Large-spreading-angle foam fire-extinguishing sprayer

A foam fire extinguishing and diffusion angle technology, applied in fire rescue and other directions, can solve problems such as failure to deal with foam foaming oil pool fire in time, uneven distribution of foam mixture, affecting the efficacy of fire extinguishing system, etc., achieving no maintenance costs and coverage. Moreover, the effect of high spray intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

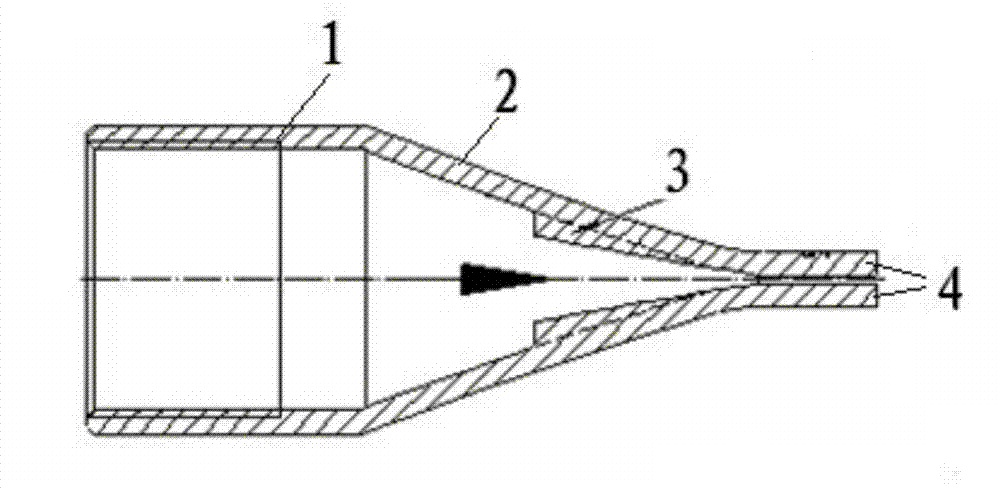

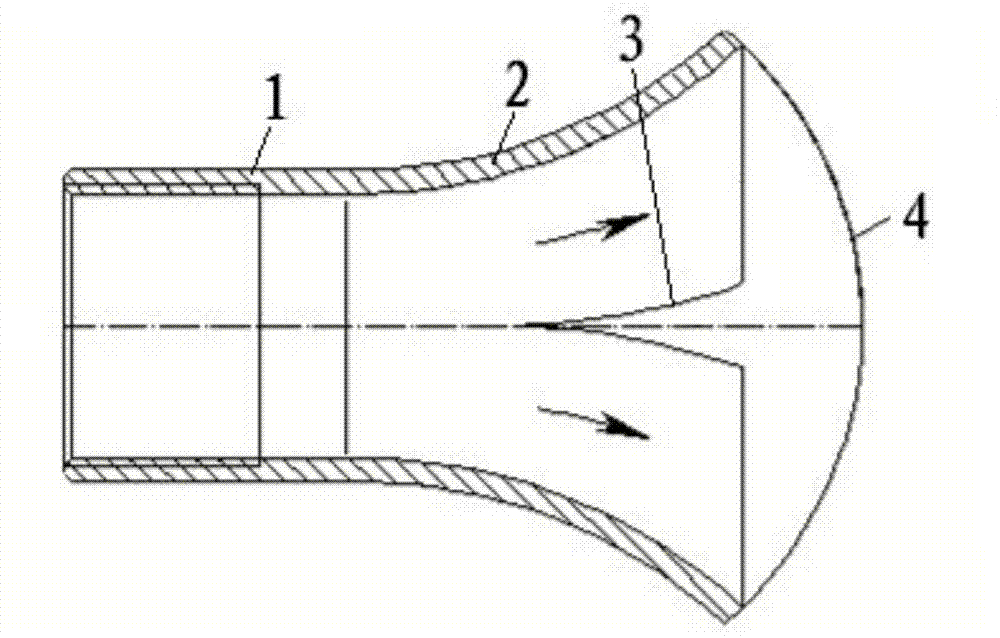

[0020] refer to figure 1 , is a schematic diagram of a full-section structure of a large-diffusion-angle foam fire-extinguishing nozzle of the present invention; the fire-extinguishing nozzle includes a cylindrical nozzle body 1, a wedge-shaped nozzle 2 is provided at the outlet of the nozzle body 1, and the inner upper part of the outlet of the wedge-shaped nozzle 2 Wedge guide blocks 3 are respectively arranged symmetrically on the side and the inner lower side, the cross section of the wedge shape guide blocks 3 is an isosceles triangle, and the center line of the wedge shape guide blocks 3 coincides with the center line of the wedge nozzle 2, as image 3 As shown; the upper side and the lower side of the outlet end of the wedge-shaped nozzle 2 are respectively symmetrically provided with stabilizing plates 4 .

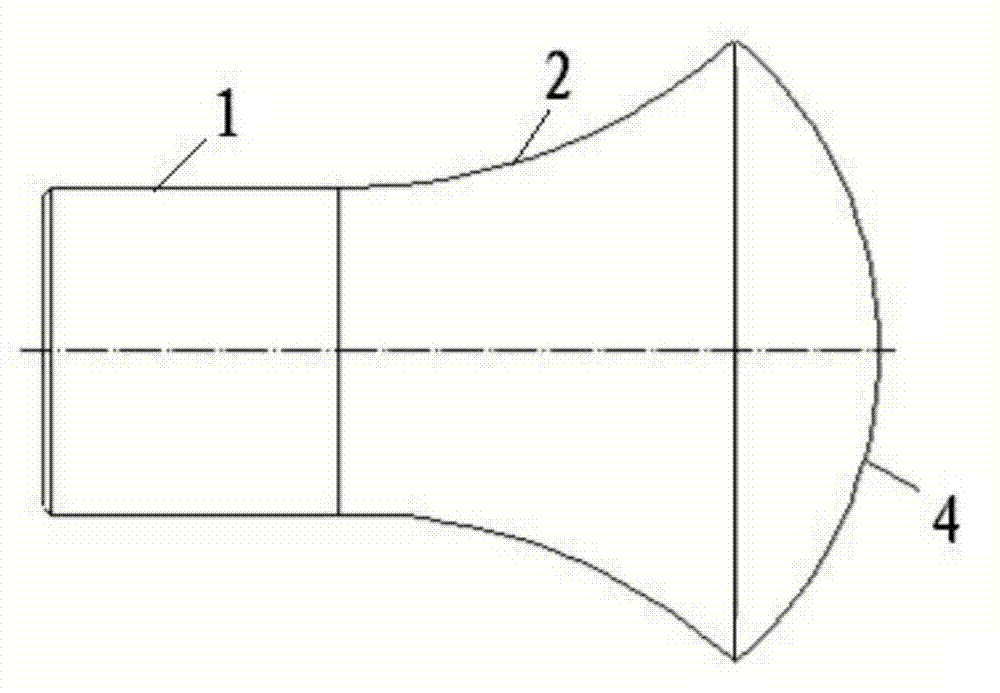

[0021] Wherein, the front side and the rear side of the wedge-shaped nozzle 2 are respectively set in an outwardly expanding circular arc shape, such as figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com