Cobalt-base catalyst adopting silicon oxide mesoporous foam as carrier, and application thereof

A technology of cobalt-based catalysts and silicon oxides, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low CH4 selectivity, high specific surface area, and reaction High activity and other problems, to achieve the effect of high specific surface area, good dispersion, and uniform active metal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

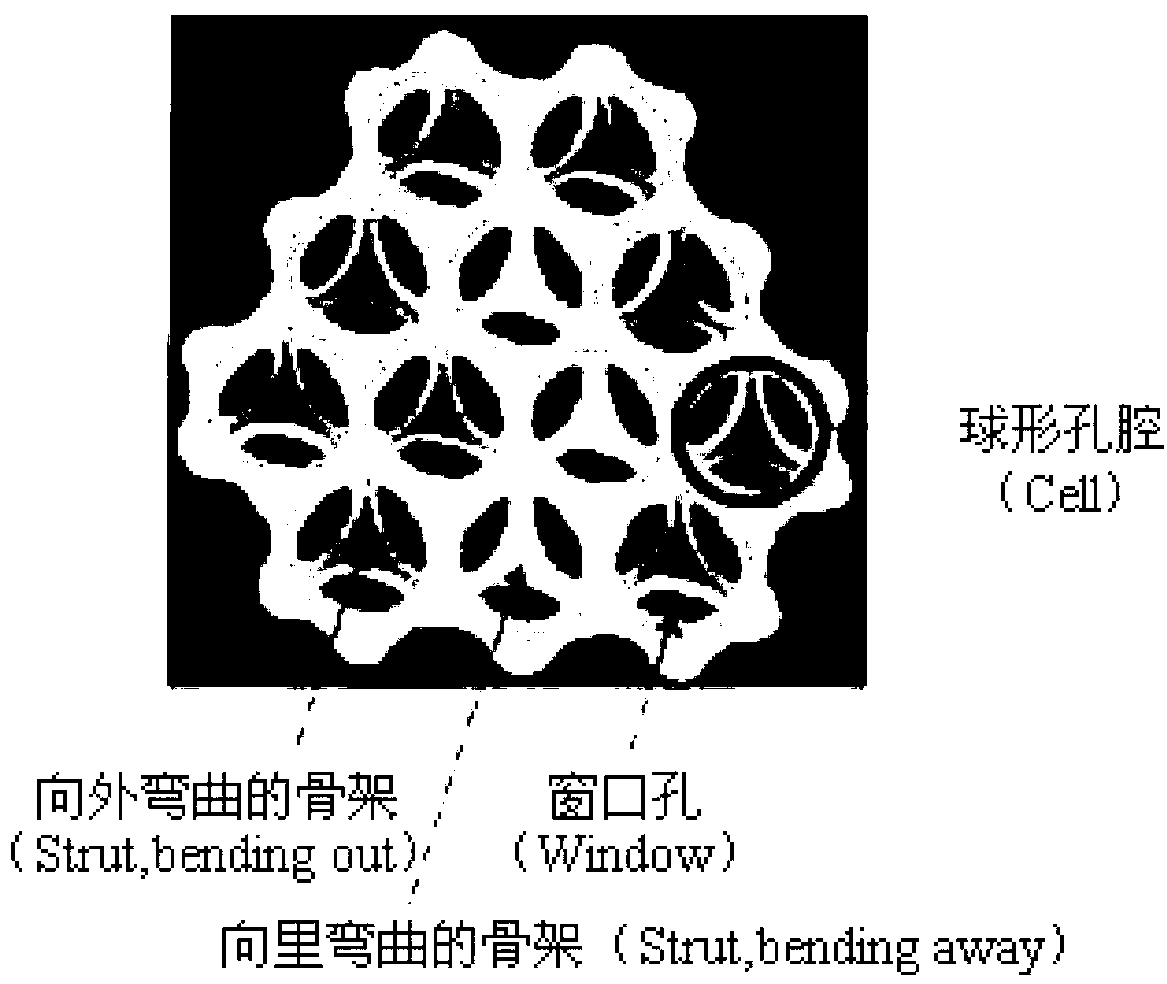

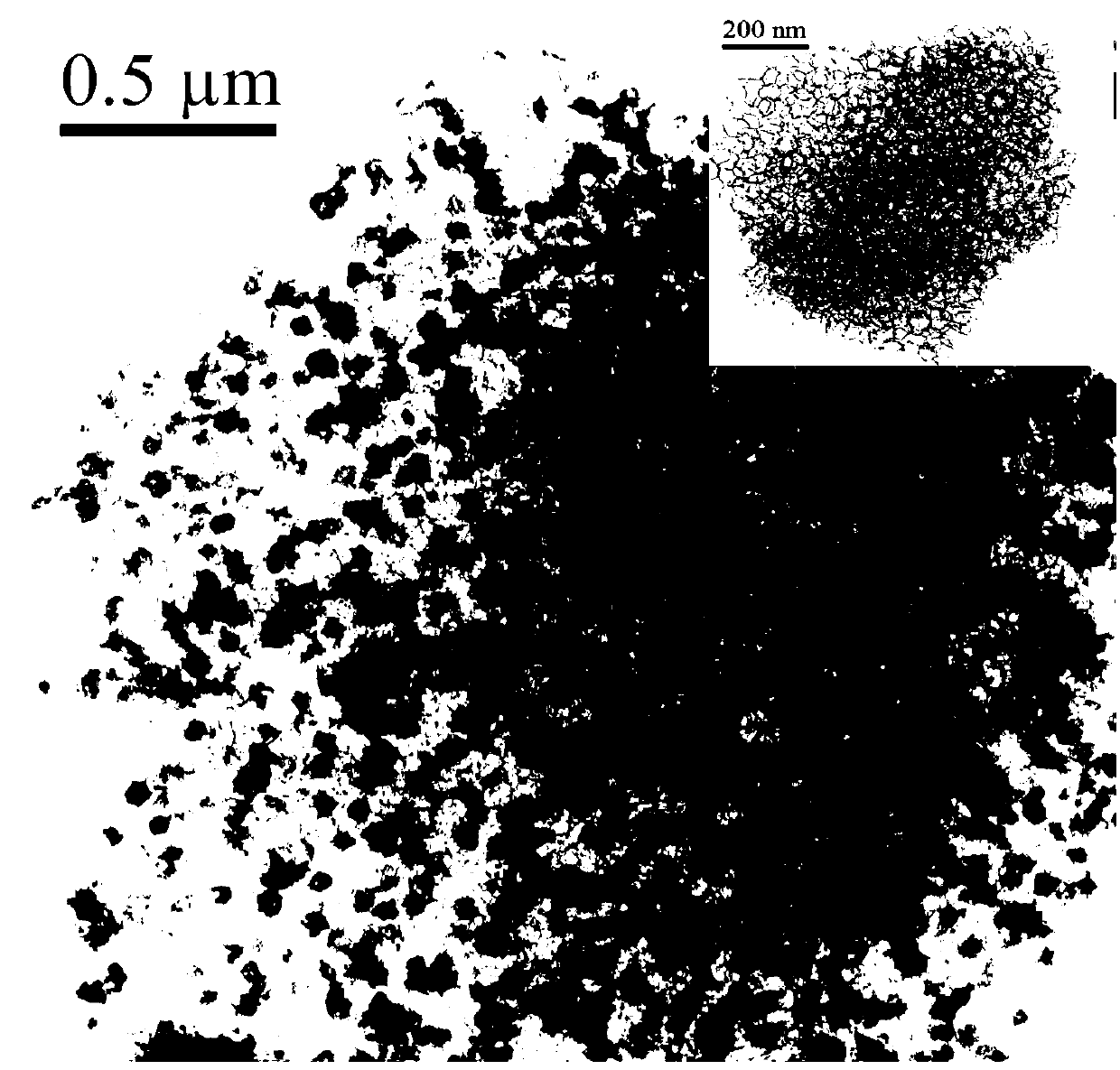

[0030] At room temperature, 6.00 g of triblock polymer surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , MA=5800) was dissolved in 210mL of 2mol / L hydrochloric acid, stirred for 1h, added 5.34mL of benzene, continued to stir for 1h, then added 13.50mL of tetraethyl orthosilicate (TEOS), stirred for 24h and transferred to polytetrafluoroethylene In a reaction tank, crystallize at 100°C for 24h, filter, wash and dry in the air, dry in an oven at 120°C for 12h, and finally bake at 550°C for 5h to obtain a carrier MCF (24) with a pore size of 24nm. The 24 after the MCF means the carrier is spherical The pore size of the pores is 24 nm.

