Ultra-enthalpy plasma composite combustion-supporting combustion test device for low-concentration combustible gas at atmospheric pressure

A plasma and combustion test technology, which is applied in the direction of chemical analysis by means of combustion, can solve problems such as waste, increased system risk, energy consumption, etc., achieve good combustion-supporting effect, broaden the ignition limit, and reduce the super-enthalpy preheating temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

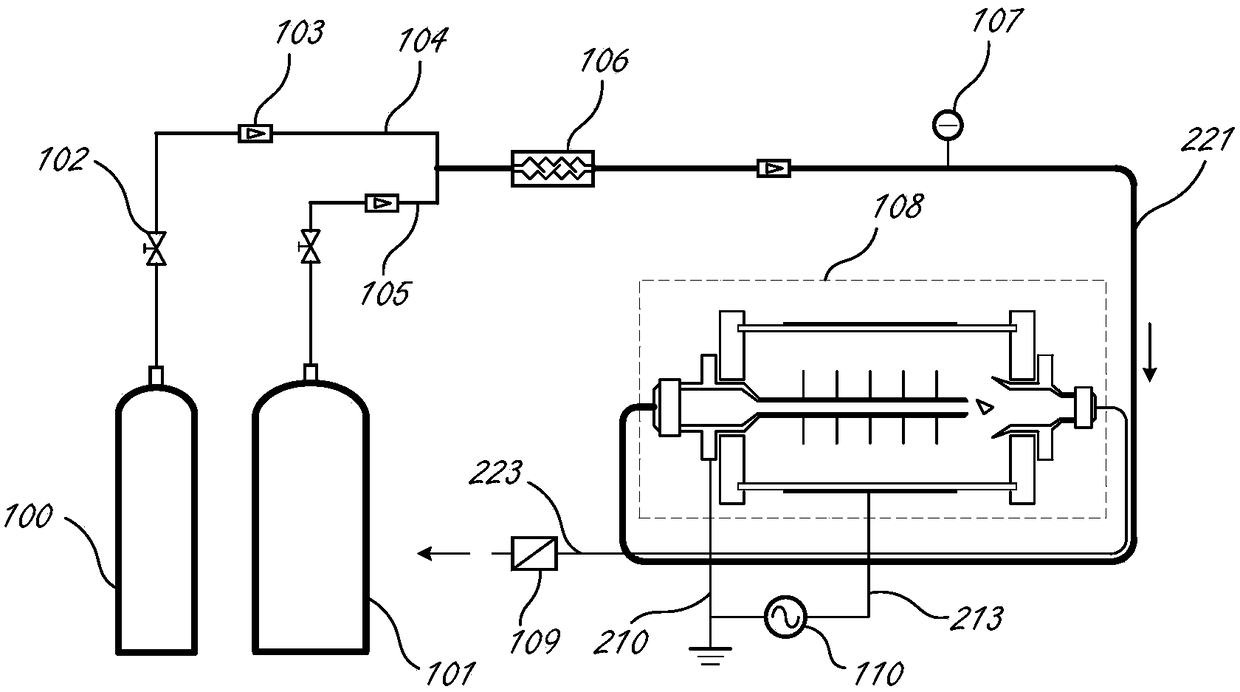

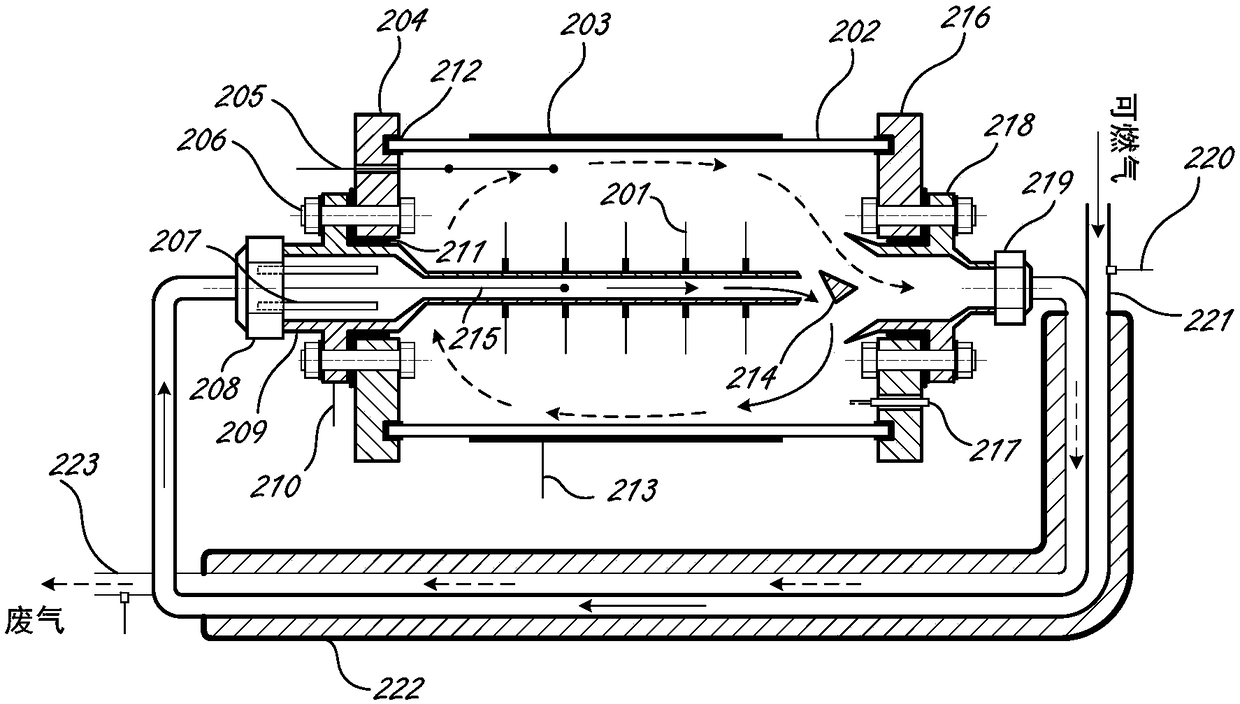

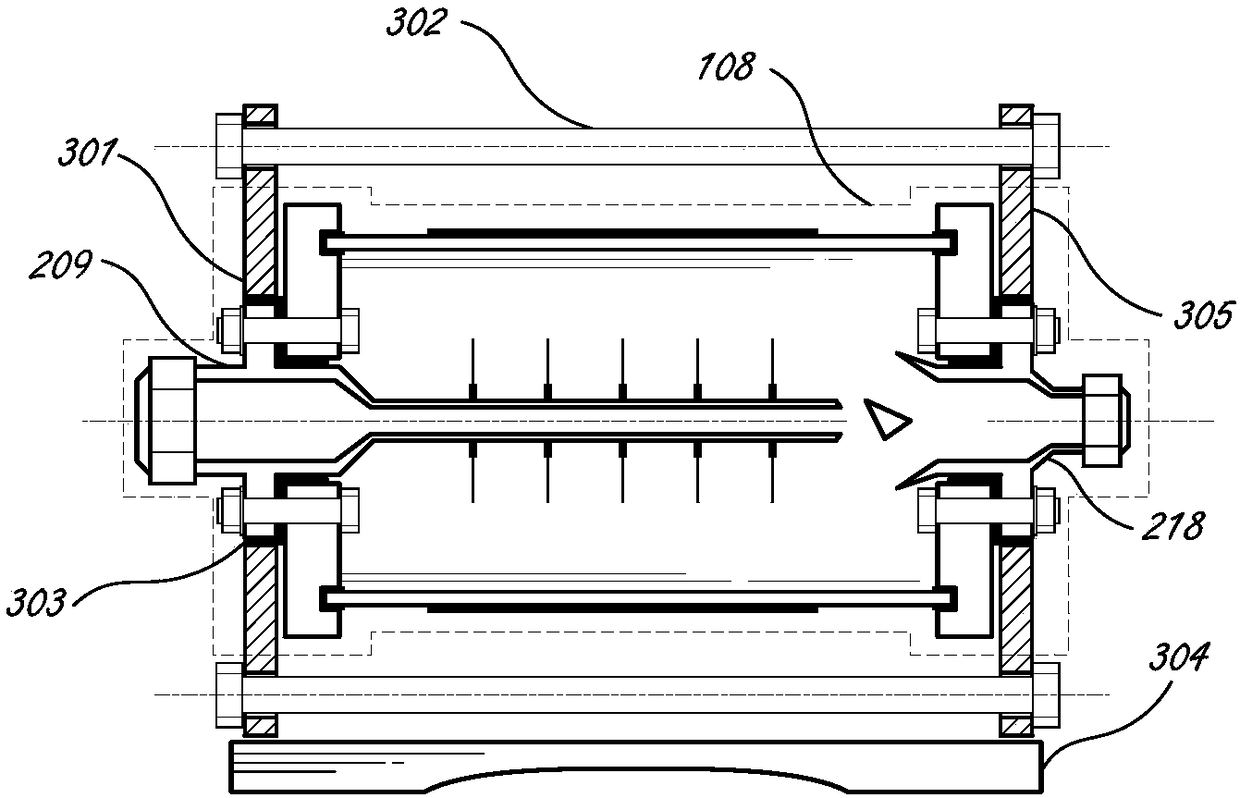

[0033] figure 1 A schematic side view of the structure of an ultra-enthalpy plasma composite combustion-supporting combustion test device at atmospheric pressure and low-concentration combustible gas of the present invention is given, figure 2 It is a schematic diagram of the main structure of the burner in the combustion test device, image 3 It is a side view of the fastening and placement of the burner body.

[0034] Such as figure 1 As shown, a bottle of compressed high-purity combustible gas source 100 and a bottle of compressed air source 101 pass through the combustible gas branch pipeline 104 and the air branch pipeline 105 respectively, and a pressure reducing valve 102 and a mass flow meter are respectively connected in series in sequence. 103. For example, the compressed high-purity combustible gas source 100 selected in this embodiment is a 10-liter 5Mpa high-concentration methane cylinder, the compressed air source 101 is a 30-liter 10Mpa air cylinder, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com