Temperature sensitive type water gel medicine release system and its preparing method

A temperature-sensitive, temperature-sensitive hydrogel technology, applied in the field of medicine, to prolong antigen presentation time, prevent burst release effect, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Preparation of a novel temperature-sensitive hydrogel with BSA supported by polysaccharide polymer particles-temperature-sensitive hydrogel composite method

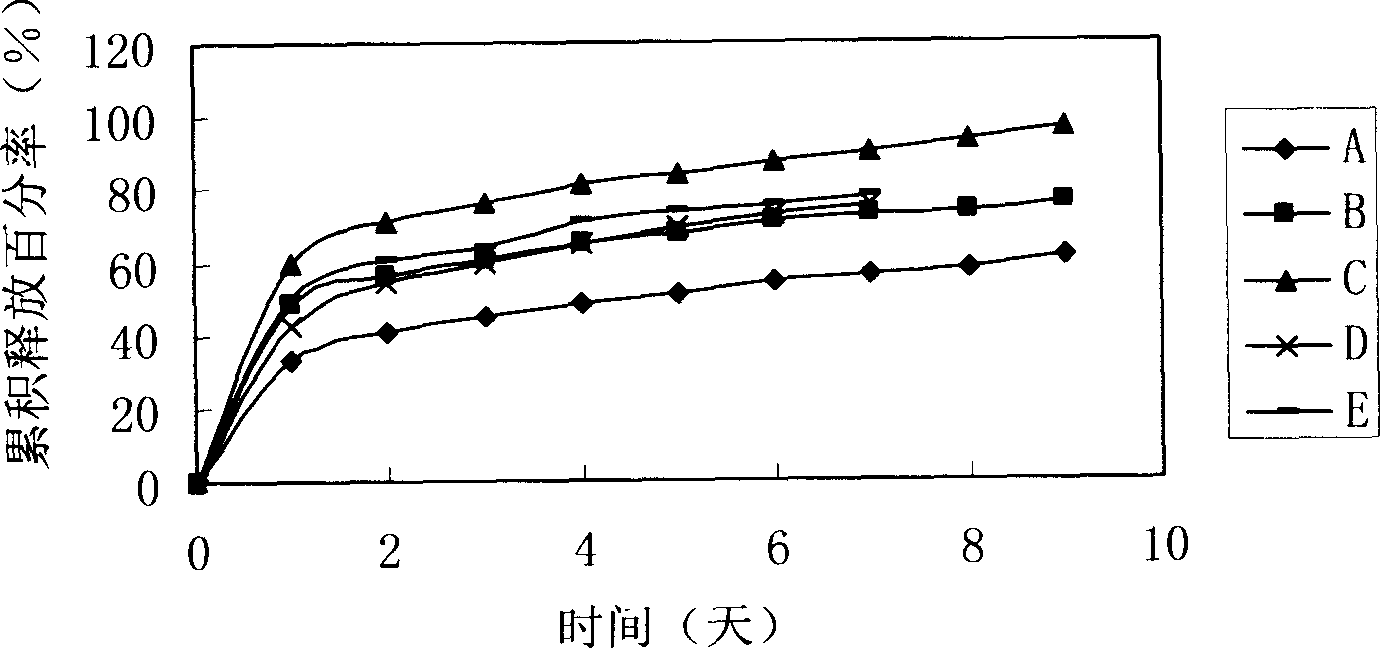

[0044] Choose BSA as a model drug, prepare a mixed solution of dextran, BSA and a mixed solution of polyethylene glycol and sodium alginate; mix and homogenize the two to obtain a stable emulsion; freeze for 12 hours, vacuum dry for 24 hours, and use the solid sample Wash with dichloromethane, centrifuge, pour to remove the supernatant and wash off polyethylene glycol at night, and evaporate the organic solvent to obtain polysaccharide polymer particles of dextran-sodium alginate. Before use, the temperature-sensitive hydrogel matrix is prepared into a 25% solution, and the polymer polysaccharide particles are added to the compound. In the composition, BSA (0.1%, w / w), dextran (5%, w / w), temperature-sensitive hydrogel matrix (90%, w / w), sodium alginate (4.9%, w / w) . The composition is released in vitro in HEPEs buff...

Embodiment 2

[0046] Polysaccharide-temperature sensitive hydrogel emulsification method to prepare new temperature sensitive hydrogel with BSA

[0047] A mixed solution of dextran, BSA, sodium alginate, and trehalose is prepared, and the temperature-sensitive hydrogel matrix is made into a 25% solution. After mixing the two phases, homogenize to obtain a stable emulsion; freeze for 12 hours, vacuum dry for 24 hours, and the obtained solid sample can be reconstituted before use. In the composition, BSA (30%, w / w), temperature-sensitive hydrogel (29.55%, w / w), dextran (27.5%, w / w), sodium alginate (2.95%, w / w), Trehalose (10%, w / w). The composition is released in vitro in HEPEs buffer at 37°C for 10 days without sudden release and incomplete release, achieving an ideal and stable sustained release effect.

Embodiment 3

[0049] Preparation of a novel temperature-sensitive hydrogel with BSA supported by polysaccharide-temperature-sensitive hydrogel composite method

[0050] A mixed solution of dextran, BSA, and trehalose is prepared, and the temperature-sensitive hydrogel matrix is made into a 25% solution. After mixing the two phases, homogenize to obtain a suspension, ready to use. In the composition, BSA (25%, w / w), temperature-sensitive hydrogel (20%, w / w), dextran (50%, w / w), trehalose (5%, w / w) (poly Electrolyte). The composition is released in vitro in HEPEs buffer at 37°C for 10 days without sudden release and incomplete release, achieving an ideal and stable sustained release effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com