Solar selective absorption coating and preparing method thereof

An absorbing coating and selective technology, applied in solar thermal power generation, coatings, solar thermal devices, etc., can solve the problems of time-consuming process, enhanced thermal diffusion, and decreased coating performance, so as to improve high temperature stability, Effect of preventing thermal diffusion and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

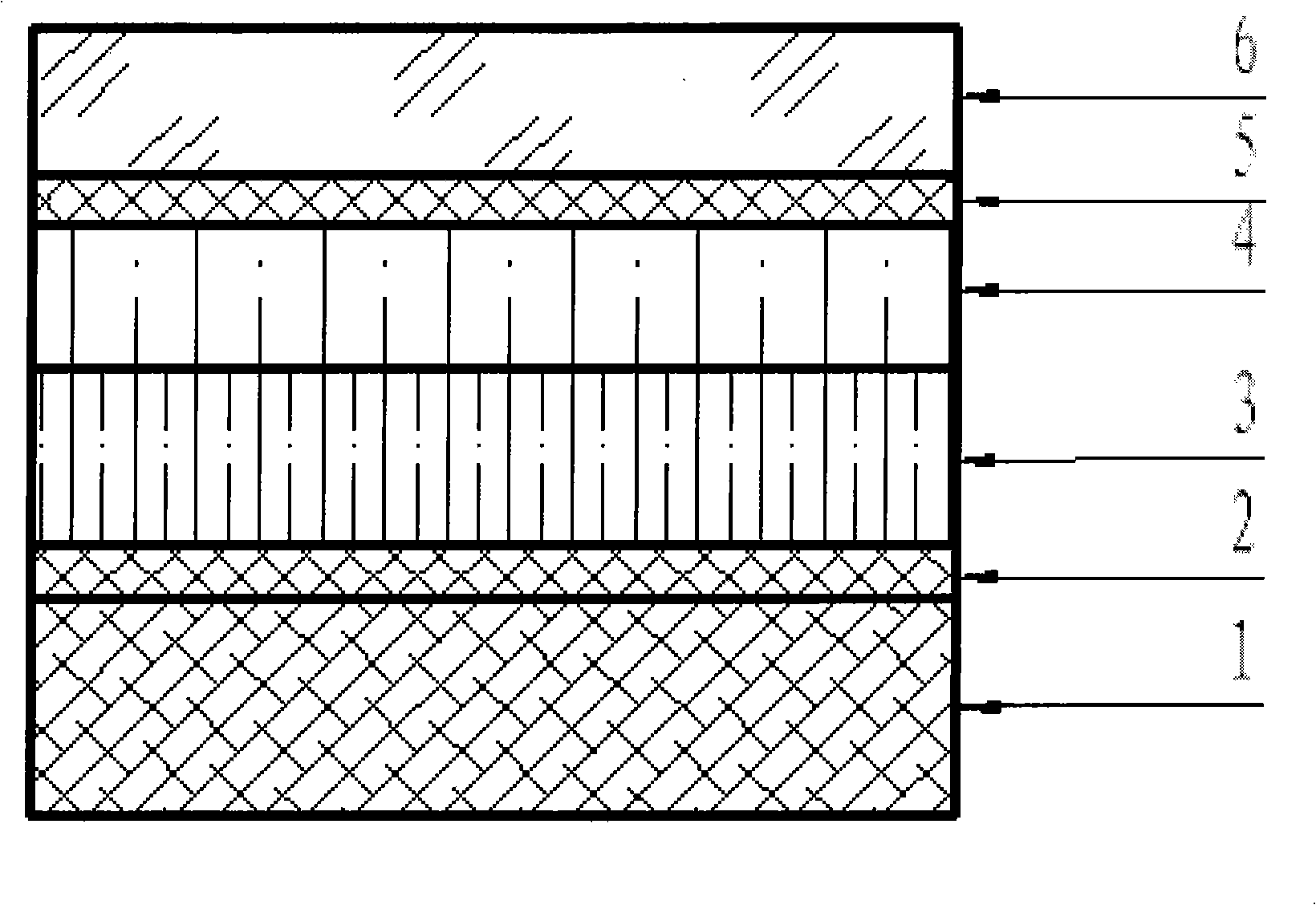

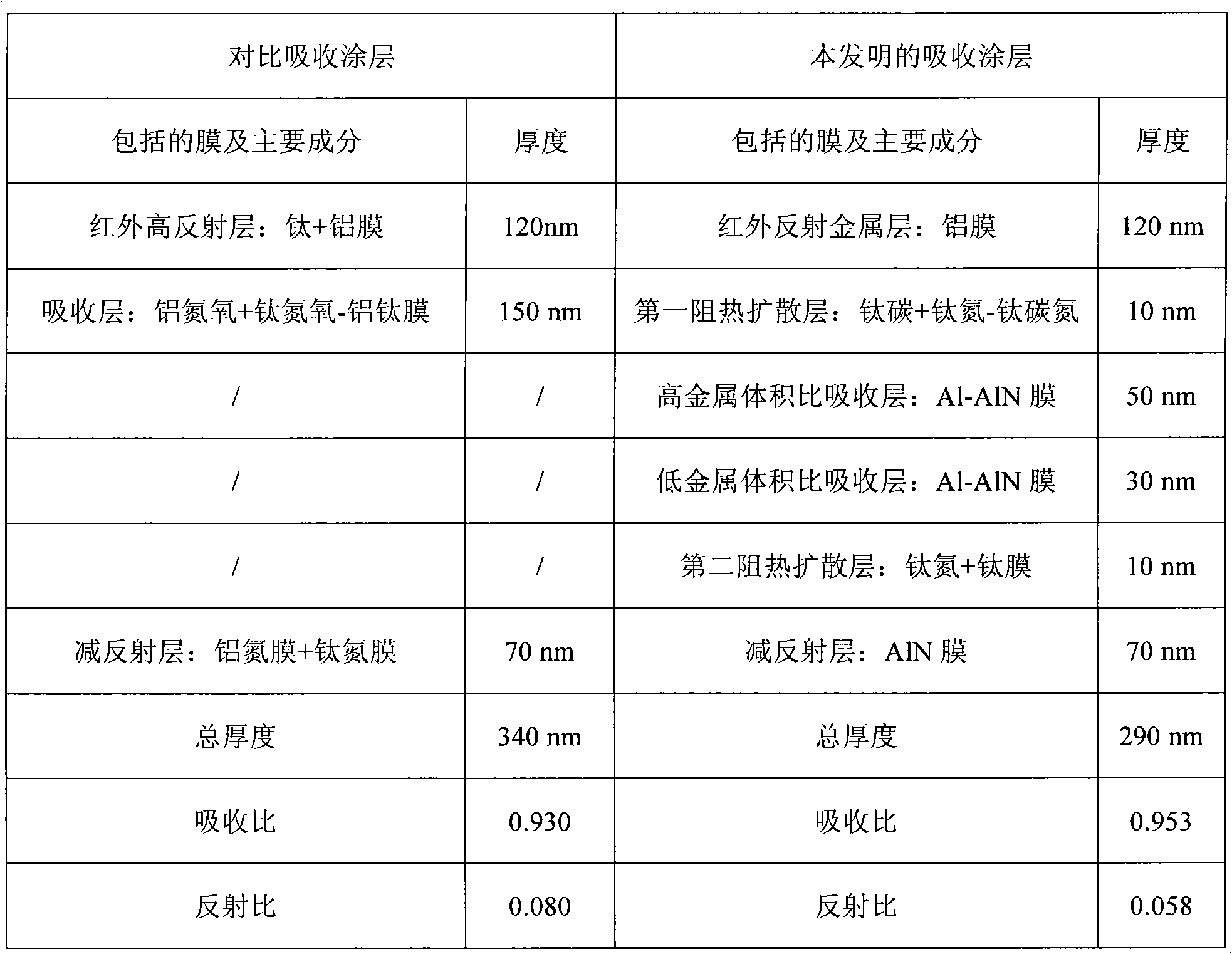

[0029] Take the Al-AlN film system as an example: figure 1 It can be seen that the solar selective absorption coating of the present invention is divided into 6 layers from the bottom to the top of the glass substrate, which are the high infrared reflection metal bottom layer 1, the first heat resistance diffusion layer 2, the high metal volume ratio absorption layer 3, and the low metal Volume ratio absorption layer 4 , second heat-resistant diffusion layer 5 and anti-reflection layer 6 . Argon gas was introduced into the coating machine, the aluminum target was opened, and the aluminum film was made by non-reactive sputtering of argon gas as the high-infrared reflection metal bottom layer 1 with a thickness of 120 nm; the Ti target was used in the mixed gas of argon, nitrogen and methane. Medium reactive sputtering to form the first resistance thermal diffusion layer 2 composed of titanium carbon + titanium nitrogen - titanium carbon nitrogen (TiC + TiN - TiCN), the thicknes...

Embodiment 2

