AlCoCrFeNiTix high-entropy alloy material and method for preparing same

A high-entropy alloy and alloy technology, applied in the field of AlCoCrFeNiTix high-entropy alloy and its preparation, to achieve the effects of high hardness, improved stability, and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

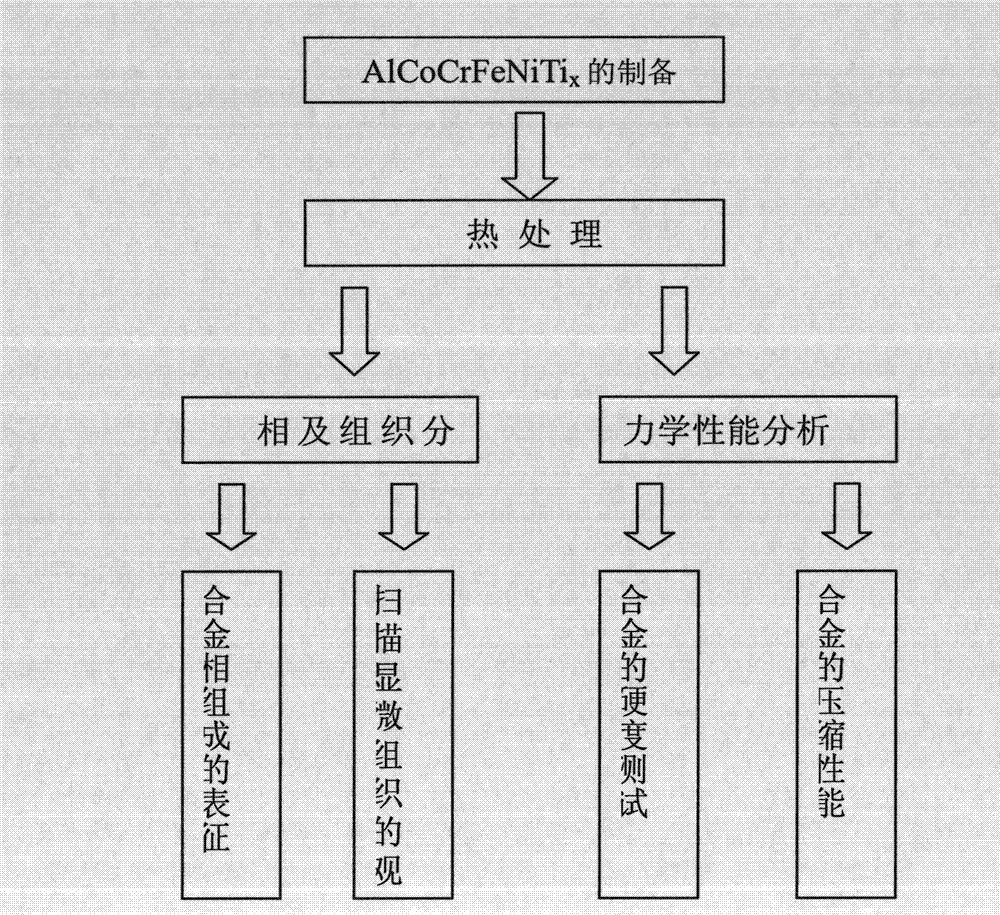

[0020] figure 1 A flowchart illustrating the steps of the present invention is illustrated.

[0021] 1. The preparation of multi-principal high-entropy alloys is a key step, and the preparation process has the following steps in sequence:

[0022] 1) Raw material preparation: the alloy smelting raw materials adopted in the present invention are high-purity (≥99.9%) Al, Co, Cr, Fe, Ni and Ti elements, which are accurately weighed and proportioned according to the molar ratio, and used for smelting and preparing alloys . The alloy composition is shown in Table 1.

[0023] Nominal composition (at%) of AlCoCrFeNiTix (x=0, 0.1, 0.2, 0.3, 0.4 and 0.5) high-entropy alloys (HEAs) with different Ti contents

[0024]

[0025] Table 1

[0026] 2) Purification of pure metals: the alloy preparation uses high-purity (99.9%) Al, Co, Cr, Fe, Ni, Ti as raw materials, and uses boric anhydride to purify high-purity metal surface oxides. Put into the test tube, then put the pure metal to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com