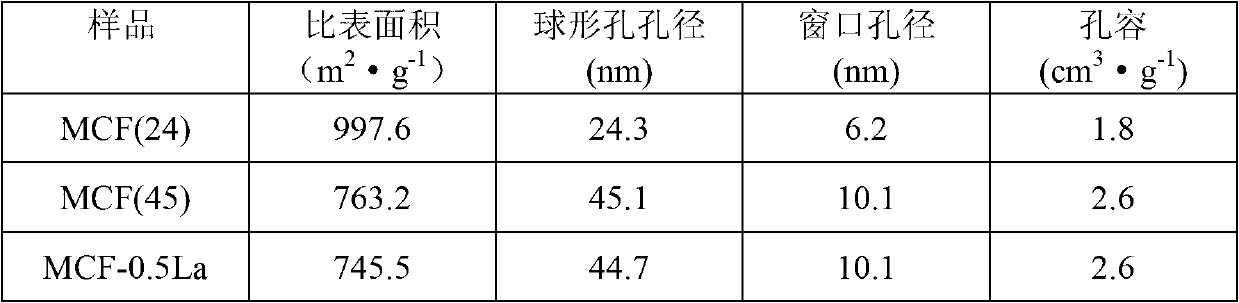

[0031] The pore structure parameters of the carrier MCF(24) were tested by a physical chemical adsorption instrument (Kanta, USA), and the results are shown in Table 1.

[0032] Take 2.00g of the above carrier, and impregnate the metal cobalt element by the full-hole impregnation method. Based on the mass fraction of the cobalt element in the final...

Embodiment 2

[0035] At room temperature, 6.00 g of triblock polymer surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , MA=5800) was dissolved in 210mL of 2mol / L hydrochloric acid, stirred for 1h, added 9.32mL of benzene, continued to stir for 1h, then added 13.50mL of tetraethyl orthosilicate (TEOS), stirred for 24h and transferred to polytetrafluoroethylene In a reaction tank, crystallize at 100°C for 24h, filter, wash and dry in the air, dry in an oven at 120°C for 12h, and finally bake at 550°C for 5h to obtain a carrier MCF (32) with a pore size of 32nm, where 32 means that the spherical pore size of the carrier is 32nm.

[0036] Take 2.00 g of the above carrier, and impregnate atomic cobalt with a mass fraction of 15% by the full-hole impregnation method. Dissolve 1.74g of cobalt nitrate hexahydrate in 5.50mL of distilled water, impregnate the solution evenly on the carrier, dry it in an oven at 120°C for 12h, and then bake it in a muffle furnace at 350°C for 5h in an air atmosphere. A...

Embodiment 3

[0039] At room temperature, 18 g of triblock polymer surfactant P123 (Aldrich, EO 20 PO 70 EO 20 , MA=5800) dissolved in 630mL of 2mol / L hydrochloric acid, stirred for 1h, added 39.90mL of benzene, continued to stir for 1h, then added 40.50mL of tetraethyl orthosilicate (TEOS), stirred for 24h and then transferred to polytetrafluoroethylene In a reaction tank, crystallize at 100°C for 24h, filter, wash and dry in the air, dry in an oven at 120°C for 12h, and finally bake at 550°C for 5h to obtain a carrier MCF (45) with a pore size of 45nm, where 45 means that the spherical pore size is 45nm.

[0040] The pore structure parameters of the carrier MCF (45) were tested by a physical chemical adsorption instrument, and the results are shown in Table 1.

[0041] Take 2.00 g of the above carrier and impregnate it with a full-pore impregnation method to prepare a catalyst with an atomic cobalt mass fraction of 15%. Dissolve 1.74g of cobalt nitrate hexahydrate in 6.50mL of distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com