[0032] Take the SS-AlN film system as an example: the selective absorption coating is divided into 6 layers from the bottom to the top of the glass substrate. The first layer is a high-infrared reflection metal layer. Argon gas is passed into the coating machine, the copper target is opened, and the copper metal bottom layer is plated. The second layer is the first thermal diffusion resistance layer, which is formed by reactive sputtering using a Ti target in a mixed gas of argon, nitrogen and acetylene to form a titanium carbon + titanium nitrogen - titanium carbon nitrogen (TiC + TiN - TiCN) thermal diffusion resistance layer. , the thickness of this layer is 5nm, and the molar ratio of TiC, TiN and TiCN is 1:3:4. The third layer is a high metal volume ratio absorbing layer, which is formed by reactive sputtering using an aluminum target and a stainless steel target in a mixed gas of argon and nitrogen. The ratio of argon to nitrogen is 1:1, forming a high metal volume ratio...

Embodiment 3

[0035]Take the Al-AlN film system as an example: the selective absorption coating is divided into 6 layers from the bottom to the top of the glass substrate. The first layer is a high-infrared reflection metal layer. Argon gas is introduced into the coating machine, the aluminum target is opened, and the aluminum metal bottom layer is plated. The metal aluminum film with a thickness of 100nm is sputtered by argon gas non-reactive sputtering. The second layer is the first thermal diffusion resistance layer, which uses a Ti target to react and sputter in a mixed gas of argon, nitrogen and butane to form titanium carbon + titanium nitrogen - titanium carbon nitrogen (TiC + TiN - TiCN) for thermal diffusion resistance. layer with a thickness of 8 nm and a molar ratio of TiC, TiN and TiCN of 1:2:5. The third layer is a high metal volume ratio absorption layer, which is formed by reactive sputtering using an aluminum target in a mixed gas of argon and nitrogen. The ratio of argon to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com