Display module packaging structure and preparation method thereof

A display module and packaging structure technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of display devices not working properly, display module 12 damage, display module 12 erosion, etc., to achieve Inhibit the diffusion effect of the coating, improve the packaging effect, and inhibit the film layer from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Figure 2-7 It is a schematic flow diagram of preparing a display module packaging structure in the embodiment of the present application; as Figure 2-5 As shown, the present application provides a method for preparing a display module packaging structure, which may include the following steps:

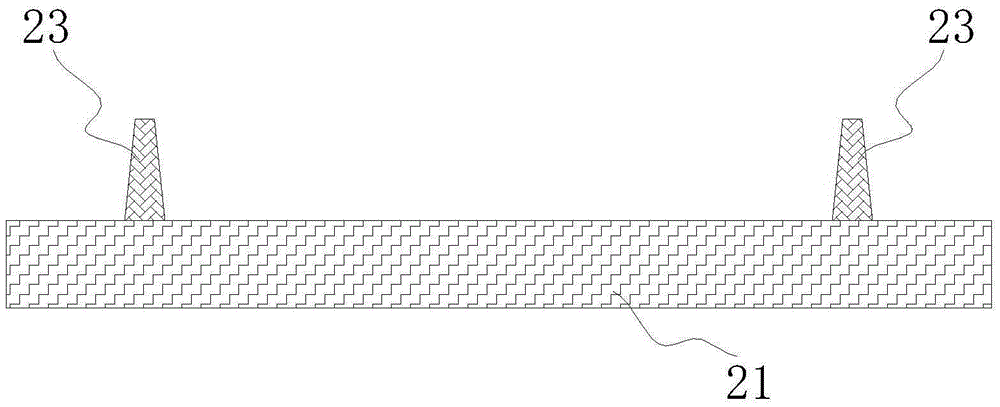

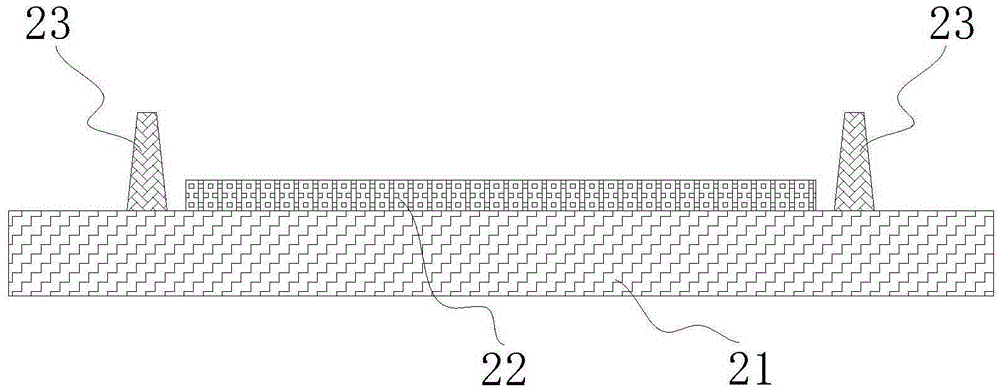

[0075] First, if figure 1 As shown, based on a base substrate (such as a low temperature polysilicon (LowTemperature PolySilicon, LTPS) substrate), the display device array (array) process is performed to form the array substrate 21; the above-mentioned array substrate 21 can be provided with In the display area and the non-display area set adjacent to the display area, the array substrate 21 in the display area is mainly used for attaching and preparing display devices; at the same time, thin film transistors can also be arranged on or in the array substrate 21 The display circuit is used to drive the subsequent display module to work.

[0076] In addition, during the abov...

Embodiment 2

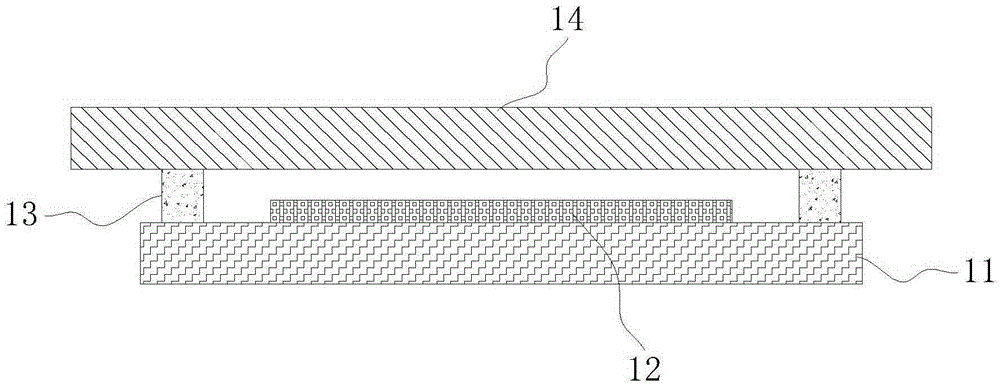

[0096] Can be based on the basis of the first embodiment above, such as Figure 7 As shown, the embodiment of the present application also provides a display module packaging structure, and the display module packaging structure can be used to prepare various display devices (such as OLED display devices, etc.), the above-mentioned display module packaging structure includes:

[0097] The array substrate 21 can be a substrate for completing the array (array) process, and can include but not limited to an LTPS substrate, etc.; the array substrate 21 can have a front surface for setting devices (i.e. Figure 5 shown in the upper surface) and the lower surface relative to the upper surface (ie Figure 5 , 6 The lower surface shown in ); the material of the substrate can be selected as glass, and the array substrate 21 can also be formed with a hard substrate or a flexible substrate, and the array substrate 21 can be provided with a device for driving a display module. Light-emi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com