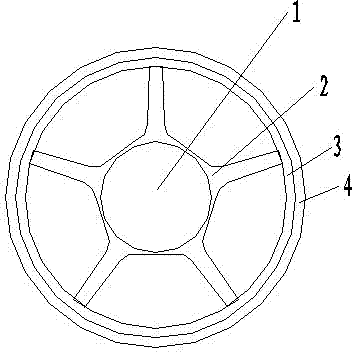

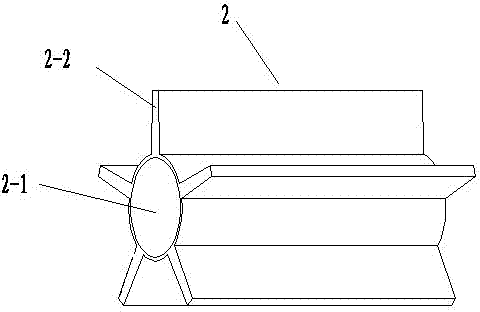

[0015] Such as figure 1 , 2 As shown, a high flame retardant radio frequency cable (SCAYKFK-50-12 type), including copper-clad aluminum wire inner conductor 1, corrugated copper tube outer conductor 3, also includes polygonal polyethylene skeleton semi-air insulation layer 2 (five-star Type insulating layer), PVDF sheath 4, the section center of the polygonal polyethylene skeleton semi-air insulating layer 2 is a tubular body 2-1, and several raised ribs 2-2 are arranged on the outer wall of the tubular body 2-1; The inner conductor 1 of the copper-clad aluminum wire is arranged in the tube core of the polygonal polyethylene skeleton type semi-air insulating layer 2 tubular body 2-1, and several raised ribs 2-1 of the polygonal polyethylene skeleton type semi-air insulating layer 2 2 is provided with a corrugated copper tube outer conductor 3, and a layer of PVDF sheath 4 is extruded outside the corrugated copper tube outer conductor 3.

[0016] A method for manufacturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com