Secondary lens with bottom of curved surface structure

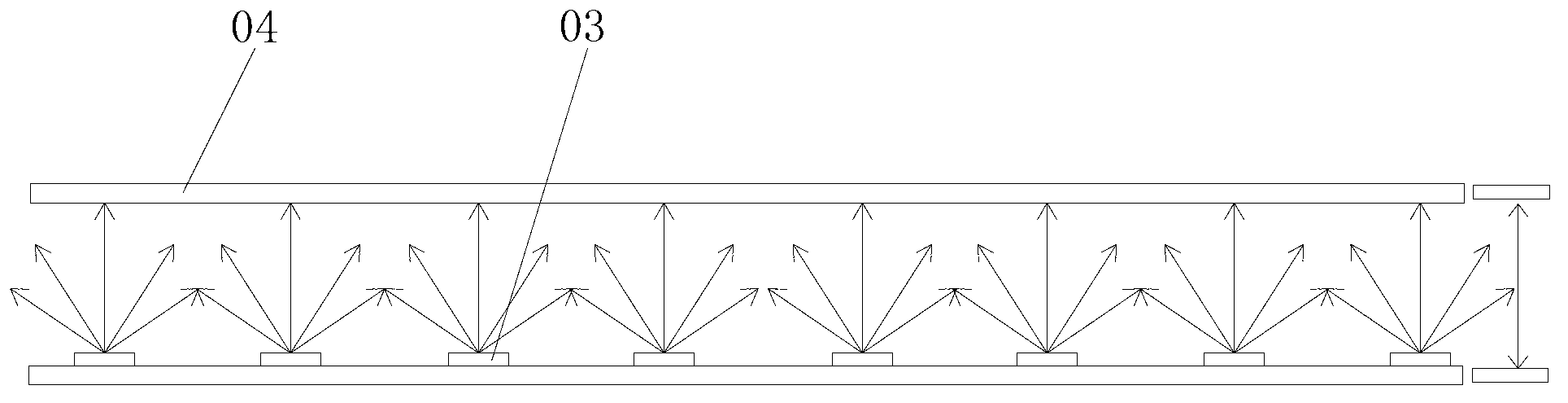

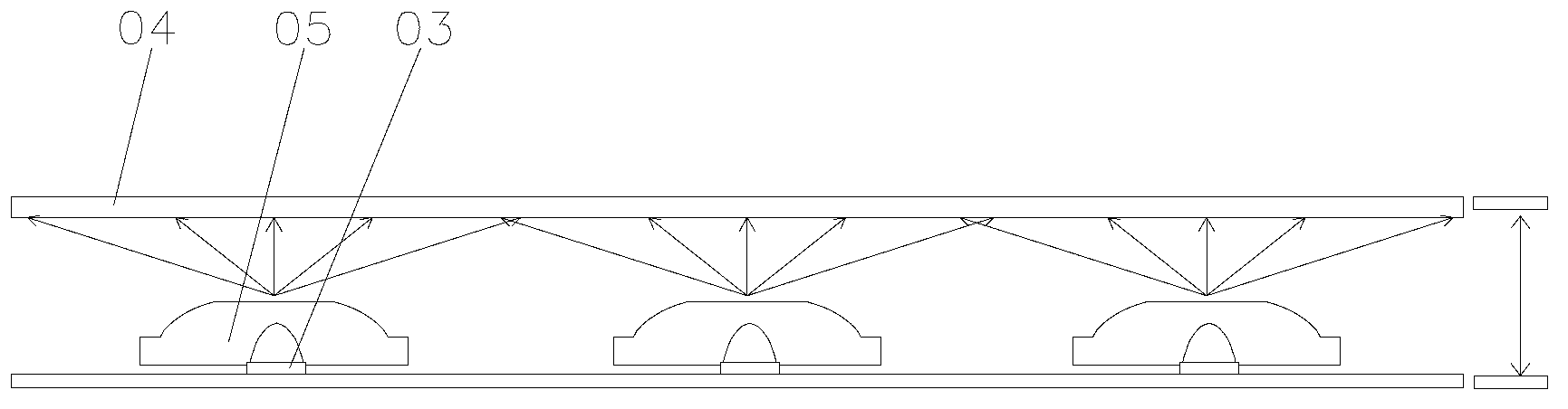

A technology of secondary lens and curved surface structure, applied in the direction of condenser lens, illuminated mark, parts of lighting device, etc., can solve the problems of light intensity, uneven light distribution, etc. good diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

