Copper alloy and process for producing the same

A manufacturing method and technology of copper alloy, applied in the field of copper alloy and its manufacturing, can solve the problems of residue, difficulty, limitation of high strength and high electrical conductivity of alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Copper alloys having the chemical compositions shown in Tables 1 to 3 were vacuum-melted in a high-frequency melting furnace, and cast into molds made of zirconia to obtain cast pieces with a thickness of 12 mm. Rare earth elements Add individual elements or mixed rare earth elements.

[0113] Alloy

No.

Chemical composition (mass%, balance Cu and impurities)

The first group of elements

total

Elements of the second group

The third group of elements

total

Elements of the fourth group

total

be

Ti

Zr

Hf

Cr

1

2

3

4

5

15Fe, 1.0Si, 0.2Sn, 1.2Al

10Fe, 2.5Ni, 1.0Si, 0.4Zn

1.01Fe, 0.1Zn

0.99Fe, 0.5Ag

0.01Sn

17.4

13.9

1.11

1.49

0.01

0.05

0.49

1.02

1.51

1.93

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0.5Y, 0.01Nd, 0.02Ca

-

0.0...

Embodiment 2

[0157] In order to evaluate application to safety tools, samples were produced in the following manner, and abrasion resistance (Vickers hardness) and spark generation resistance were evaluated.

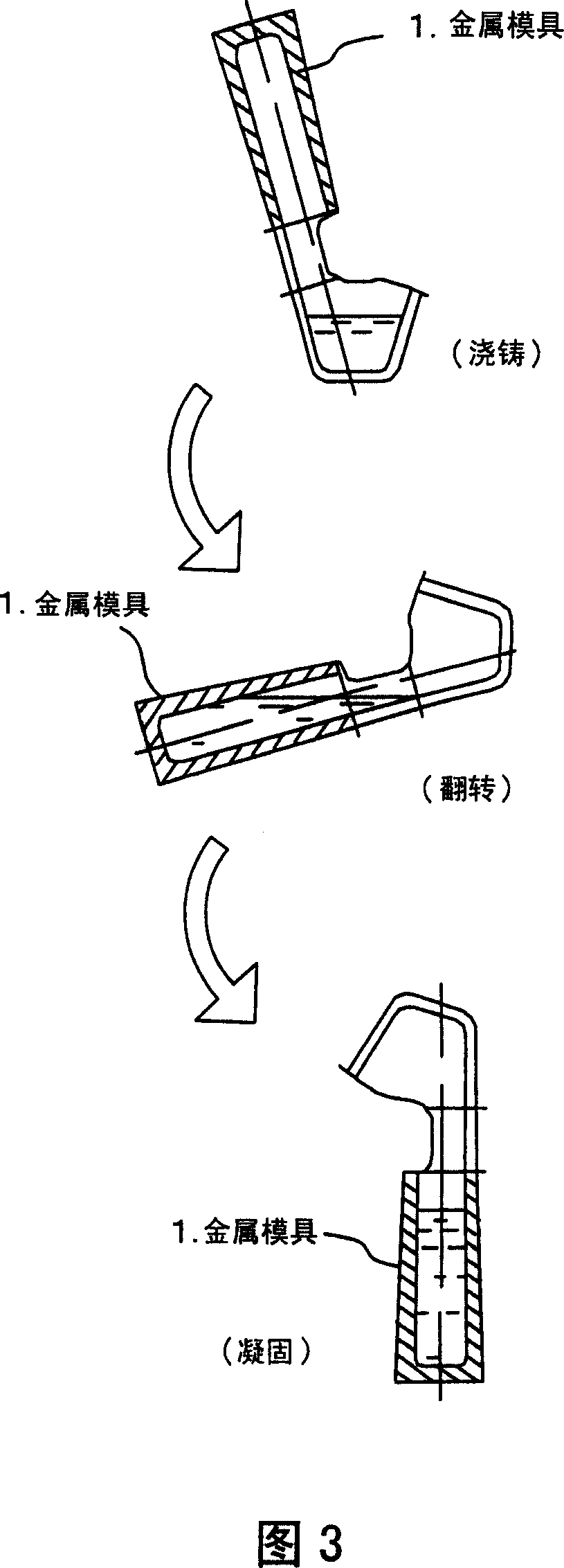

[0158] Alloys having the chemical compositions shown in Table 8 were melted in a high-frequency furnace in the atmosphere, and mold casting was carried out according to the Duvelly method. That is, in the state shown in FIG. 3(a), the metal mold 1 is kept, and while a reducing atmosphere is ensured with charcoal powder, after molten metal at about 1300° C. is injected into the metal mold 1, it is drawn as shown in FIG. 3( b ). ) is reversed, and solidified in the state shown in Figure 3 (c) to make a cast sheet. The metal mold 1 is made of cast iron with a thickness of 50 mm, and a hole for cooling is opened in the inside, and piping can be air-cooled. The cast piece is wedge-shaped to facilitate casting, the lower section is 30×300, the upper section is 50×400mm, and the height is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com