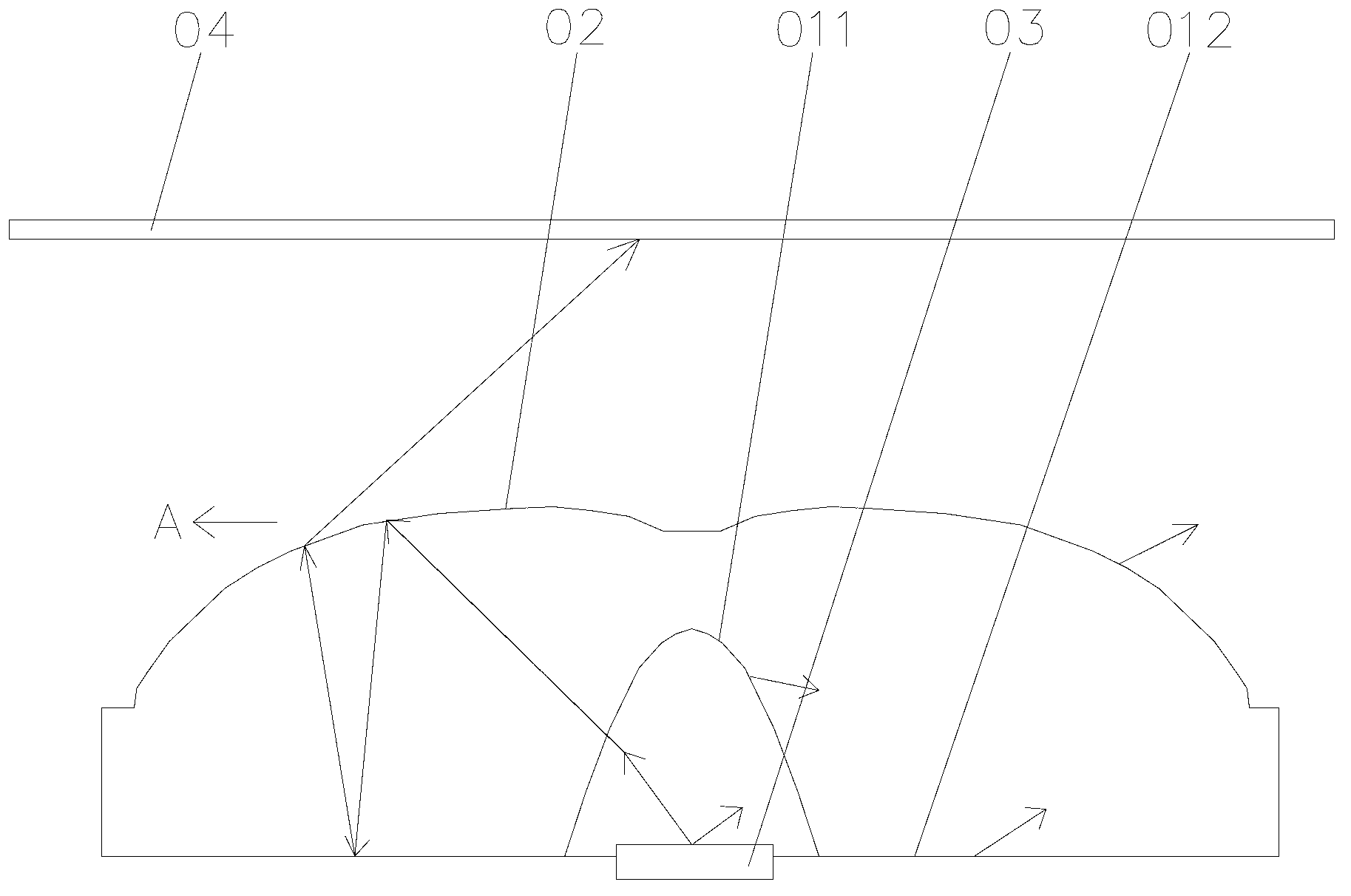

Embodiment 1

[0051] Such as Figure 5 As shown, the connection between the light incident surface 11 and the concave curved surface 12 at the bottom surface 1 is a circle of horizontal planes 5, which not only facilitates the processing of the connection between the light incident surface 11 and the concave curved surface 12, but also facilitates the bottom surface 1 and the point. Fixing of the light source 3; the connection between the light emitting surface 2 and the concave curved surface 12 at the bottom surface 1 is a circle of horizontal planes 6, so as to facilitate the processing of the connection between the light emitting surface 2 and the concave curved surface 12.

Embodiment 2

[0053] Such as Image 6 As shown, the connection between the light exit surface 2 and the bottom surface 1 at the side is a circle of vertical surfaces 7, which not only facilitates the processing of the connection between the light exit surface 2 and the concave curved surface 12, but also facilitates the side fixation of the secondary lens.

Embodiment 3

[0055] Such as Figure 7 As shown, the connection point i between the concave curved surface 12 and the light incident surface 11 is the lowest point of the bottom surface, so that the light emitted by the point light source 3 passes through the light incident surface 11, and the light source utilization rate is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com